Programming and Parameters 3-57

INPUTS & OUTPUTS

Digital Inputs

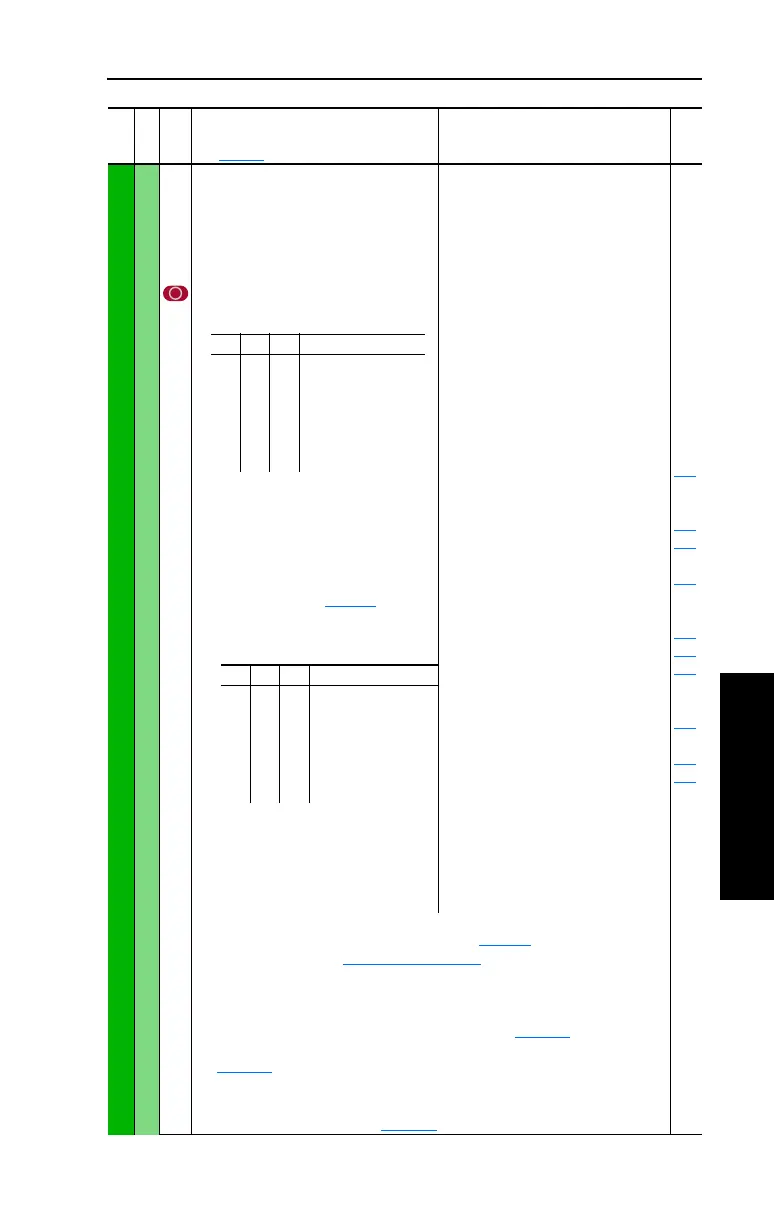

361

362

363

364

365

366

[Digital In1 Sel]

[Digital In2 Sel]

[Digital In3 Sel]

[Digital In4 Sel]

[Digital In5 Sel]

[Digital In6 Sel]

(11)

Selects the function for the digital inputs.

(1)

Speed Select Inputs.

To access Preset Speed 1, set [Speed

Ref x Sel] to “Preset Speed 1”.

Type 2 Alarms - Some digital input

programming may cause conflicts that

will result in a Type 2 alarm. Example:

[Digital In1 Sel] set to “5, Start” in 3-wire

control and [Digital In2 Sel] set to 7

“Run” in2-wire. See Table 4.C for info on

resolving this type of conflict.

(2)

Vector Control Option Only.

(4)

When [Digital Inx Sel] is set to option 2

“Clear Faults” the Stop button cannot be

used to clear a fault condition.

(5)

Typical 3-Wire Inputs - Only 3-wire

functions are allowed. Including 2-wire

selections will cause a type 2 alarm.

Default:

Default:

Default:

Default:

Default:

Default:

Options:

4

5

18

15

16

17

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15-17

18

19

20

21

22

23

24

25

26

27

28

29

30

31-33

34

35

36

37

38

“Stop – CF”

“Start”

“Auto/ Manual”

“Speed Sel 1”

“Speed Sel 2”

“Speed Sel 3”

“Not Used”

“Enable”

(8,10)

“Clear Faults”(CF)

(4)

“Aux Fault”

“Stop – CF”

(10)

“Start”

(5, 9)

“Fwd/ Reverse”

(5)

“Run”

(6, 10)

“Run Forward”

(6)

“Run Reverse”

(6)

“Jog”

(5)

“Jog1”

(2)

“Jog Forward”

(6)

“Jog Reverse”

(6)

“Stop Mode B”

“Bus Reg Md B”

“Speed Sel 1-3”

(1)

“Auto/ Manual”

(7)

“Local”

“Acc2 & Dec2”

“Accel 2”

“Decel 2”

“MOP Inc”

(14)

“MOP Dec”

(14)

“Excl Link”

(14)

“PI Enable”

“PI Hold”

“PI Reset”

“Pwr Loss Lvl”

“Precharge En”

(14)

“Spd/Trq Sel1-3”

(2,3)

“Jog 2”

(2)

“PI Invert”

(12)

“Torque Setpt 1”

(12,14)

“Micro Pos”

(12, 13, 14)

“Fast Stop”

(12, 14)

100

156

162

096

141

143

195

194

380

124

(6)

Typical 2-Wire Inputs - Requires that only 2-wire functions are chosen. Including

3-wire selections will cause a type 2 alarm. See Table 4.C for conflicts.

(7)

Auto/Manual - Refer to Figure 1.10 on page 1-22 for details.

(8)

Opening an “Enable” input will cause the motor to coast-to-stop, ignoring any

programmed Stop modes.

(9)

“Dig In ConflictB” alarm will occur if a “Start” input is programmed without a “Stop” input.

(10)

Refer to the Sleep-Wake Mode Attention statement on page 3-36.

(11)

A dedicated hardware enable input is available via a jumper selection. Refer to

page 1-19

for further information.

(12)

Vector firmware 3.001 and later.

(13)

Only available when “Torque Proving” function is selected.

(14)

Refer to Option Definitions on page 3-56.

File

Group

No.

Parameter Name & Description

See page 3-2 for symbol descriptions

Values

Related

321Auto Reference Source

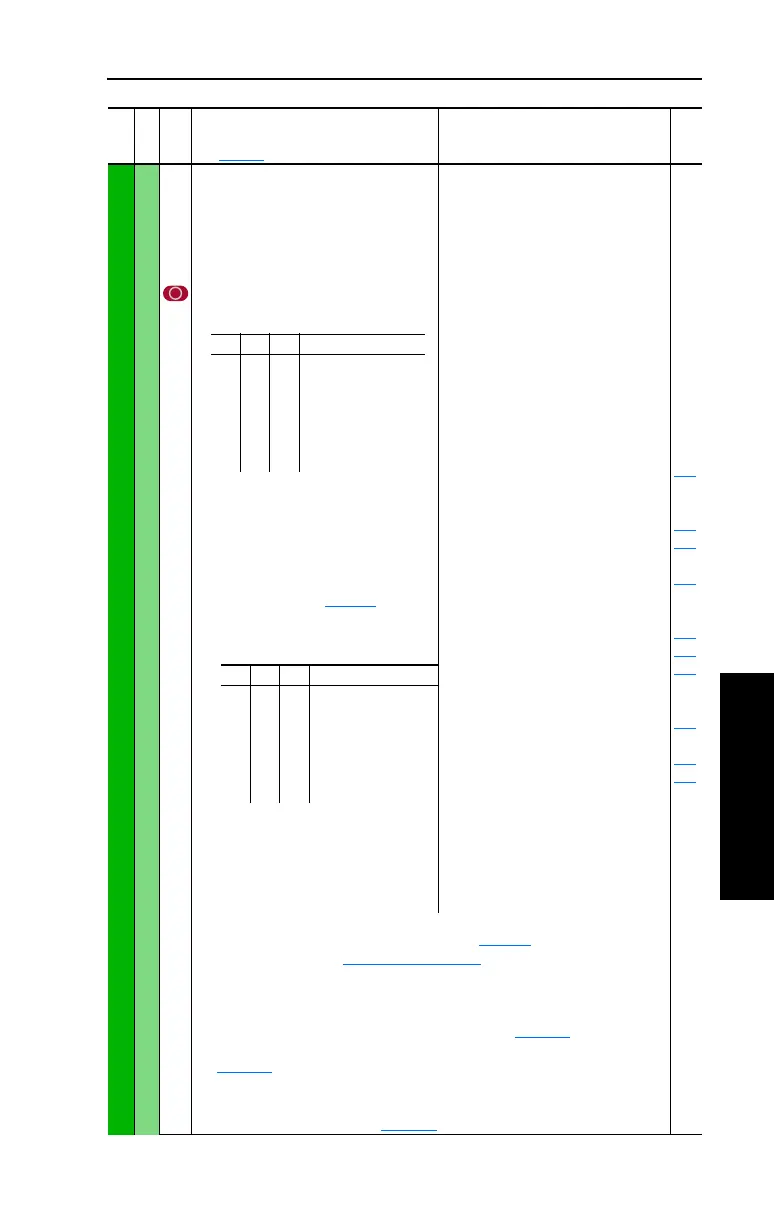

0

0

0

0

1

1

1

1

0

0

1

1

0

0

1

1

0

1

0

1

0

1

0

1

Reference A

Reference B

Preset Speed 2

Preset Speed 3

Preset Speed 4

Preset Speed 5

Preset Speed 6

Preset Speed 7

3

3 2 1 Spd/Trq Mode

0

0

0

0

1

1

1

1

0

0

1

1

0

0

1

1

0

1

0

1

0

1

0

1

Zero Torque

Spd Reg

Torque Reg

Min Spd/Trq

Max Spd/Trq

Sum Spd/Trq

Absolute

Zero Trq

Loading...

Loading...