4

Order online at www

.agilent.com/chem/store

Contaminants & Purities

Contaminants in gases are major contributors to capillary column degradation

and detector noise, and can interfere with chromatographic results. Concentration

of these contaminants vary by the grade of gas.

Hydrocarbons and Halocarbons

• Decrease detector sensitivity by increasing detector background noise.

• Can also cause baseline drift or wander, contaminant peaks, and noisy

or high offsets of baselines.

Moisture

• Can be introduced by improper handling and/or installation of plumbing.

• A common cause of column stationary phase degradation.

• Can damage instrument.

Oxygen

• Most common contaminant.

• A common cause of column stationary phase and inlet liner degradation.

• Can cause decomposition of labile analytes.

• Opportunity for introduction at every fitting present in the gas line or during

use of gas permeable tubing.

Tips & Tools

Gas purifiers should always be

oriented vertically

, not horizontally

.

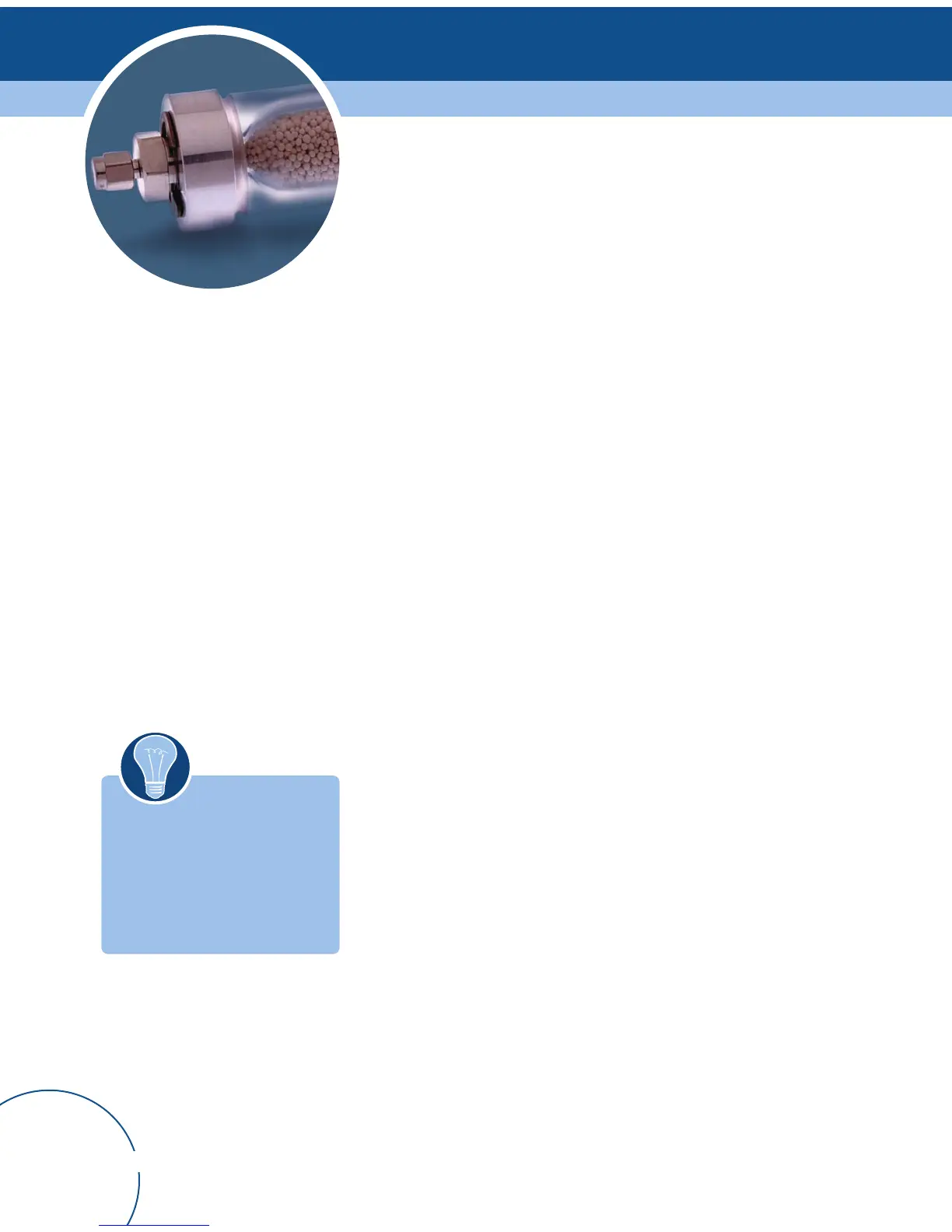

Purifiers are available in a variety of sizes and configurations to remove common

contaminants like oxygen, moisture, and hydrocarbons. In-line gas purifiers, including

refillable, indicating, S-shaped, and metal body types, are made to remove specific

contaminants. Agilent also offers gas purification systems with removable cartridges.

These systems provide the ability to design the right combination of filters needed

for your application to achieve the proper gas purity.

Gas Purification Systems

Loading...

Loading...