16 Instructions for Use

274/342 TwisTorr 74 FS User Manual / 87-901-053-01

Pump Fixing

WARNING!

Failure to comply with these installation instructions could result in the pump

detaching from the system in the event of a rotor failure, which could cause

property damage or serious injury or death.

The TwisTorr 74 FS can be installed in any position. Fix the TwisTorr

74 FS in a stable position, mounting the inlet flange of the turbopump

to the system counter-flange, with a connection capable of

withstanding a torque of 250 Nm around its axis.

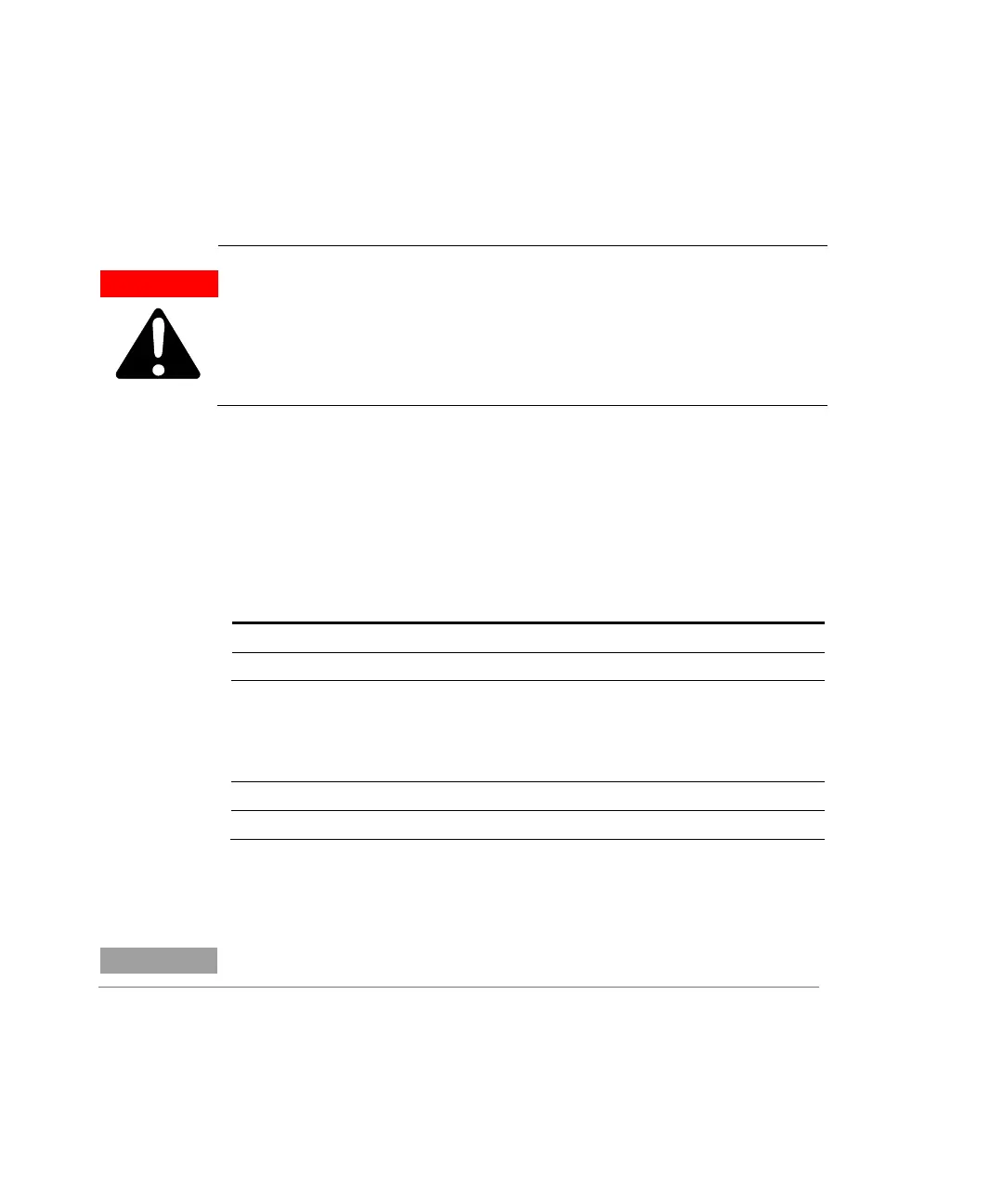

The following table shows, for each flange, the necessary number of

clamps and the relevant fixing torque.

FLANGE FIXING DEVICE N. FIXING TORQUE

ISO 63 K M10 clamps: IC63250DCMZ 4 22 Nm

CFF 4 ½ Mounting Kit X3502-68007

Metric screws X3502-68008

American screws X3502-

68009

8 20 Nm

CFF 2 ¾ Screws 6 20 Nm

KF 40 Clamp KF40 1 -

The turbopump with ConFlat inlet flange must be fixed to the

vacuum chamber by means of the appropriate Agilent hardware. See

the appendix "Technical Information" for a detailed description.

NOTE

The TwisTorr 74 FS cannot be fixed by means of its base.

Loading...

Loading...