Operation Manual / TPL65-A10 / -A30

5 Maintenance / 5.4 Cleaning turbine blades and nozzle ring in opera-

tion

© Copyright 2020 . All rights reserved. HZTL2482_EN Rev.E March 2020

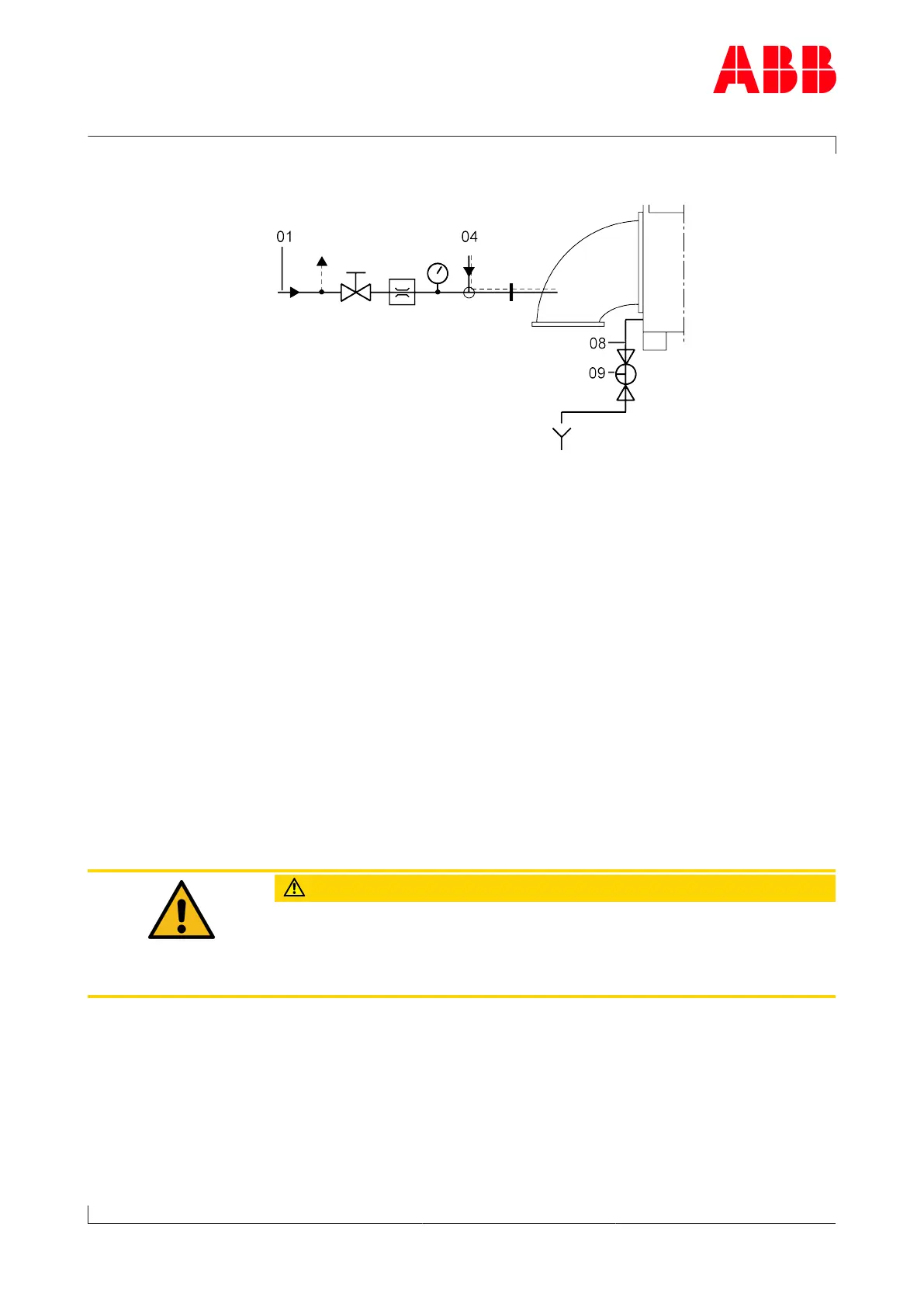

Layout of cleaning pipes

Wet cleaning procedure for turbine during operation

u Meet prerequisites and operating state requirements without fail be-

fore cleaning!

u Make sure water supply (01) is connected, turned on and guaranteed.

u Open drain pipe (08, 09), if provided.

u Switch over 3-way valve (04) from scavenging air mode to water sup-

ply.

u Set the required volume of water on the flowmeter as shown in the

table (see table Cleaning parameters).

u Shut off the water supply again by switching the 3-way valve (04) to

scavenging air mode after injecting the required volume of water.

u The injection process has been completed.

u Close drain hole (if provided) above drain pipe (08, 09).

u After cleaning, wait with engine running for at least 10 minutes

without changing load to allow turbocharger to dry.

CAUTION

Corrosion damage to bearing casing

In order to avoid corrosion damage to the bearing casing, it is advisable

to carry out an additional 30 minutes of operation with TTE > 500°C

after the 10 minute drying time.

Page 59 / 117

Loading...

Loading...