6

AGD 650

DUAL ZONE STOP-LINE DETECTOR

AGD 650

DUAL ZONE STOP-LINE DETECTOR

AGD 650

DUAL ZONE STOP-LINE DETECTOR

AGD 650

DUAL ZONE STOP-LINE DETECTOR

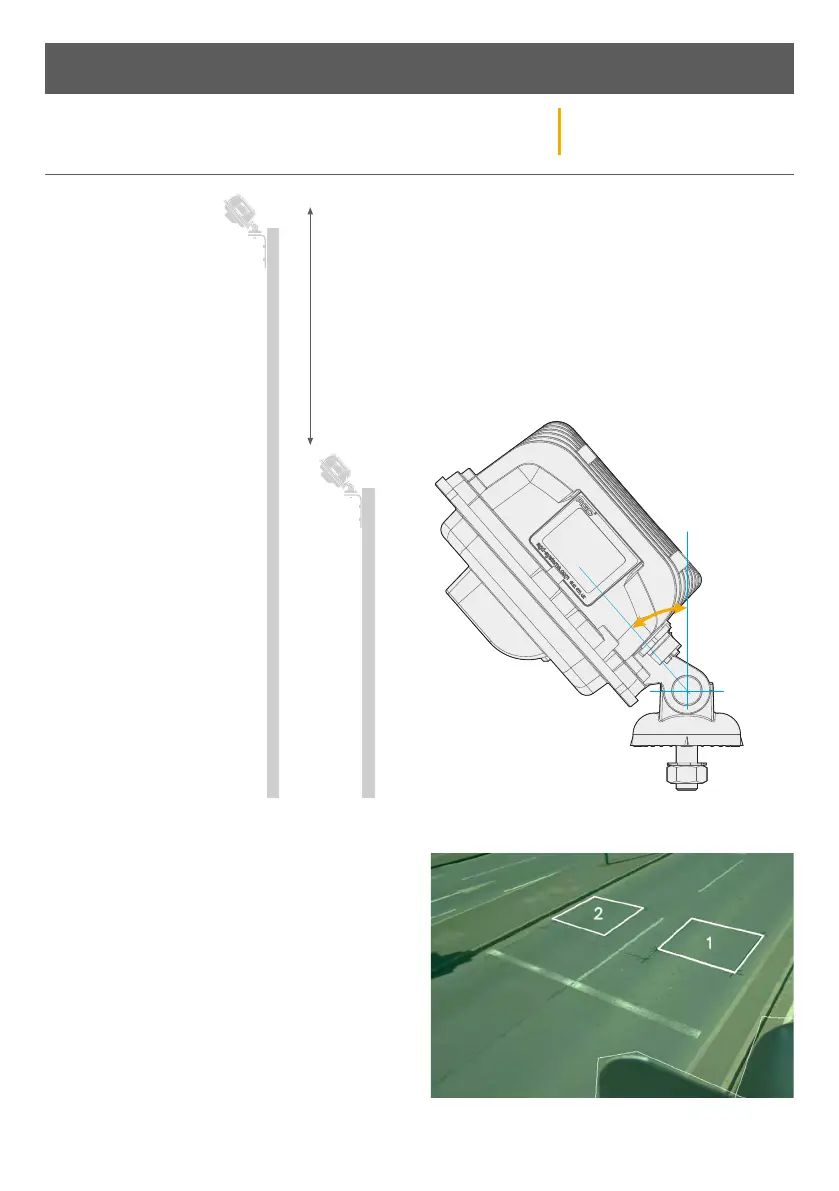

Max 6m

Min 3m

Variable

adjustment

to suite all

applications

PHYSICAL INSTALLATION

STEP 1 - MOUNTING

HEIGHT – The AGD 650

Dual Zone Stop-line

Detector has excellent

performance when

mounted between heights

of 3-6 metres.

If you have an application

whereby you wish to

mount the detector outside

of these heights, then

please contact AGD.

STEP 2 - DETECTOR ALIGNMENT – The AGD650 Dual

Zone Stop-line Detector should be mounted using the

supplied hardware. The optimal mounting angle will

change depending on the installation location; aiming

the camera to the centre of the area of interest is a

good start position. The mounting angle may need

to be corrected during commissioning stage of the

installation. Ensure the detector is securely fixed and

the mounting nut is tight.

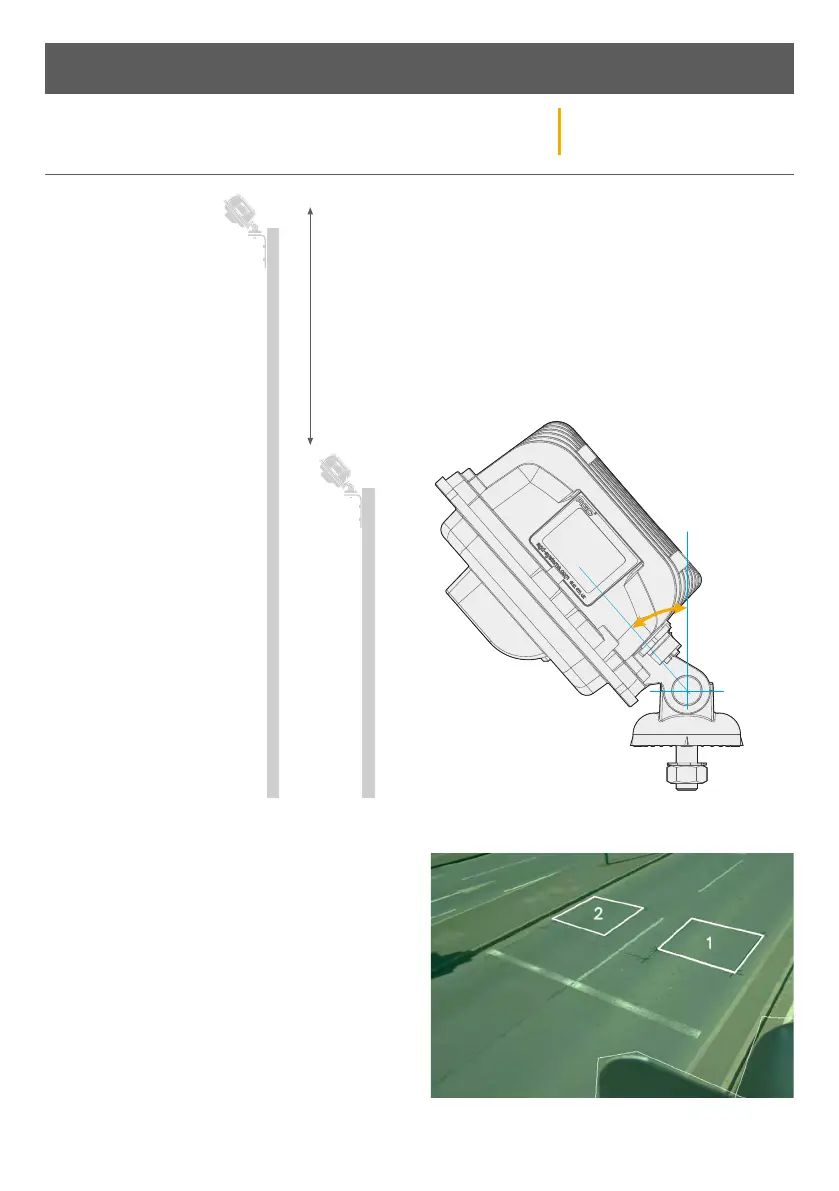

STEP 3 - FINAL ADJUSTMENT & VERIFICATION

Confirm the detector is correctly aligned, the entire

stop-line should be visible when looking at the

detectors view within the GUI. Where possible, the

field of view should include at least one full vehicle

length before and aer each detection zone. The

horizon should be out of view to reduce sun glare.

Once complete, please monitor traic to ensure zones

are correctly placed.

Installation and Commissioning

Loading...

Loading...