____________________________________________________________________________________________________________

V2 AC500 Hardware 1-56 System data AC500 / Issued: 05.2007

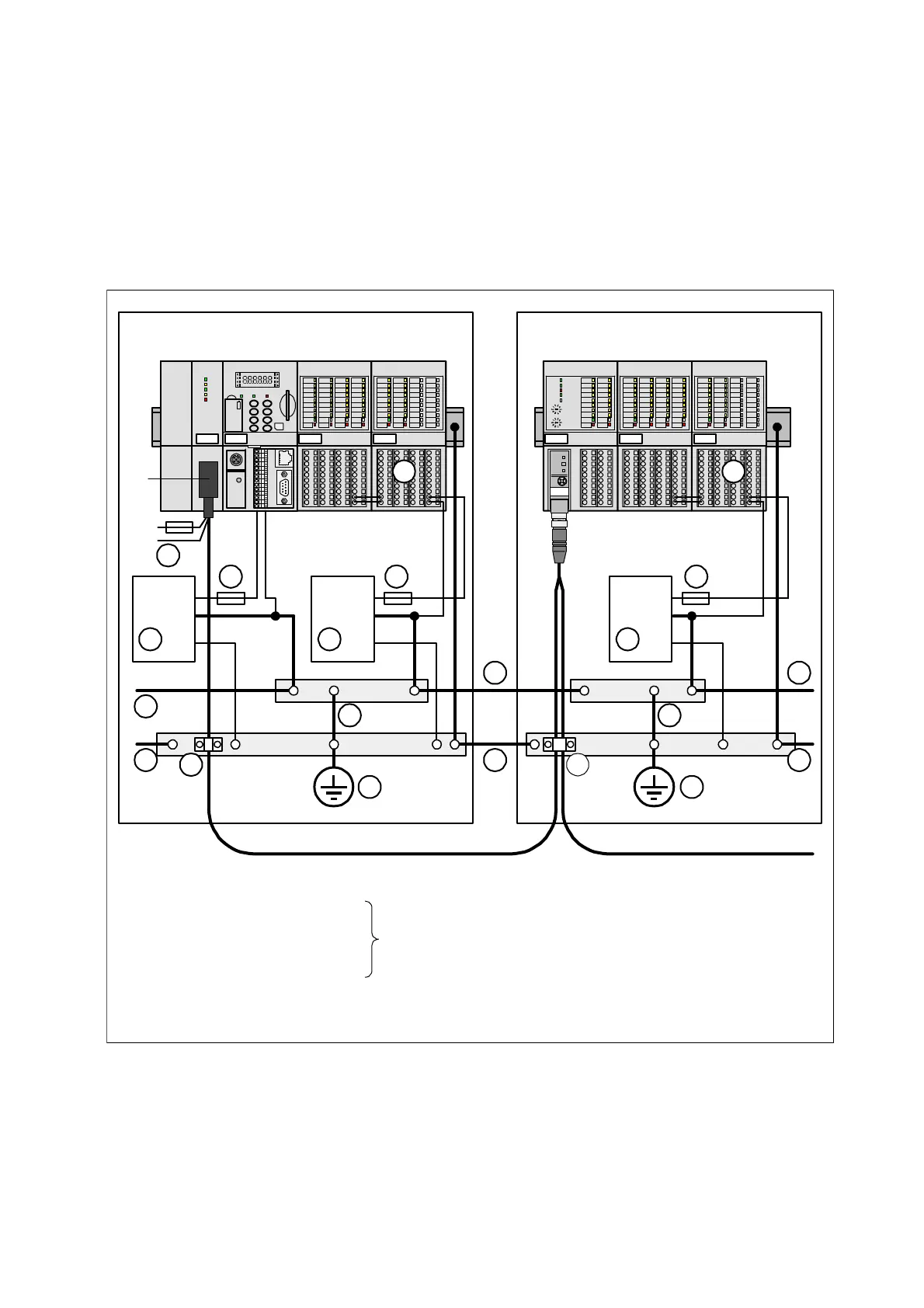

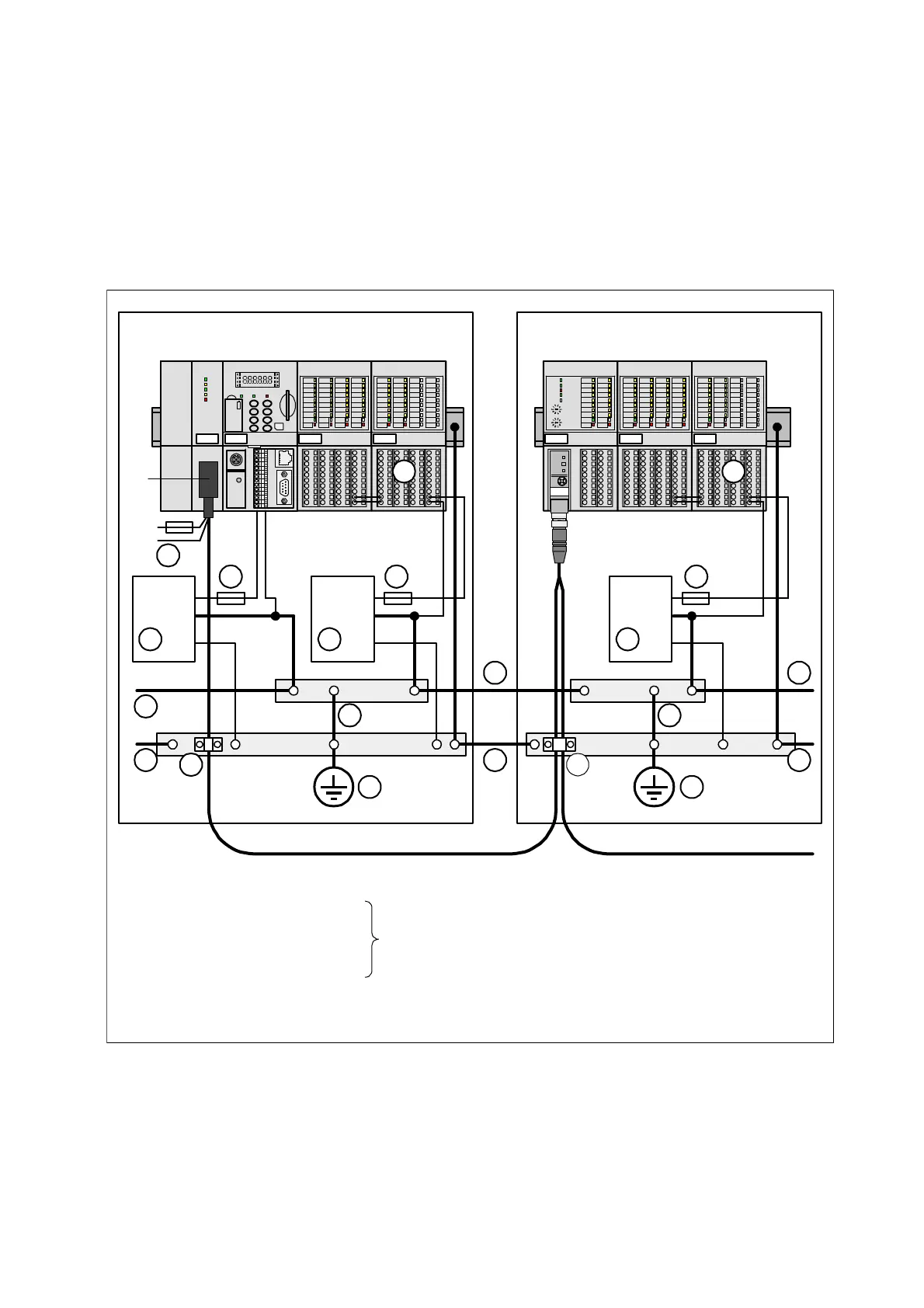

Equipotential bonding

• Install sufficiently dimensioned equipotential bondings, if potential differences are present or have to

be expected in your application between different parts of the installation.

• The impedance of a equipotential bonding must be equal or lower than 10 % of the shield

impedance of the shielded signal cables between the same points.

• The conductor cross section of a equipotential bonding must be able to withstand the maximum

possible compensating current. By experience, a conductor cross section of 16 mm² has proven to

be sufficient.

• Equipotential bondings and shielded signal cables should be laid close to each other. This prevents

coming up inductive loops in which disturbances could be induced.

• Equipotential bondings must be connected to PE with low impedance.

DX522DC532 DX522DC532

AC500 S500

24V

DC

+

–

PE

Cabinet 1 Cabinet 2

24V

DC

+

–

PE

3

7

10

11

6

5 5

8

9 9

11

DIN rail

1 24V power supply FBP

2 Power supply for the CPU

6 For fuses for the contacts of the relay outputs

see the descriptions of the relevant modules

8 Earthing of the 0V rail

9 Cabinet earthing

10 Equipotential bonding

between the cabinets min. 16 mm

11 Cable shields earthing

2

1010

8

6

24V

DC

+

–

PE

7

7

0V 0V

PE PE

DC505

24V

0V

1

2 4

5 Fuse for the I/O modules power

3 Fuse for the CPU power

4 Power supply for the I/Os

only one power

possible

supply is also

7 0V rail (reference potential for signals)

with terminating resistor

4

Figure: AC500, equipotential bondings

Loading...

Loading...