85

Order online at www.agilent.com/chem/store

Detectors

Flame Ignition

If the flame goes out or will not light:

• Measure the hydrogen/air and makeup flow rates – Low H

2

or makeup flows indicated

a plugged jet, or a leak at the column fitting. Measure each gas flow independently.

• Confirm that the igniter is glowing during the FID ignition sequence.

• Check for partially or completely plugged jet – Formation of silica or carbon deposits

at the tip of the jet can cause plugging. Incorrect capillary column installation can also

cause plugging.

It is best to replace a plugged jet, rather than try to clean it.

•

Check that the capillary column is not installed all the way to the jet tip

(withdraw 1-2 mm).

• Check that the correct type of jet is installed for the column you are using.

• Check for leaking column or adapter fitting at the base of the FID.

• Check the lit offset value to make sure it is not too low or too high. Adjust the value

(normally set to 2.0 pA).

Injecting large volumes of aromatic solvent or water can cause the flame to go out.

Switch to a non-aromatic solvent or reduce injection volume.

Increased FID Noise or Loss in Sensitivity

FID noise is affected by:

• The cleanliness of the GC gases and gas delivery system – Ensure that the carrier/H2

and air purity is ≥ 99.9995%. Check traps and filters in the gas supply lines. The FID

background signal should be ≤ 20 pA when the flame is lit and stablized.

• Dirty collector/PTFE insulators – Clean or replace.

• Dirty jet – An incorrect flame pattern can increase noise or affect sensitivity.

Tips & Tools

For optimal sensitivity, use

Agilent gas purifiers to ensure

cleanliness of your GC gases.

See page 4.

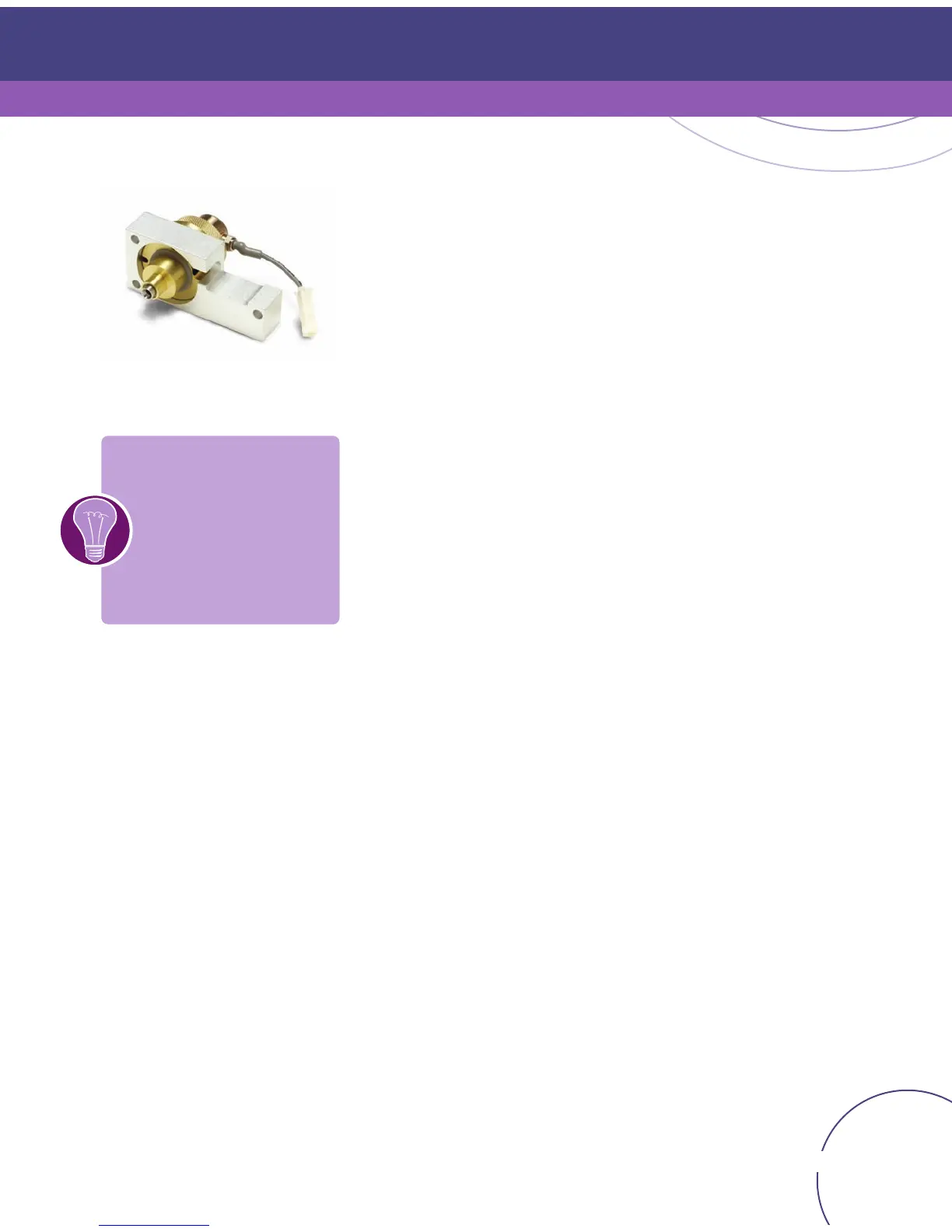

FID collector assembly

Loading...

Loading...