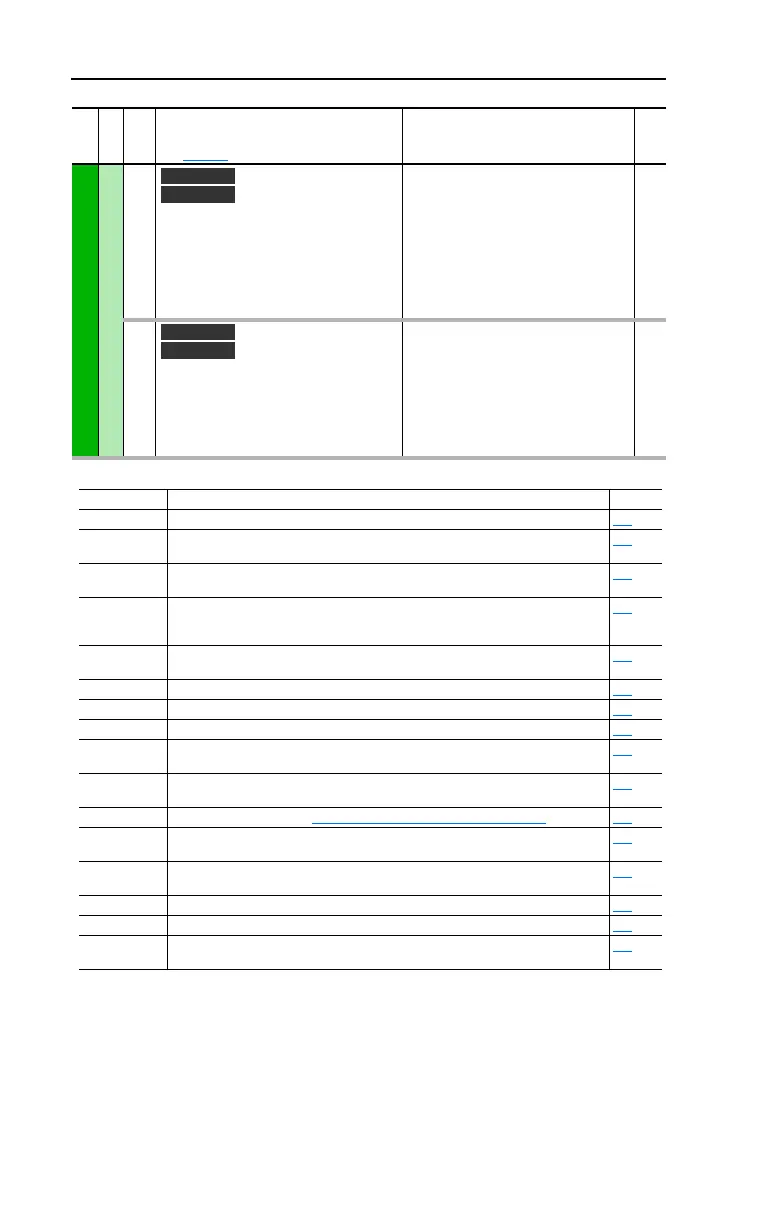

3-56 Programming and Parameters

INPUTS & OUTPUTS

Analog Outputs

354

355

[Anlg Out1 Scale]

[Anlg Out2 Scale]

Sets the high value for the range of

analog out scale. Entering 0.0 will disable

this scale and max scale will be used.

Example: If [Analog Out Sel] =

“Commanded Trq,” a value of 150 =

150% scale in place of the default 800%.

Default:

Min/Max:

Units:

0.0

[Analog Out1 Sel]

0.01

377

378

[Anlg1 Out Setpt]

[Anlg2 Out Setpt]

Sets the analog output value from a

communication device. Example: Set

[Data In Ax] to “377” (value from

communication device). Then set [Analog

Outx Sel] to “Param Cntl.”

Default:

Min/Max:

Units:

20.000 mA, 10.000 Volts

0.000/20.000mA

–/+10.000V

0.001 mA

0.001 Volt

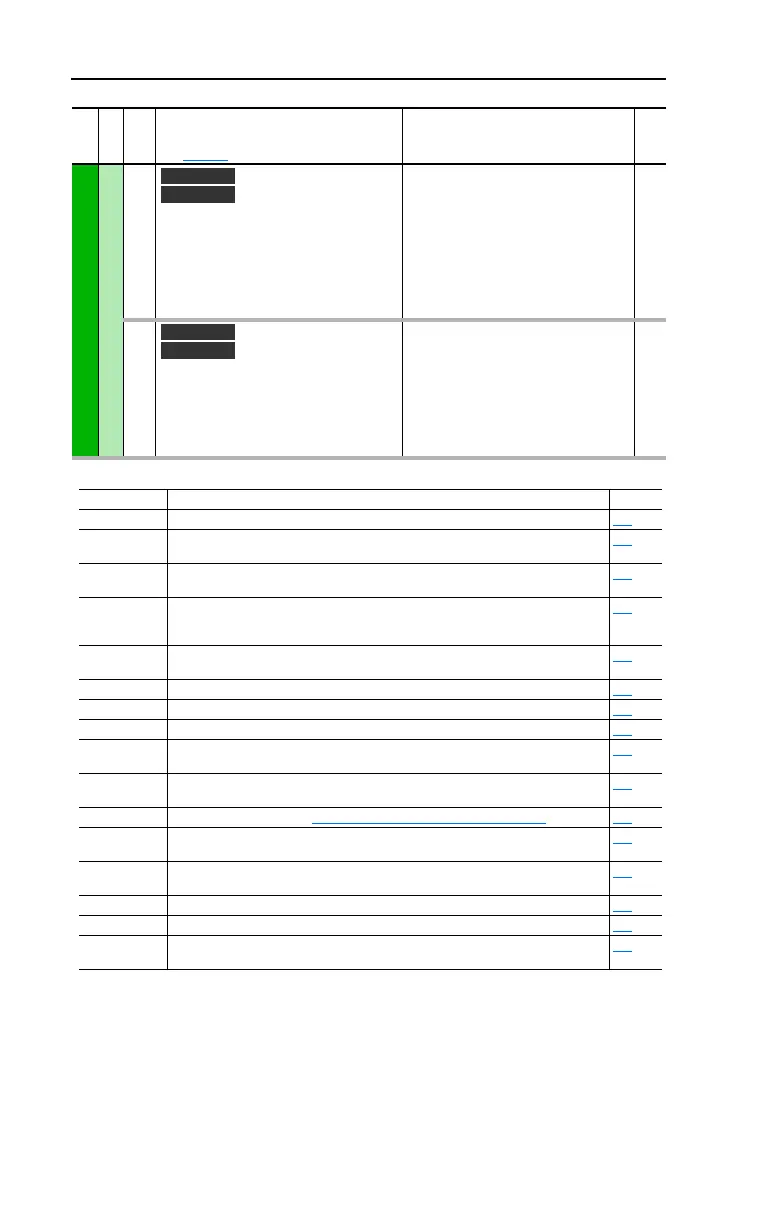

Selected Option Definitions – [Analog Outx Sel], [Digital Inx Sel], [Digital Outx Sel]

File

Group

No.

Parameter Name & Description

See page 3-2 for symbol descriptions

Values

Related

Vector v3

Vector v3

Vector v3

Vector v3

Option Description Related

At Speed Relay changes state when drive has reached commanded speed. 380

Fast Stop When closed, the drive will stop with a 0.1 second decel time. (If Torque Proving is

being used, float will be ignored at end of ramp and the mechanical brake will be set).

361

Excl Link Links digital input to a digital output if the output is set to “Input 1-6 Link.” This does not

need to be selected in the Vector option.

361

Input 1-6 Link When Digital Output 1 is set to one of these (i.e. Input 3 Link) in conjunction with

Digital Input 3 set to “Excl Link,” the Digital Input 3 state (on/off) is echoed in the Digital

Output 1.

380

Micro Pos Micropostion input. When closed, the command frequency is set to a percentage

speed reference as defined in [MicroPos Scale%], parameter 611.

361

MOP Dec Decrements speed reference as long as input is closed. 361

MOP Inc Increments speed reference as long as input is closed. 361

MtrTrqCurRef Torque producing current reference. 342

Param Cntl Parameter controlled analog output allows PLC to control analog outputs through data

links. Set in [AnlgX Out Setpt], parameters 377-378.

342

Param Cntl Parameter controlled digital output allows PLC to control digital outputs through data

links. Set in [Dig Out Setpt], parameter 379.

380

PI Reference Reference for PI block (see Process PI for Standard Control on page C-13). 342

Precharge En Forces drive into precharge state. Typically controlled by auxiliary contact on the

disconnect at the DC input to the drive.

361

Pulse In Ref Reference of the pulse input (Z channel of encoder - can be used while A & B

channels are encoder inputs).

342

Scale Block 1-4 Output of scale blocks, parameters 354-355. 342

Torque Est Calculated percentage of rated motor torque. 342

Torque Setpt 1 Selects “Torque Stpt1” for [Torque Ref A Sel] when set, otherwise uses value selected

in [Torque Ref A Sel].

361

Loading...

Loading...