42 Planning the electrical installation

Note 7:

Resistor braking of the drive

When the drive is in braking mode for a large part of its operation time, the

intermediate circuit DC voltage of the drive increases, the effect being similar to

increasing the supply voltage by up to 20 percent. Consider the voltage increase

when you determine the motor insulation requirement.

Example: Motor insulation requirement for a 400 V application must be selected as if

the drive were supplied with 480 V.

Note 8:

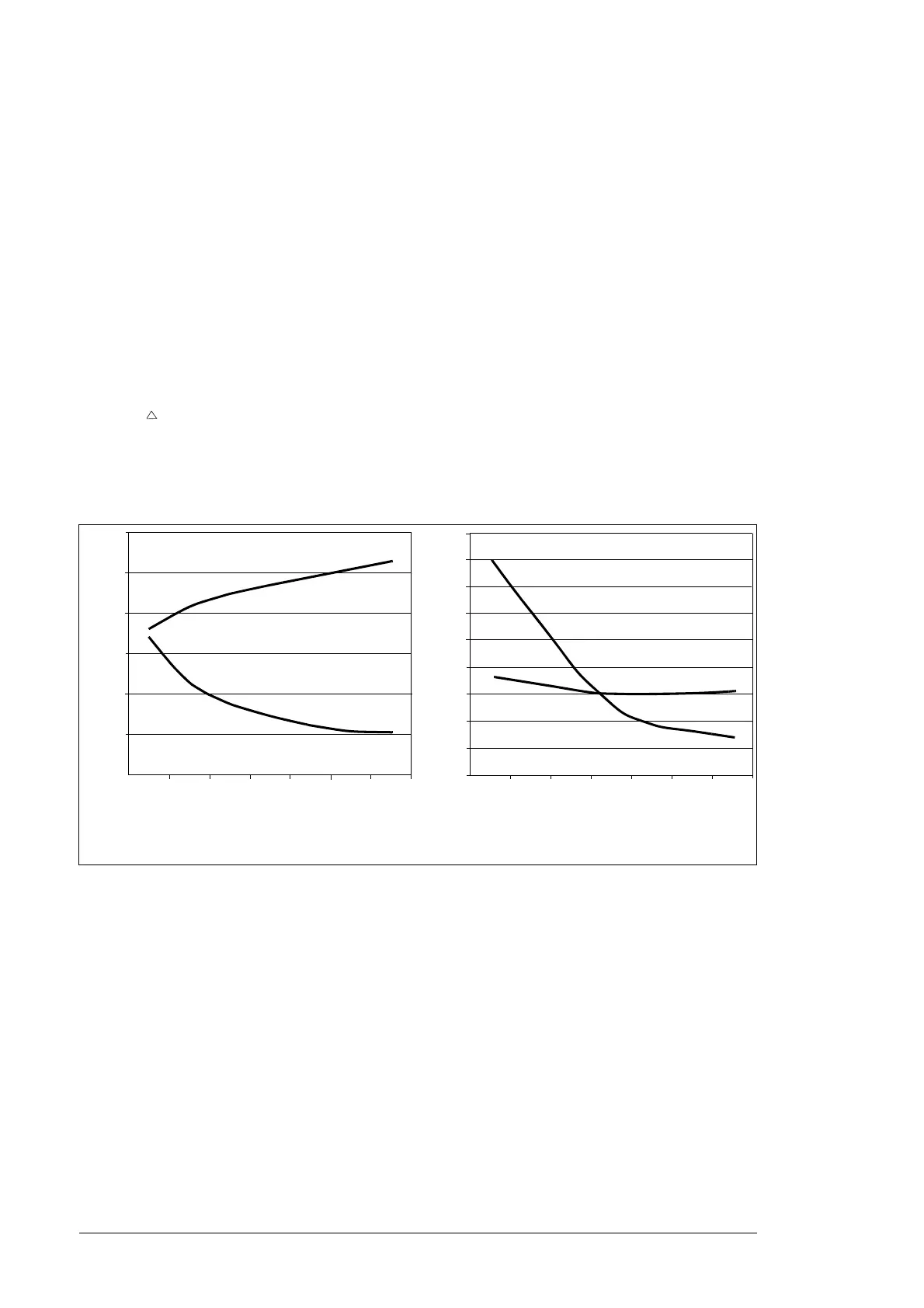

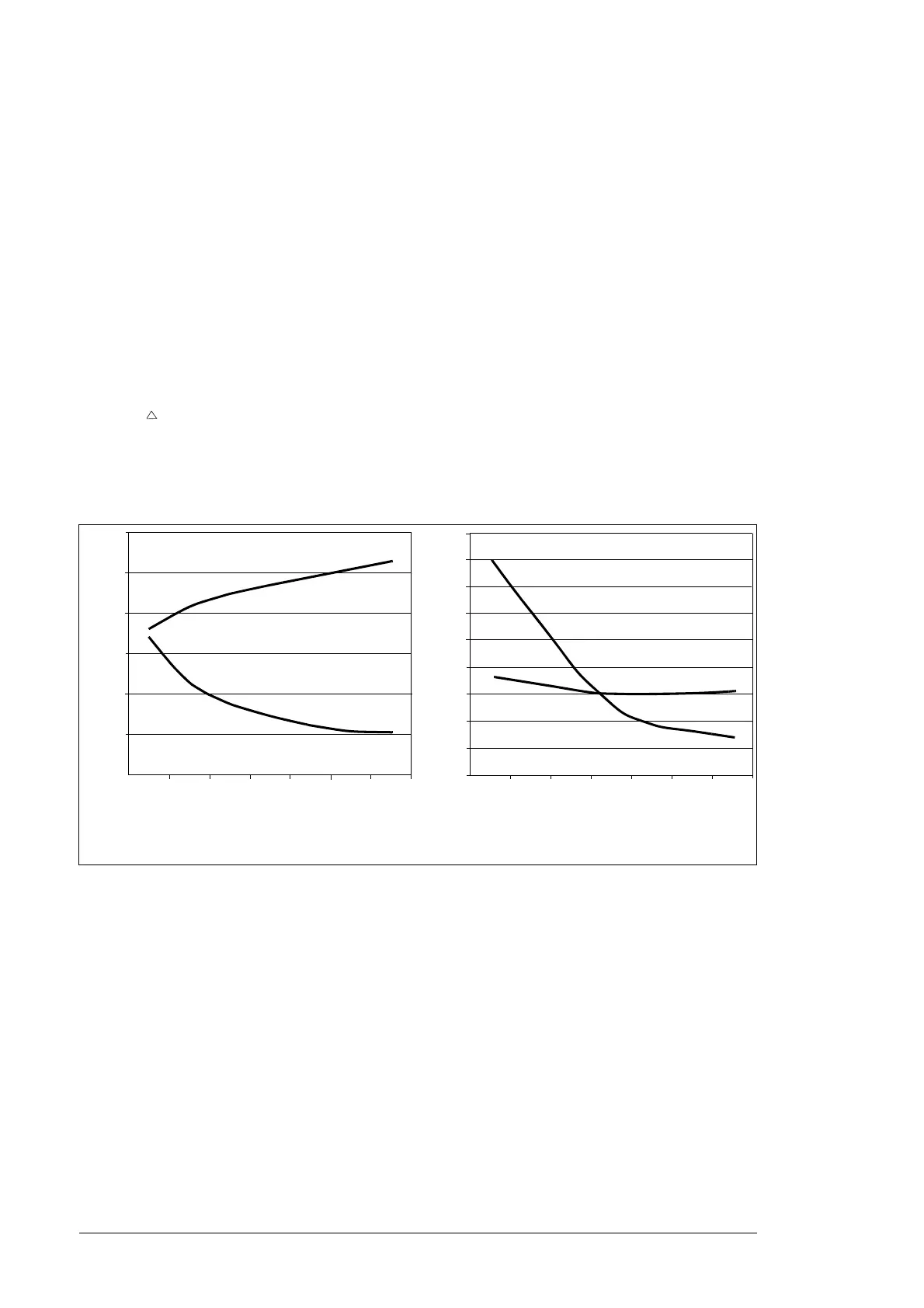

Calculating the rise time and the peak line-to-line voltage

The peak line-to-line voltage at the motor terminals generated by the drive as well as

the voltage rise time depend on the cable length. The requirements for the motor

insulation system given in the table are “worst case” requirements covering

installations with 30 meter and longer cables. The rise time can be calculated as

follows: t = 0.8 ·

Û

LL

/(d

u

/d

t

). Read

Û

LL

and d

u

/d

t

from the diagrams below.

M

ultiply

the values of the graph by the supply voltage

(

U

N

)

. In case of drives with an

IGBT supply unit or resistor braking, the

Û

LL

and d

u

/d

t

values are approximately

20 % higher.

Note 9: Sine filters protect the motor insulation system. Therefore, d

u

/d

t

filter can

be replaced with a sine filter. The peak phase-to-phase voltage with the sine filter is

approximately 1.5 ×

U

N

.

Note 10: Common mode filter is available as a separate option.

Permanent magnet motor

You can connect only one permanent magnet motor to the inverter output.

ABB recommends a safety switch between the permanent magnet motor and the

drive output. The switch isolates the motor during maintenance work.

Û

LL

/U

N

Without du/dt Filter

Cable length (m)

du/dt

U

N

-------------(1/s)

1.0

2.0

5.0

4.0

3.0

1.5

2.5

3.5

4.5

100 200 300

100 200 300

0.0

0.5

1.0

1.5

2.0

2.5

3.0

Cable length (m)

With du/dt Filter

du/dt

U

N

-------------(1/s)

Û

LL

/U

N

5.5

Loading...

Loading...