DRAFT

10/9/14

TriScroll 800 Inverter Vacuum Pump

14

Maintenance

General Information

Agilent TriScroll 800 Inverter pump is designed to provide years of trouble-free service if maintenance procedures and

intervals are observed. Bearing grease replenishment and tip seal replacement is recommended when pump base pressure

has risen to an unacceptably high level for your application. Bearings, rotary seals and O-rings should also be replaced if

the pump exhibits humming or grinding noises from the bearings. Main bearing life may be shortened if your application

requires the pumping of high quantities of water vapor. Use of the bearing purge kit (PTSPURGEKIT) mentioned earlier will

keep this water from impacting bearing life.

Maintenance should be performed in accordance with procedures, tooling and materials specified in the manuals listed

below.

Related TriScroll Manuals

Other manuals related to tip seal replacement, pump module replacement, and major maintenance of the TriScroll 800

Inverter pump are listed in Table 10.

Maintenance and Tooling Kits

Material and tooling required to perform maintenance on TriScroll pumps is provided in kit form. A description of each kit

and ordering information is provided in Table 11.

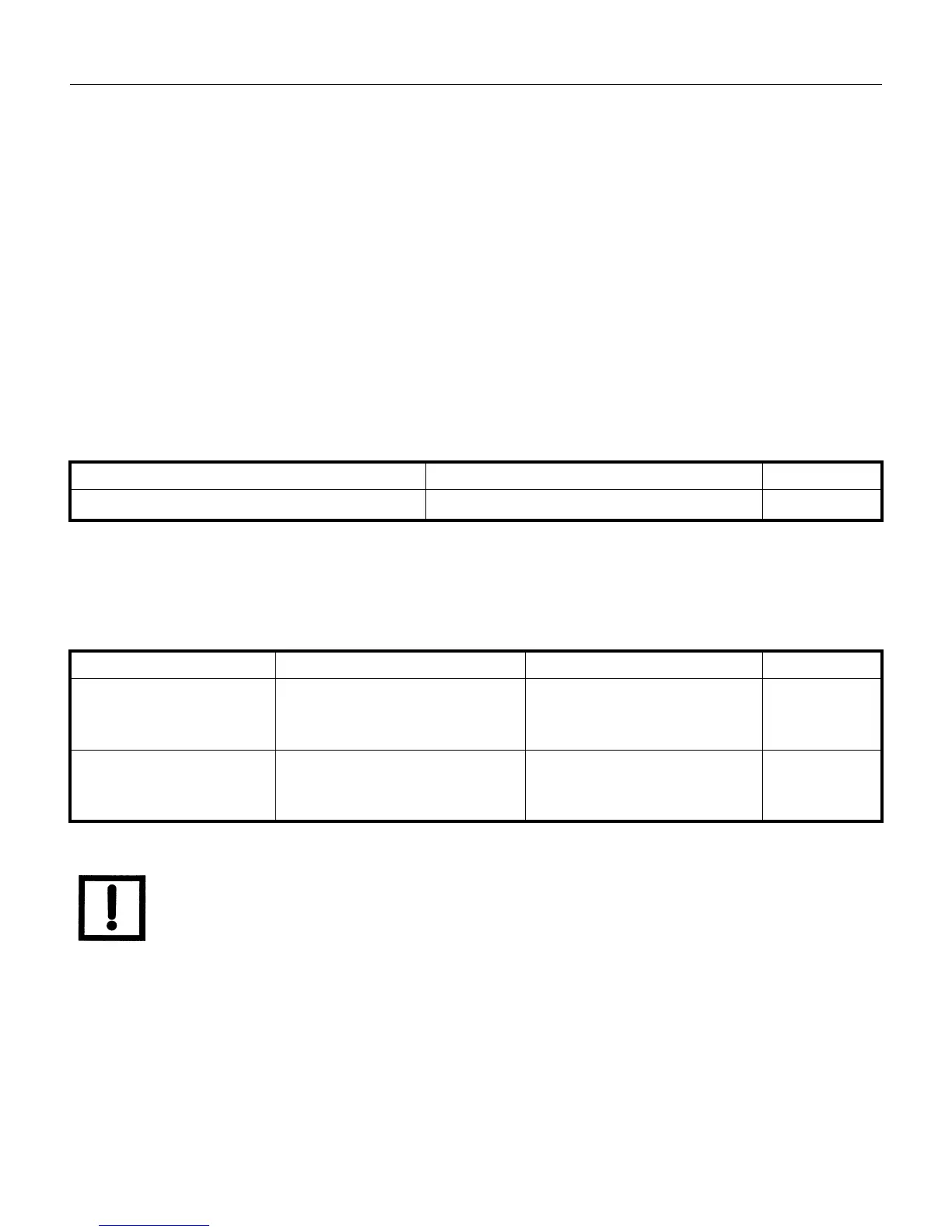

Table 10 Other Related Manuals

Title Applicable TriScroll Model Part Number

Tip Seal Replacement Manual All TriScroll 800 Series models 699904310

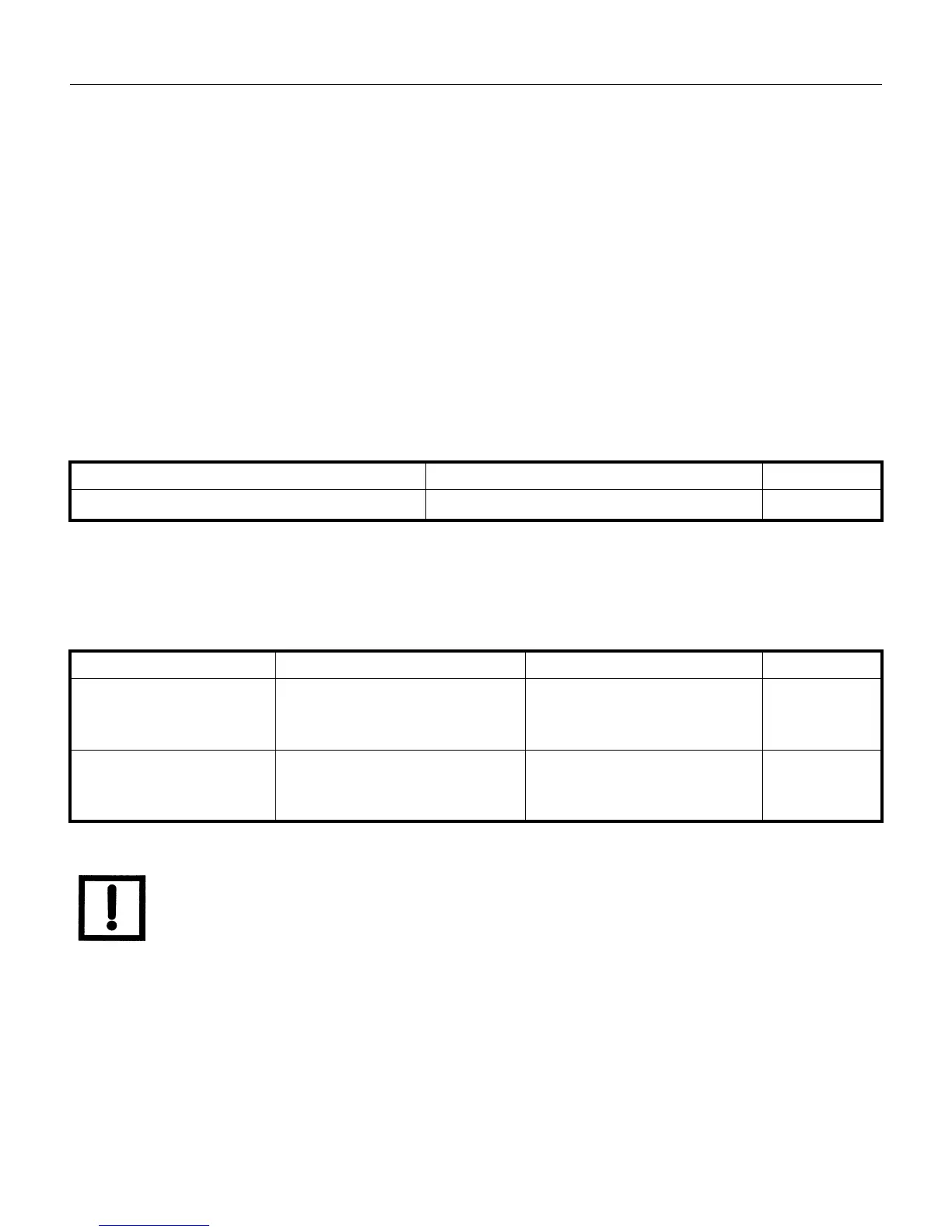

Table 11 Maintenance and Tooling Kits

Description Contents Applicable TriScroll Model Part Number

Tip Seal Tool Kit All tools required to change the tip

seals on the TriScroll 800 Series

pumps.

All TriScroll 800 Series models PTSTSTKIT

Replacement Tip Seal Set Replacement tip seals and static

O-rings for TriScroll 800 Series

pumps.

All TriScroll 800 Series models PTSS0800TS

NOTE After tip seal replacement, the

TriScroll 800 Inverter pump may

require up to 100 hours run time to

achieve full rotational speed.

Loading...

Loading...