5

Order online at www.agilent.com/chem/store

Gas Management

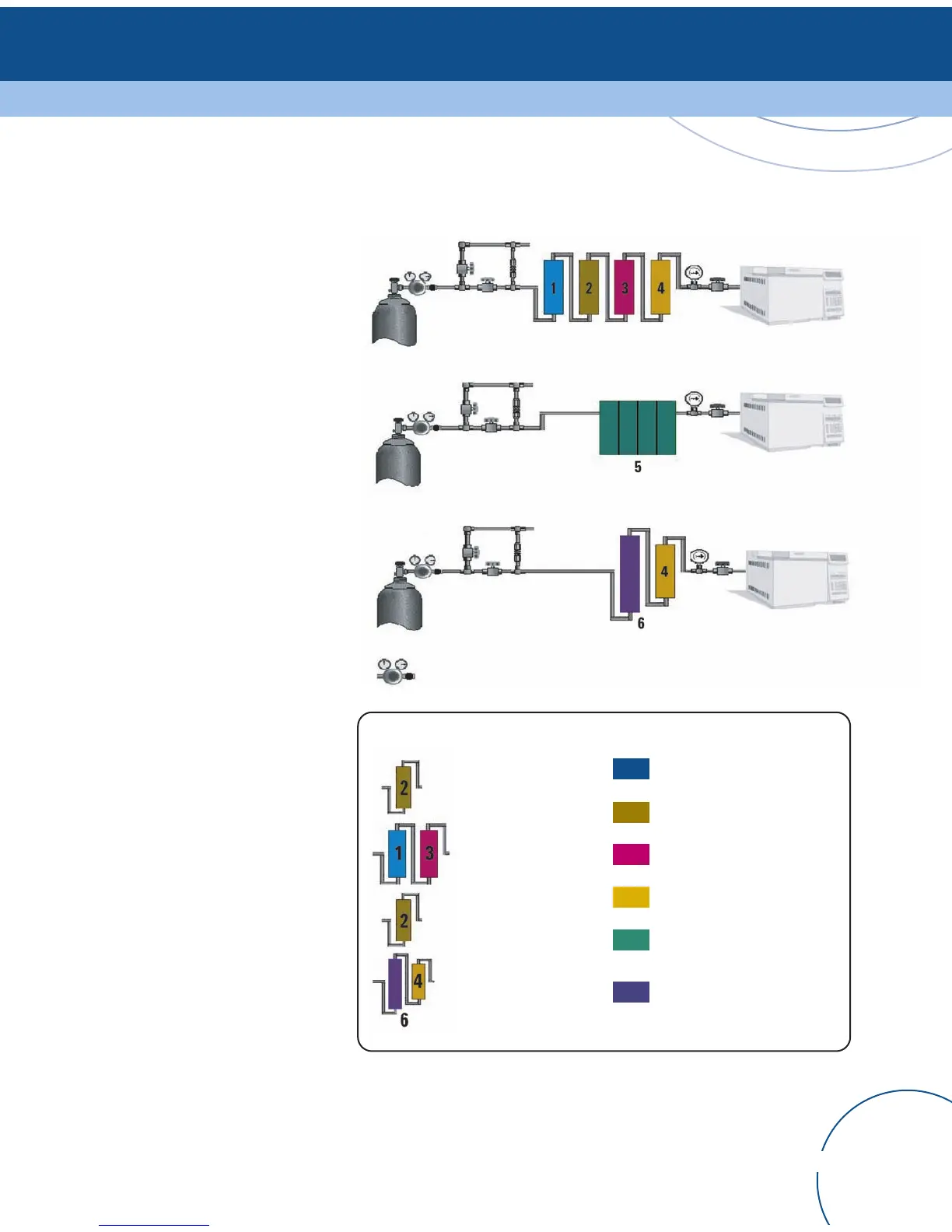

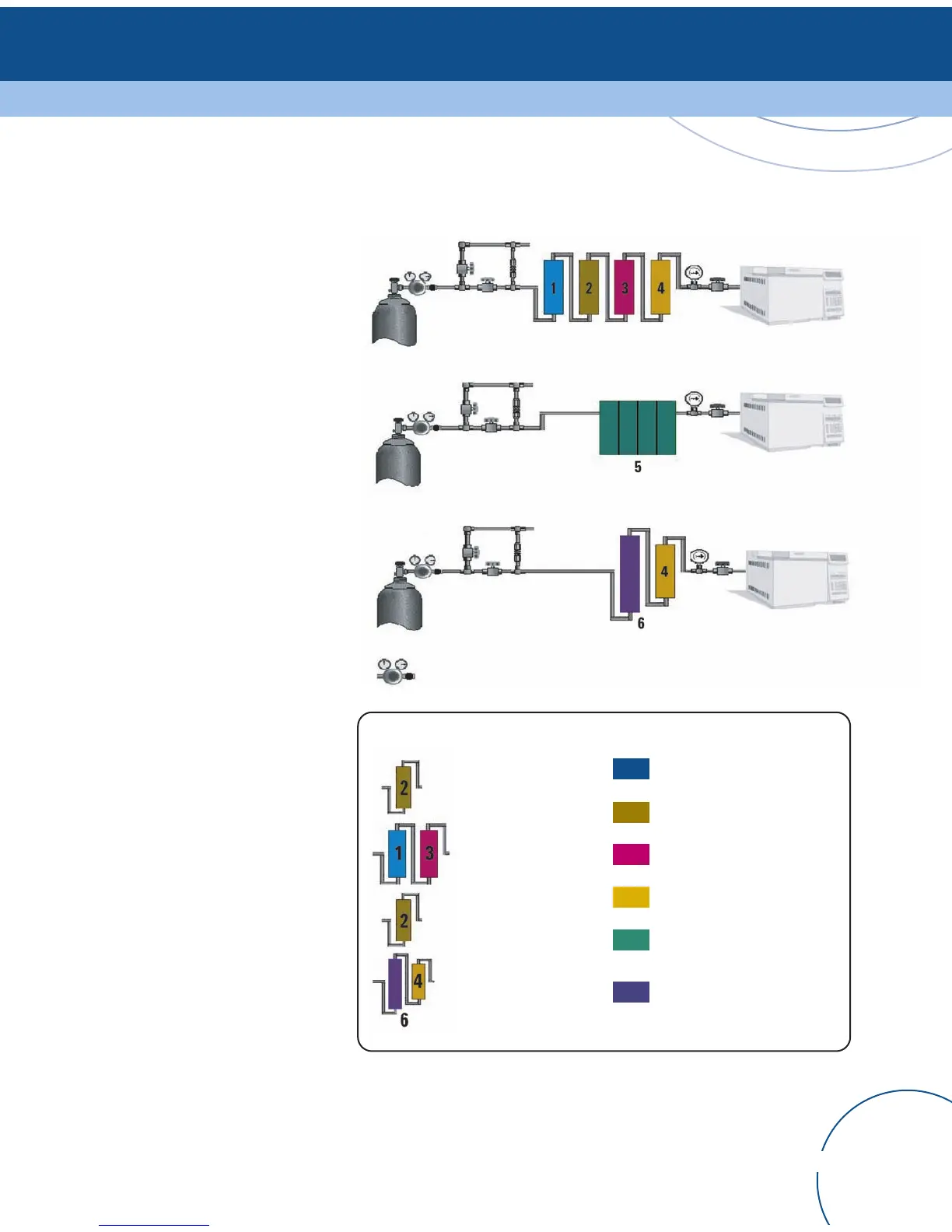

The Carrier Gas Purification illustration

shows the most common gas purification

configurations used in gas chromatography.

Regardless of which purification

system is employed, proper installation

and maintenance is required to

achieve optimal performance from

the purification system(s). A purifier

that is not maintained will eventually

expire and become ineffective, or worse,

a source of contamination.

• Determine desired purity level.

• Keep number of fittings in gas line

to a minimum.

• Install purifiers in a convenient location

close to the GC.

• Purifier log books are useful for

determining maintenance schedule.

• Use indicating traps closest to the GC

so you can determine when to change

the traps that are upstream.

1 = Moisture Trap

2 = Hydrocarbon Trap

3 = Oxygen Trap

4 = Indicating Oxygen T

rap

5 = Gas Purification System

6 = Combination Trap for

moisture, oxygen, and

hydrocarbon removal

Gas supply

Vent

Gas supply = cylinder, in-house line, or gas generator

Regulator = brass dual stage regulator

-OR-

-OR-

In-Line Gas Purifiers

Gas Purification System

Combination Trap

Gas supply

FID make-up, air, and H

2

ECD make-up

ELCD reaction gas

MS carrier gas

KeyDetector Gas Purification

Carrier Gas Purification

Loading...

Loading...