21 2TLC172001M0211_A

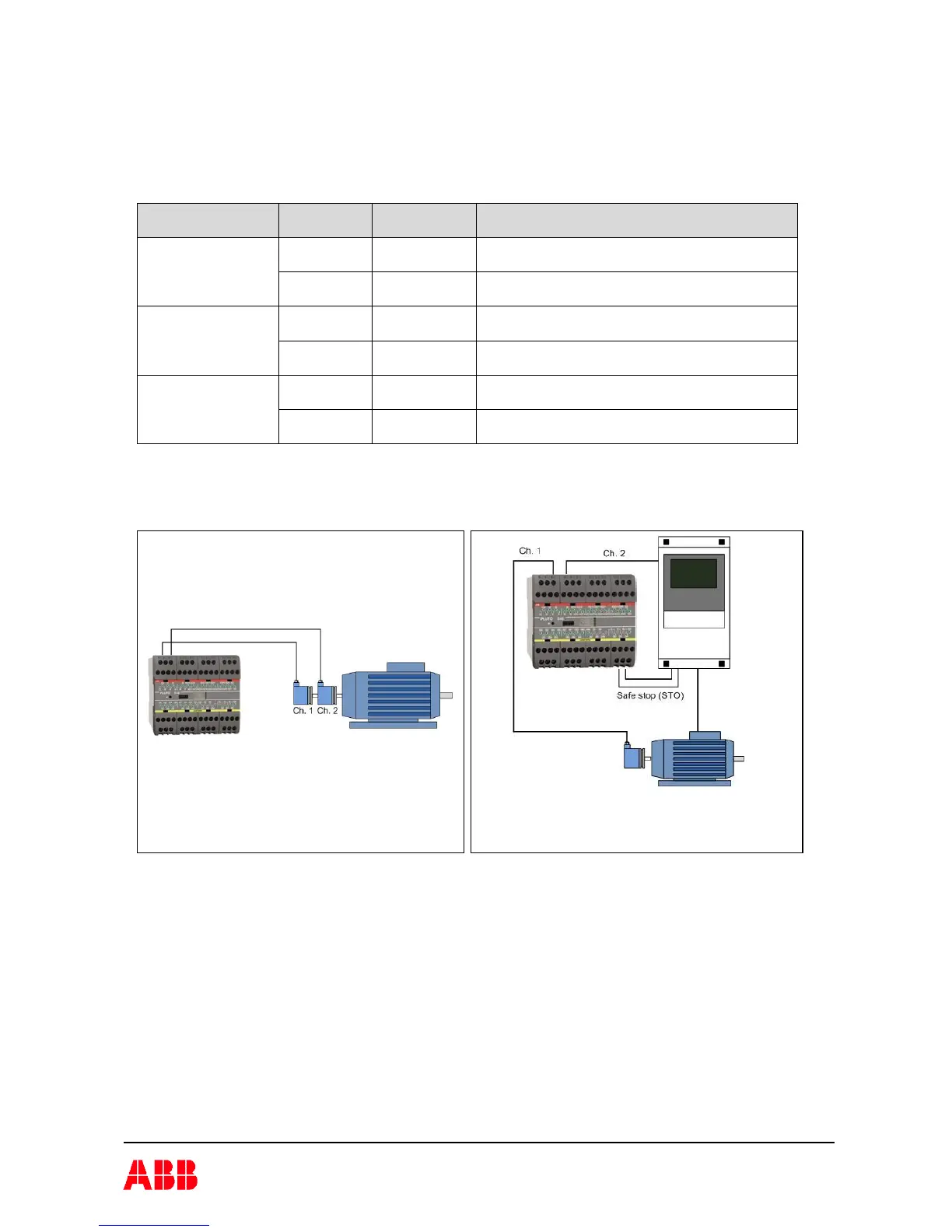

Example with two incremental encoders.

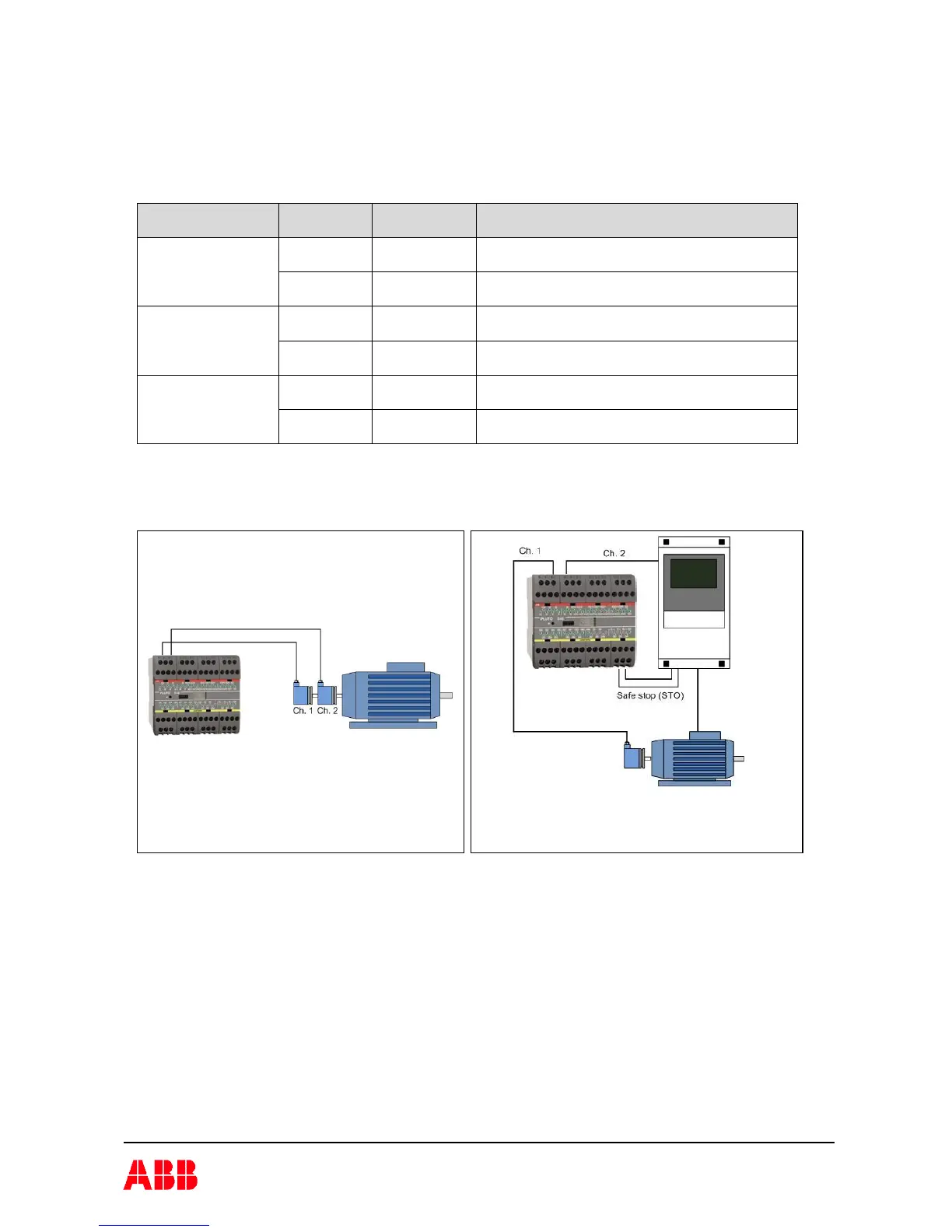

Example of two channel solution with one

encoder and a second channel from a

4.4.7 Possible architectures, achievable safety levels and prerequisites

This table is an overview of safety levels for different applications.

The achievable Cat / SIL / PL depends on the sensor which is used in the application and the

detection capability of faults listed in IEC 61800-5-2, table D.16.

realized in the application program

1 sensor/encoder Overspeed Cat 2 / PL c

SIL 1

Monitoring of dynamic behavior.

(E.g. Stand still is off at expected movement)

Stand still

monitoring

Cat 2 / PL c

SIL 1

Monitoring of dynamic behavior. Stand still

should not last in more than approx. 1 hour

2 sensors/encoders

homogeneous

redundant

Overspeed Cat 3 / PL d

SIL 3

Monitoring of dynamic behavior.

(E.g. Stand still is off at expected movement)

Stand still

monitoring

Cat 3 / PL d

SIL 2

Monitoring of dynamic behavior. Stand still

should not last in more than approx. 1 hour

2 sensors/encoders

diverse redundant

Overspeed Cat 4 / PL e

SIL 3

Monitoring of dynamic behavior.

(E.g. Stand still is off at expected movement)

Stand still

monitoring

Cat 3 / PL d

SIL 2

Monitoring of dynamic behavior. Stand still

should not last in more than approx. 1 hour

4.4.7.1 Application examples

Loading...

Loading...