9

Twin Wash Nozzles

Maintenance

Cleaning

Screw

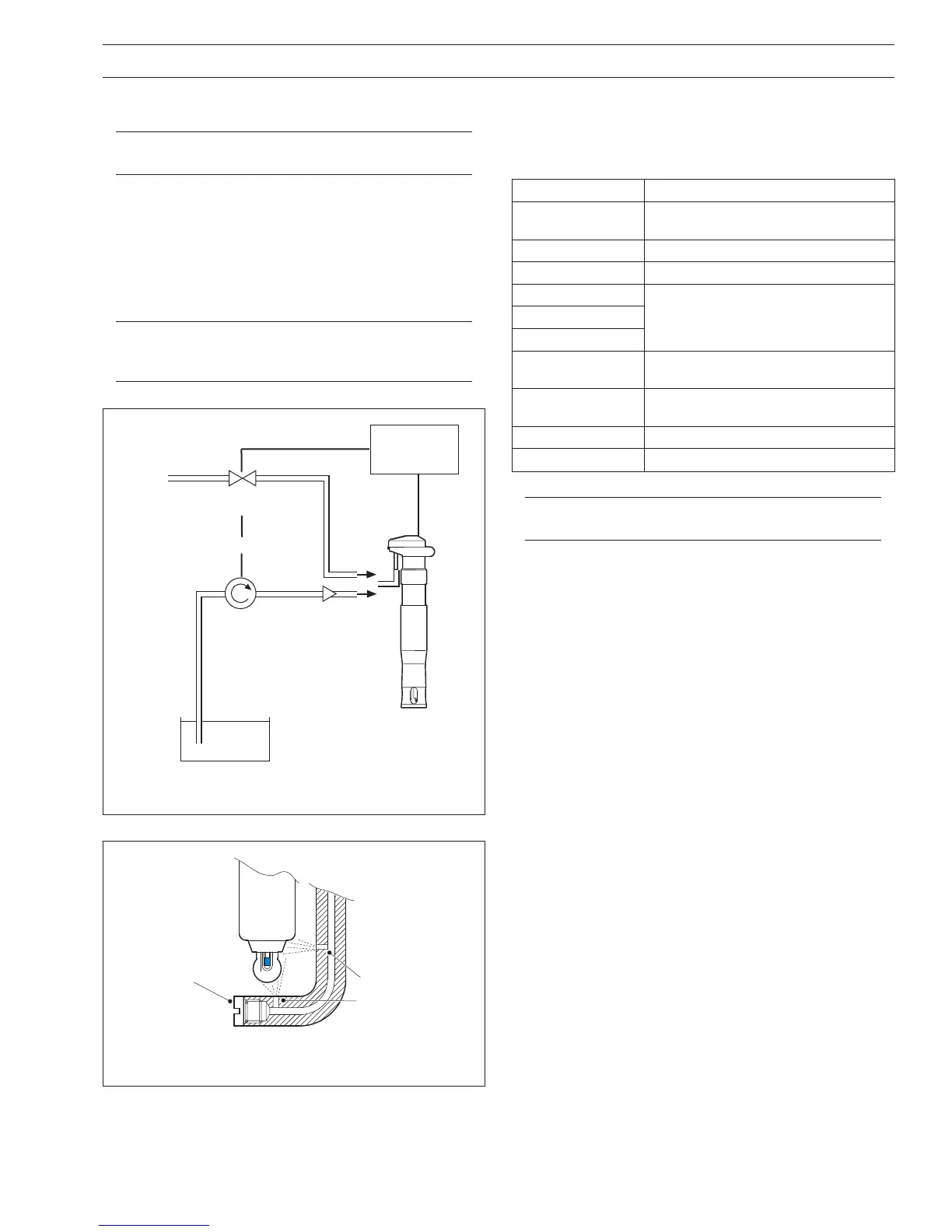

Fig. 2.7 Typical Jetwash Installation

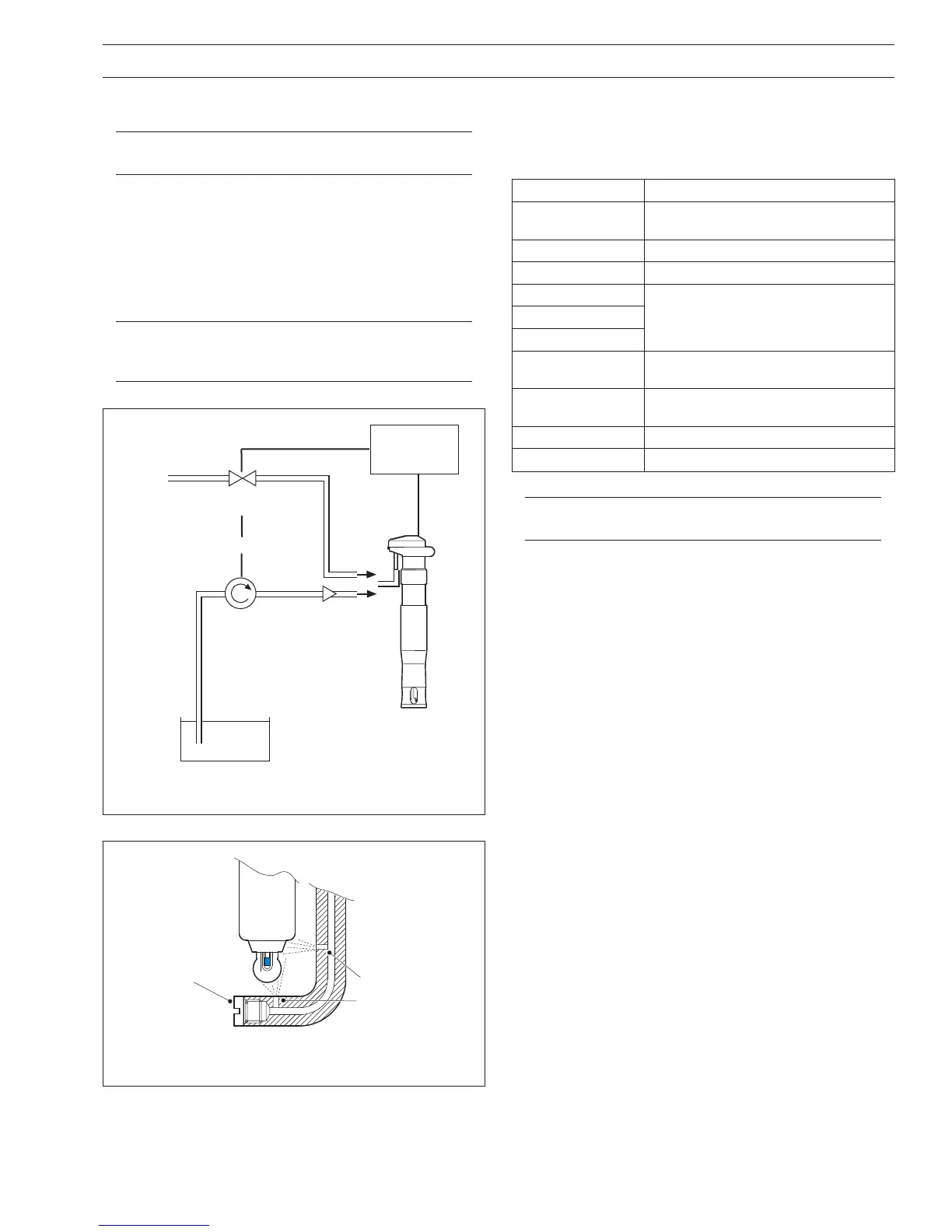

Fig. 2.8 Location of Jetwash Nozzle

gnitaoCtnegAgninaelC

sliOdnaesaerG

stnevloselbulos-retawrostnegretedenilaklA

slohoclasahcus

sniseRsilaklaetuliD

setanobraC/enotsemiLdicacirtinM1

sedixordyhlateM

dicacirtinrociruhplusM1sedinayC

lacigoloibyvaeH

snietorP

dnadicacirtinrociruhplusM1foerutxiM

)detarutas(nispep

serbiF

gnittewtuohtiwrohtiwretawdezirusserP

stnega

lacigoloibthgiLretawdezirusserP

)wolebetoNees(xetaLretawdlocdezirusserP

Mains water

or

Pressurized

cleaning

solution

Transmitter

with autoclean

relay contact

Solenoid

Valve

Pump

Reservoir

(water or

cleaning

solution)

OR

Use a non-

return valve

to maintain

optimum

performance

2.4 Jetwash System – Figs 2.6 to 2.8

Note. Installation must be carried out in accordance

with local water company and council bylaws.

The jetwash system enables automatic cleaning of both the

measuring element and the reference junction by spraying either

water or a cleaning solution at them in situ, thus reducing system

maintenance requirements.

An external pump or solenoid valve is required, controlled by a

pH analyzer with auto-cleaning control functions.

Note. For optimal performance, the pressure of the

jetwash system should be 2 to 3 bar (30 to 45 psi)

greater than the process pressure.

2 MECHANICAL INSTALLATION…

Note. If removed from the process the latex must be

completely removed quickly before it hardens.

Cleaning Solutions

The spray jet tube is available in 316 stainless steel. Some typical

cleaning solutions are:

Loading...

Loading...