30 Power Hoe 6000 Edition 11.98

5. Maintenance

Hoeing drive

The hoeing drive is filled with semi-fluid

grease. Refilling is not necessary, if no

leaks are visible on the housings and their

seals.

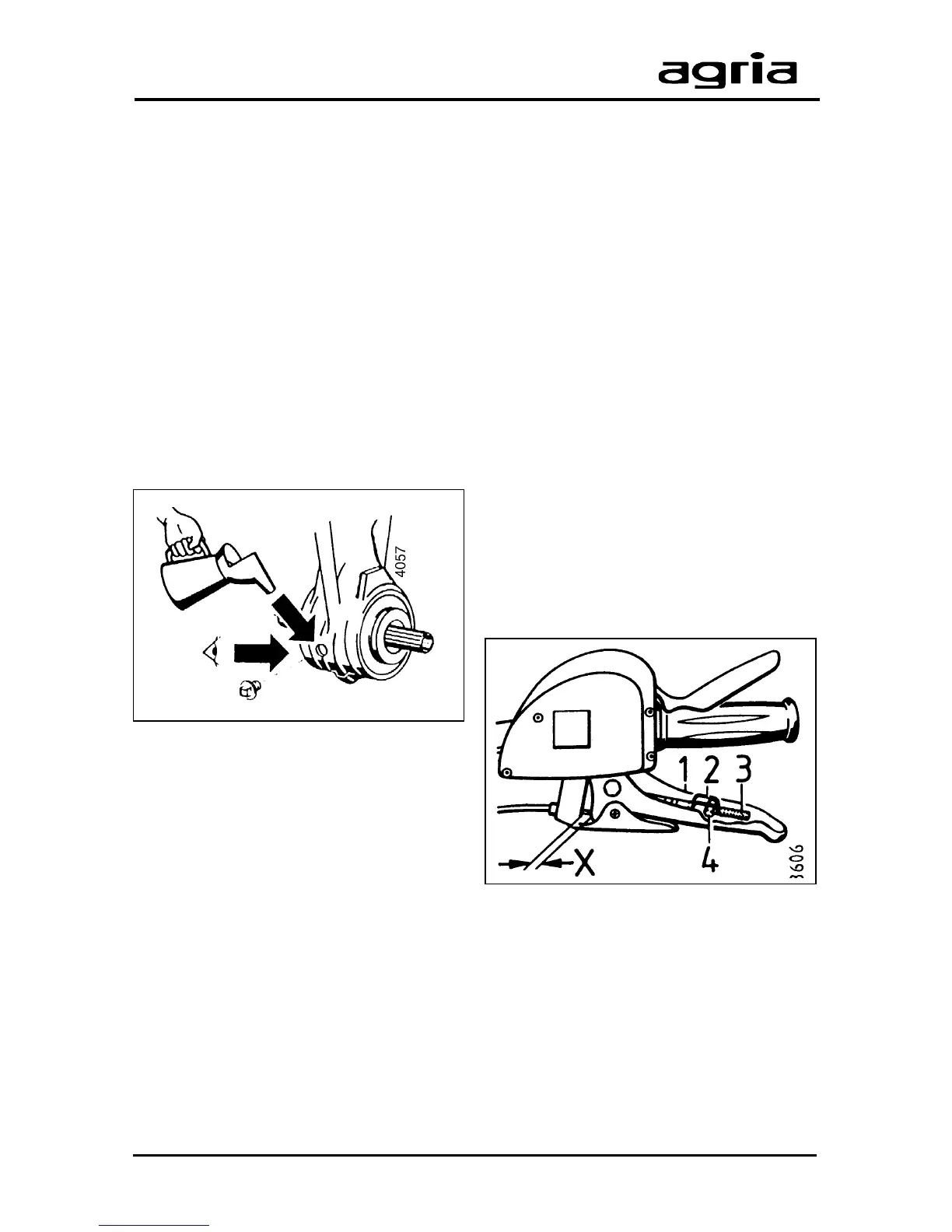

Lubrication inspection

l

Open the plug (A/12)

l

Crank the hoeing shaft at least 6 ro-

tations. Lubrication is fine, if the chains

are wet with transmission oil (visual in-

spection). Top up transmission grease, if

necessary.

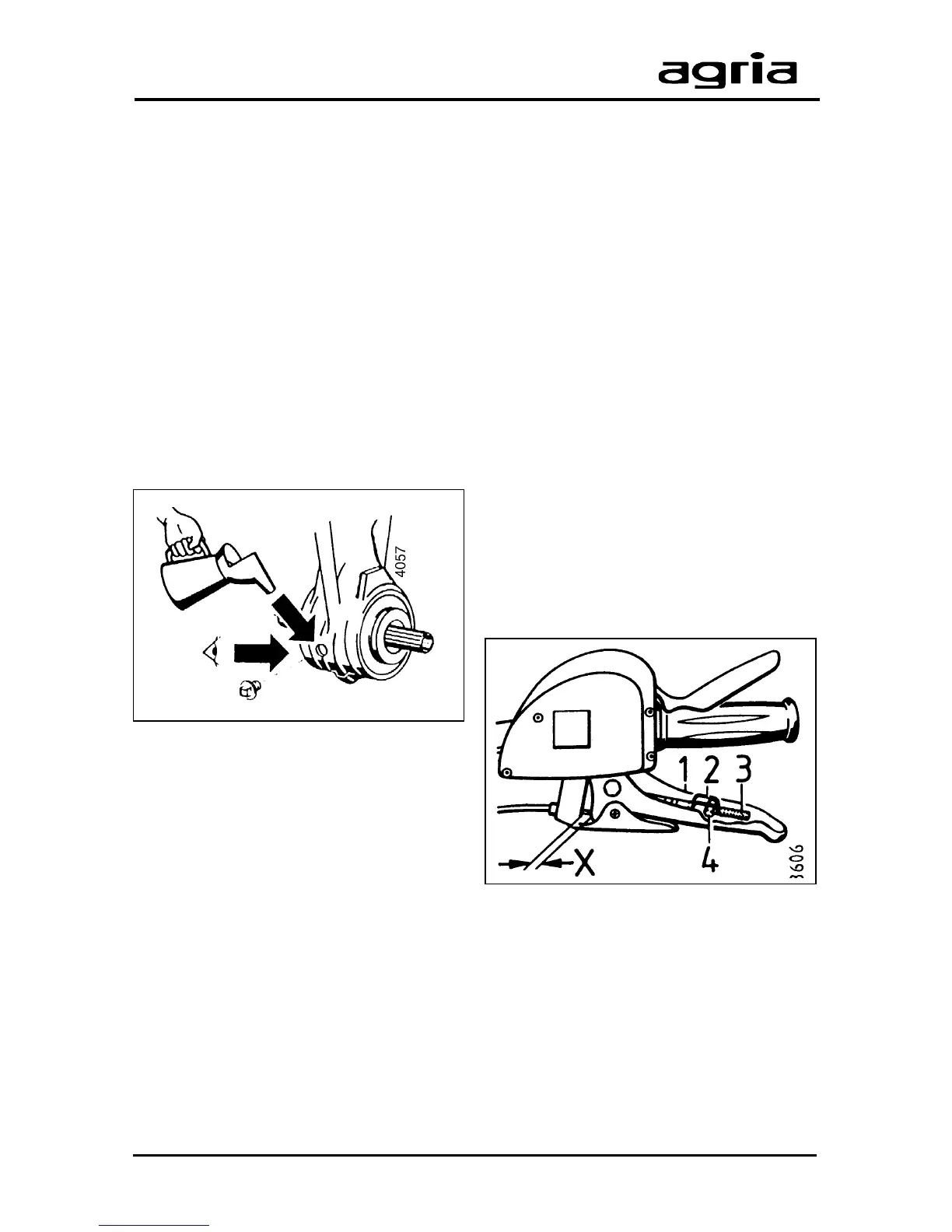

Adjustments on Levers

Check play or settings each time before

you operate the machine and readjust

them, if necessary (in particular during

breaking-in after starting up the machine

and after replacing the clutch disks).

l

Remove retaining spring (2) with a

screw driver or a similar tool.

l

Use set pin (4) to press the cable end

(3) out of the bracket in the lever.

l

Adjust the set pin (4) to a play of X.

(Screw set pin in to reduce the play, screw

it out to increase the play).

l

For inspection, hook the cable end

back into the bracket, using the set pin.

l

Fit retaining spring (2).

Clutch lever:

X = 3–5 mm (Clutch play)

Loading...

Loading...