13

4 CALIBRATION

4.1 Method

When the electrode system has been correctly connected and

all electrical connections made to the associated pH analyzer,

the system is ready for calibration by immersing the sensor

(using suitably sized beakers) either:

a) in a calibration solution (buffer) of known pH value for a

single-point calibration,

or

b) in two separate calibration solutions of known pH values

for a two-point calibration.

For sensors already in use:

1) Remove the electrode from the process or sample.

2) Wash the visible electrode surface with demineralised

water.

3) Proceed as described in the paragraph above.

To have agreement with a measured sample, there may be times

when a process calibration is necessary.

1) Perform a buffer calibration.

2) Ensure that the electrode is returned to the process for at

least 10 minutes before performing a process

calibration.

3) To mimimize solution temperature effects, measure the

sample at the same temperature as the process.

Refer to the instruction manual for the pH analyzer for full details

of the calibration procedures.

Warning. Close all isolating valves before removing an

electrode from a flow line.

°C0 01025203040506070809

Hp

4 00.400.400.410.410.430.450.480.421.461.412.4

7 11.760.710.700.789.679.679.679.699.630.780.7

9 84.953.932.981.931.950.989.839.809.888.848.8

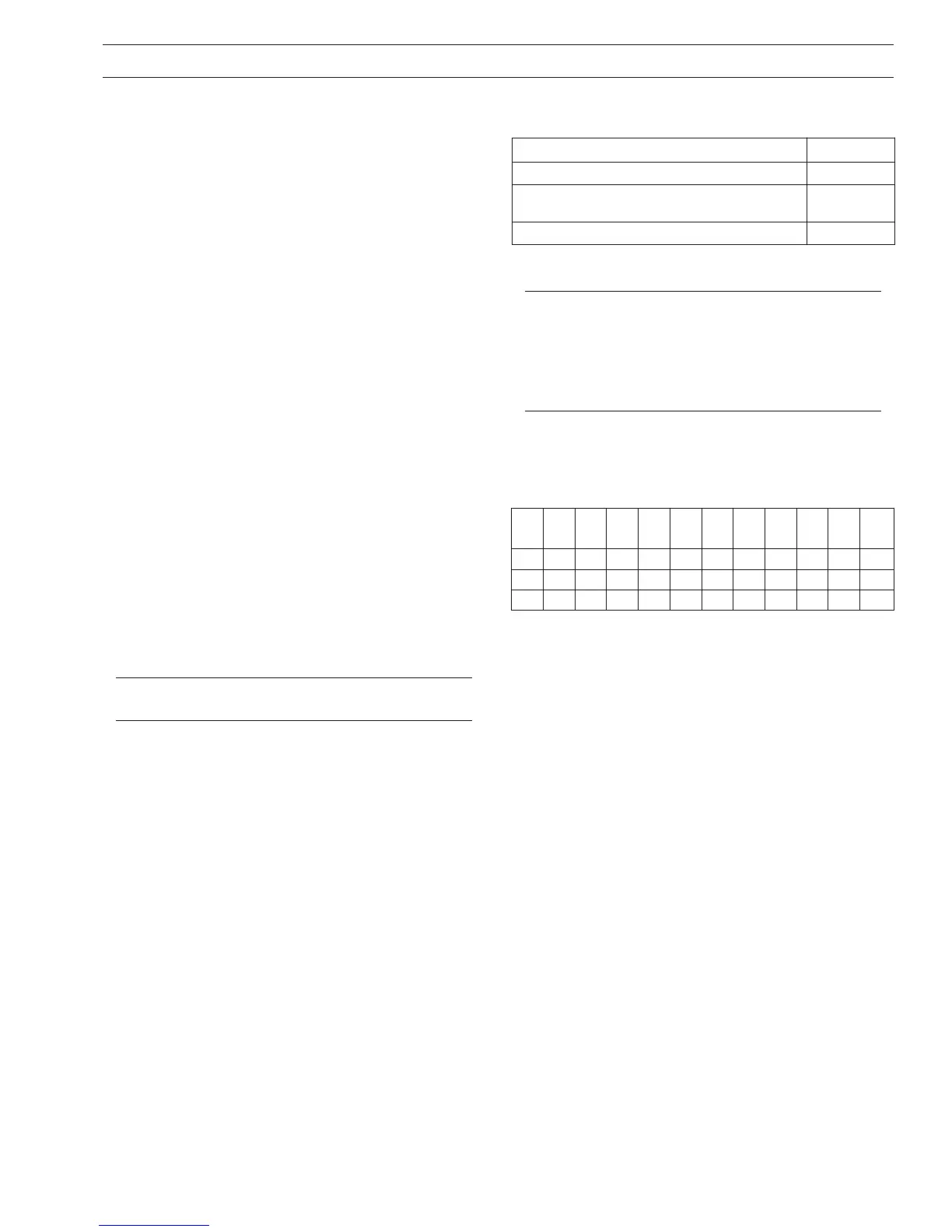

Table 4.1 Recommended Buffer Solutions

4.3 Redox (ORP Sensor)

When the sensor has been correctly connected and all electrical

connections have been made to the associated Redox (ORP)

analyzer, it is ready for calibrating. Follow the calibration

procedure in the analyzer User Guide.

For sensors that are connected to analyzers that do not have

Redox (ORP) sensor calibration capabilities, it is possible to

check the response as follows:

1) Prepare standard 4 and 7 pH buffer solutions. Add one

gramme (heaped spatula) of analar quinhydrone to

100 ml (3.5 Flu oz.) of each buffer solution. Let them

stand for 30 minutes.

2) Immerse the sensor in each solution in turn and note the

mV value when stable.

The values obtained should be within ±15 mV of the following:

pH Buffer mV

4 +259

7 +82

noituloSreffuB.oNtraP

etalahthpnegordyhmuissatopM50.0Hp40110040

muissatoponom/etahpsohpnegordyhmuidosiDHp7

ximetahpsohpnegordyhid

0210040

xarobM50.0Hp90310040

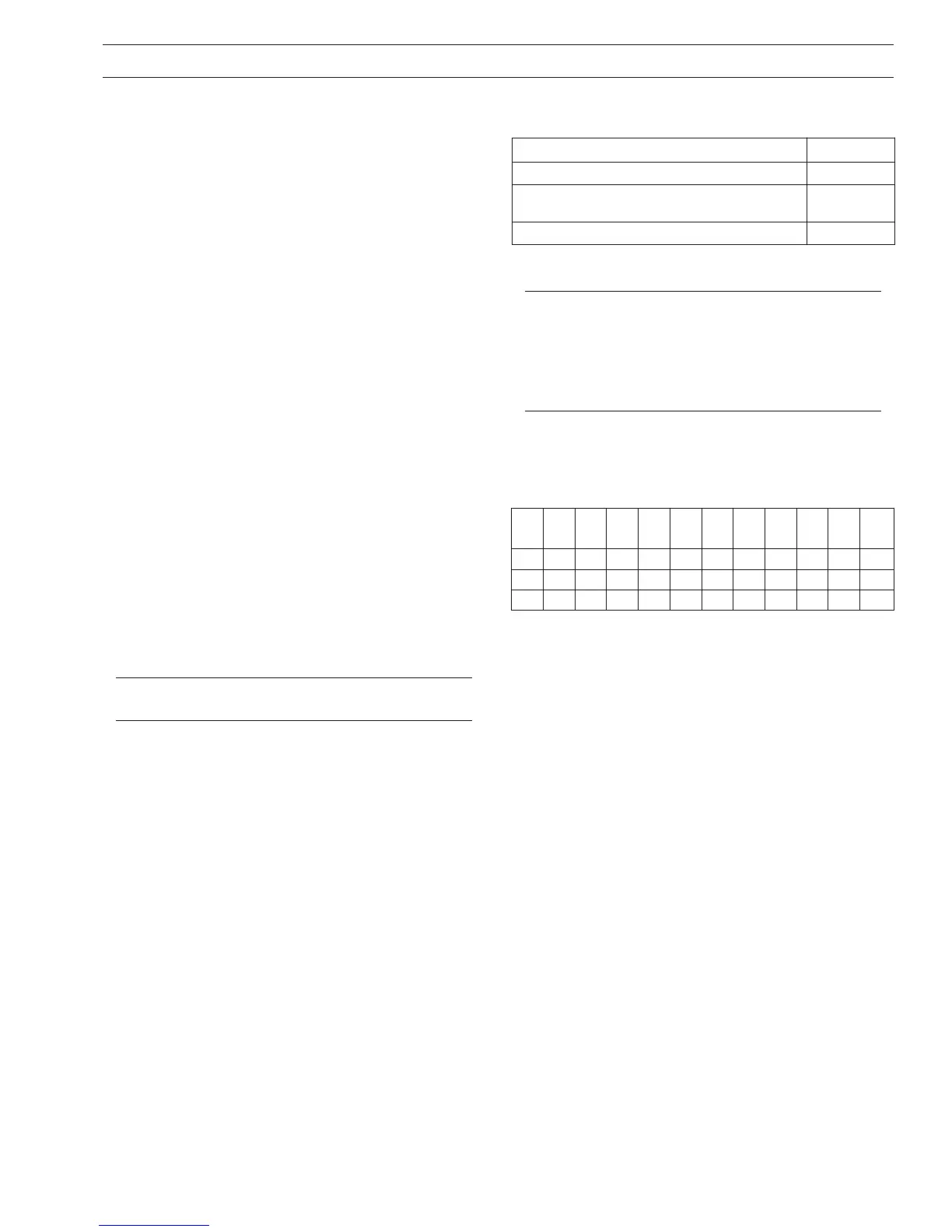

Table 4.2 Buffer pH Value / Temperature (°C)

4.2 Buffer Solutions

Recommended buffer solutions are shown in Table 4.1.

Notes.

• Ensure that the visible surface of the electrode has

been cleaned using demineralized water.

• When moving from one buffer solution to the next,

wash the electrode using demineralized water and

dry it carefully using a soft tissue.

Table 4.2 shows the change in pH value that occurs with a

change in the temperature of the recommended 4, 7, and 9 pH

buffer solutions.

Loading...

Loading...