EN • 18

ENGLISHFRANCAISNEDERLANDSESpAñoLITALIANoDEuTSCH

664Y0200.C

• Measure the speed of the impeller that is mounted on the motor

shaft. Adjust the speed of the fan according to the parameters

(Start, Min., Max.) listed in the table of setting parameters on

Page 17 by turning the potentiometer screw (counter-clockwise

to reduce the fan speed and clockwise to increase it).

Fan speed for burner BG 2000-MV :

If the fan of a BG 2000-MV burner is replaced, the fan's speed

is controlled directly by the PWM connector which connects the

fan to the p.c.b.

The potentiometers on the p.c.b. (Start, Min. and

Max.) must be adjusted by an engineer approved by

ACV.

A

fig. 15

1

2

3

4

fig. 16

BuRNER CHARACTERISTICS

BURNER DISMANTLING PROCEDURE

Forsafetyreasonsitisessentialthatyouisolatethe

powersupplyandthegassupplyvalvebeforecarrying

outanyworkontheburner.

Dismantlingtheburner

1. Remove the burner cover.

2. Disconnect the gas connector and the electrical plugs of the

burner.

3. Disconnect the air supply pipe from the venturi.

4. Take off the burner chamber plate by undoing the two

retaining nuts.

Burnerre-assembly

The burner is re-assembled in the reverse order of dismantling

(Step 4 to Step 1).

SETTING PROCEDURE IN THE EVENT OF FAN

REPLACEMENT

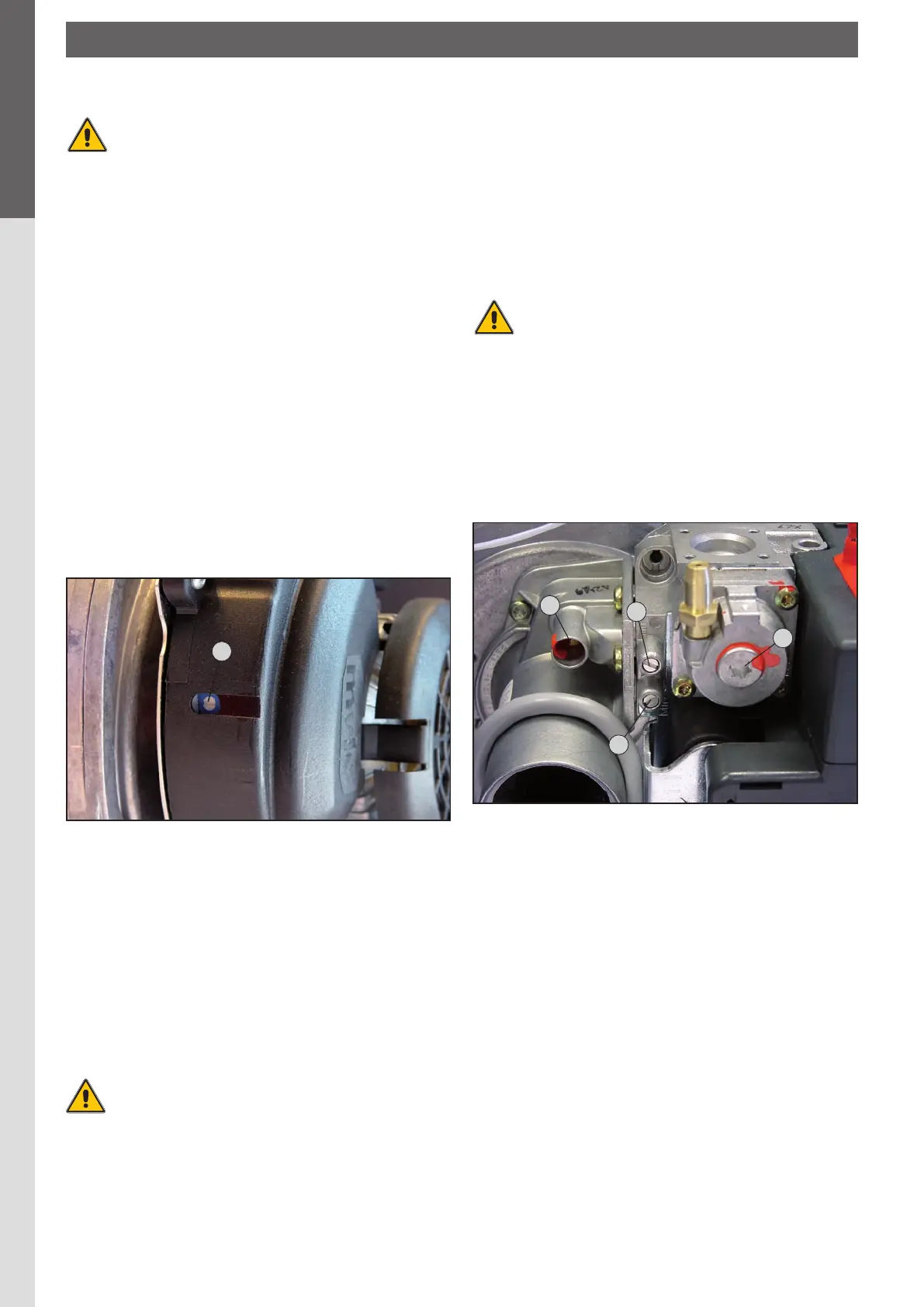

Fan speed for burner BG 2000-SV : (fig. 15)

• Remove the green plug on the front of the fan to gain access

to the adjuster screw on the potentiometer (A).

PROCEDURE FOR ADJUSTING OR REPLACING

THE % OF CO

2

• Measure the burner combustion with an electronic flue gas

analyser.

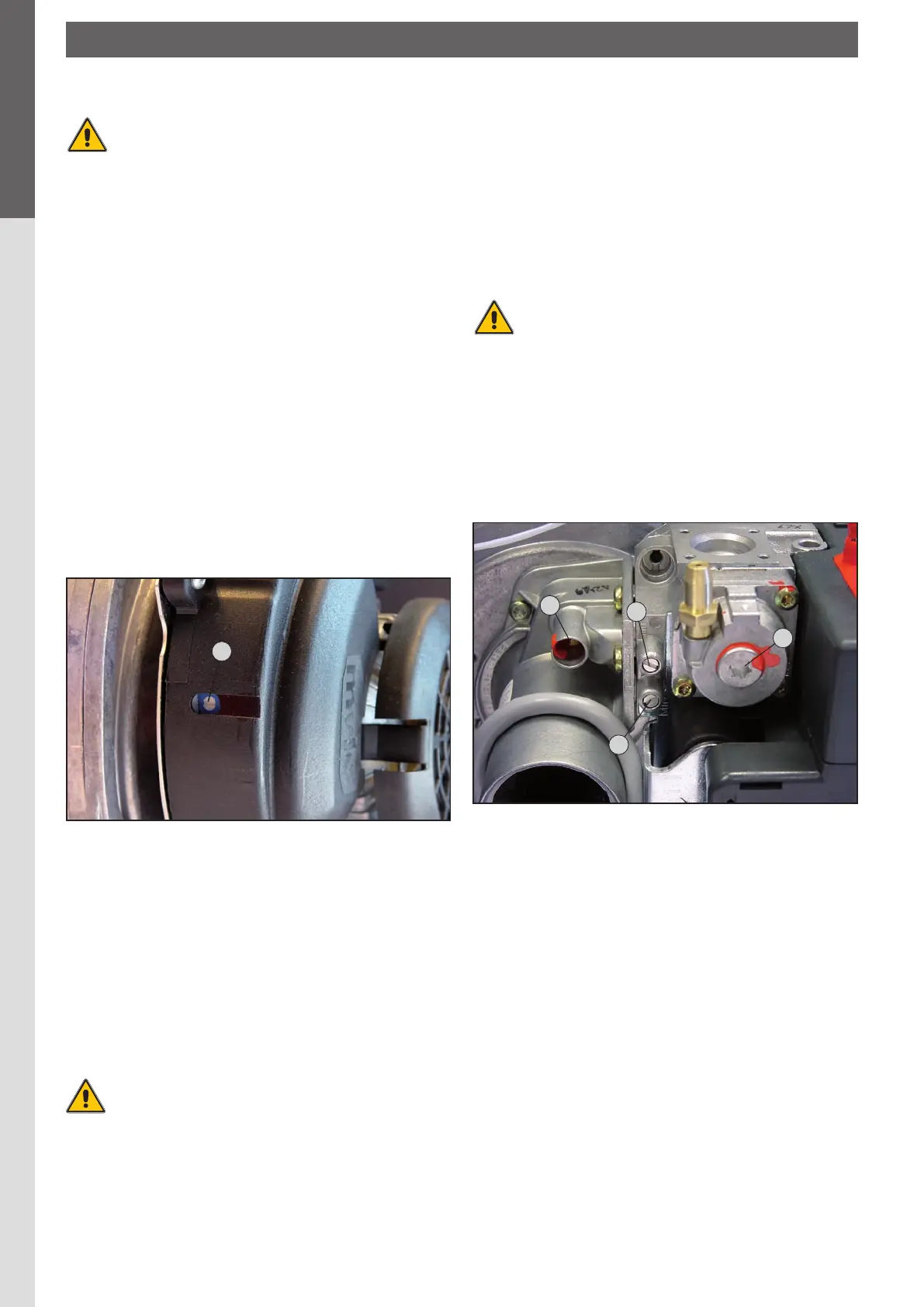

• Adjust the % of CO

2 to the figure shown in the table of setting

parameters on Page 17 by turning the gas flow adjuster screw

on the gas valve. (Fig. 16)

Turncounter-clockwise(moregas) ➠ increasesthe%ofCO

2.

Turnclockwise(lessgas) ➠ reducesthe%ofCO2.

The offset (4) is set at the factory and requires no

adjustment. Nevertheless ACV recommends that

youcheckthis setting. (Refer tothetable of setting

parameters).

You should contact your installer should you findany

significantdeviation.

1. Gas flow adjuster screw

2. Offset pressure measuring point

3. Upstream gas pressure measuring point

4. Offset adjuster screw cover

ELECTRODE DISTANCE AND GAP

BG 2000-S/SV

• Distance between ionisation electrode and tube :

A=10to15mm (refer to fig. 17)

• Distance between ignition electrode and tube :

B=2to5mm

(refer to fig. 18)

BG 2000-M/MV

• Distance between ionisation electrode and tube :

C=10to15mm (refer to fig. 19)

• Distance between ignition electrode and tube :

D=4to7mm (refer to fig. 20)

• Ignition electrode gap :

E=2to5mm

(BG 2000 M-MV : refer to fig. 21)

Loading...

Loading...