Programming and Parameters 3-27

SPEED COMMAND

Process PI

Important: Parameters in the Process PI Group are used to enable and tune the

PI Loop. In order to allow the PI Loop to control drive operation, program the

following:

Standard Control Option – Parameter 080 [Speed Mode] must be set to 2

“Process PI” and parameter 125, bit 0 must be set to “1, Enabled.”.

Vector Control Option – Only requires setting parameter 125, bit 0 to “1, Enabled.”

124 [PI Configuration]

Sets configuration of the PI regulator.

124

thru

138

125 [PI Control]

Controls the PI regulator.

080

126 [PI Reference Sel]

Selects the source of the PI reference.

(1)

Vector firmware 3.001 and later.

Default:

Options:

0

0

1

2

3-6

7

8

9

10

11-17

18-22

23-24

25

26

27

28

“PI Setpoint”

“PI Setpoint”

“Analog In 1”

“Analog In 2”

“Reserved”

“Pulse In”

“Encoder”

“MOP Level”

“Master Ref”

“Preset Spd1-7”

“DPI Port 1-5”

“Reserved”

“Scale Block 1”

(1)

“Scale Block 2”

(1)

“Scale Block 3”

(1)

“Scale Block 4”

(1)

024

124

thru

138

127 [PI Setpoint]

Provides an internal fixed value for

process setpoint when [PI Reference Sel]

is set to “PI Setpoint.”

Default:

Min/Max:

Units:

50.00%

–/+100.00% of Maximum

Process Value

0.01%

124

thru

138

File

Group

No.

Parameter Name & Description

See page 3-2 for symbol descriptions

Values

Related

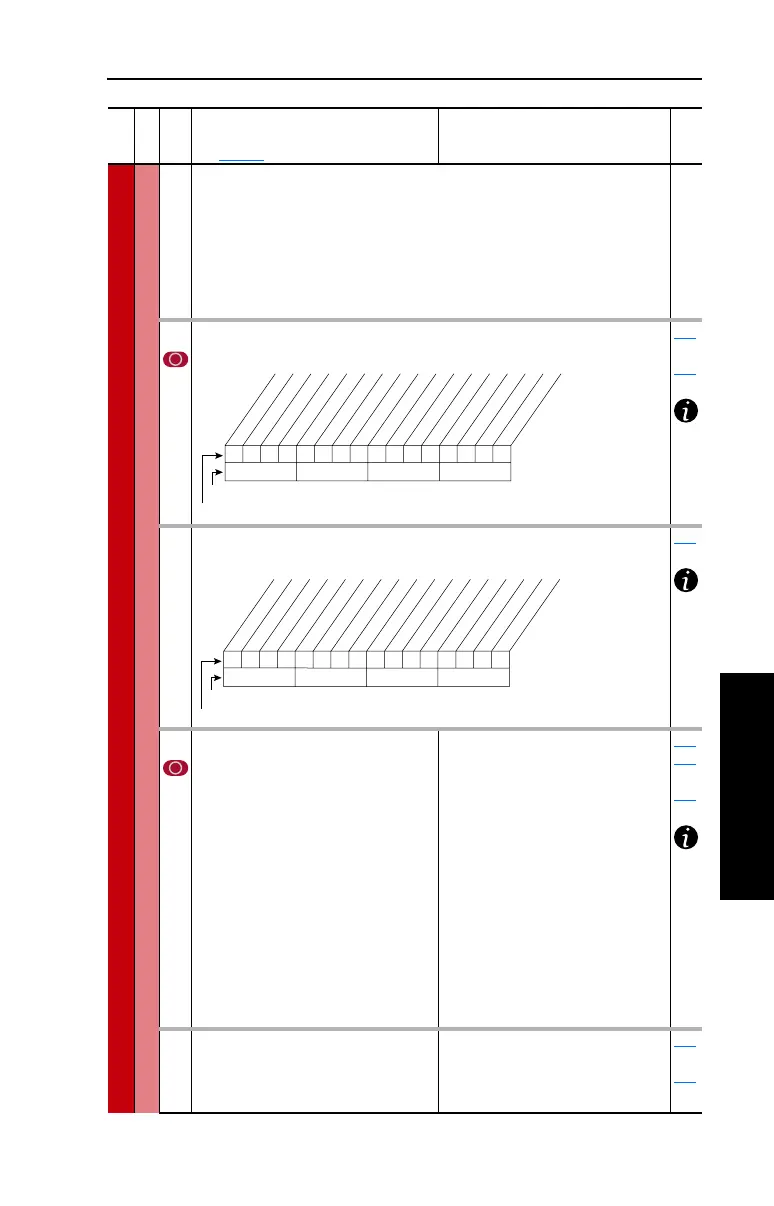

0000000000xxxxxx

10 01234567891112131415

1 =Enabled

0 =Disabled

x =Reserved

Bit # * Vector Control Option Only

** Vector firmware 3.001 & later

Factory Default Bit Values

Excl Mode

Invert Error

Preload Mode

Ramp Ref

Zero Clamp

Feedbak Sqrt

Stop Mode

Anti-Wind Up

Torque Trim *

% of Ref **

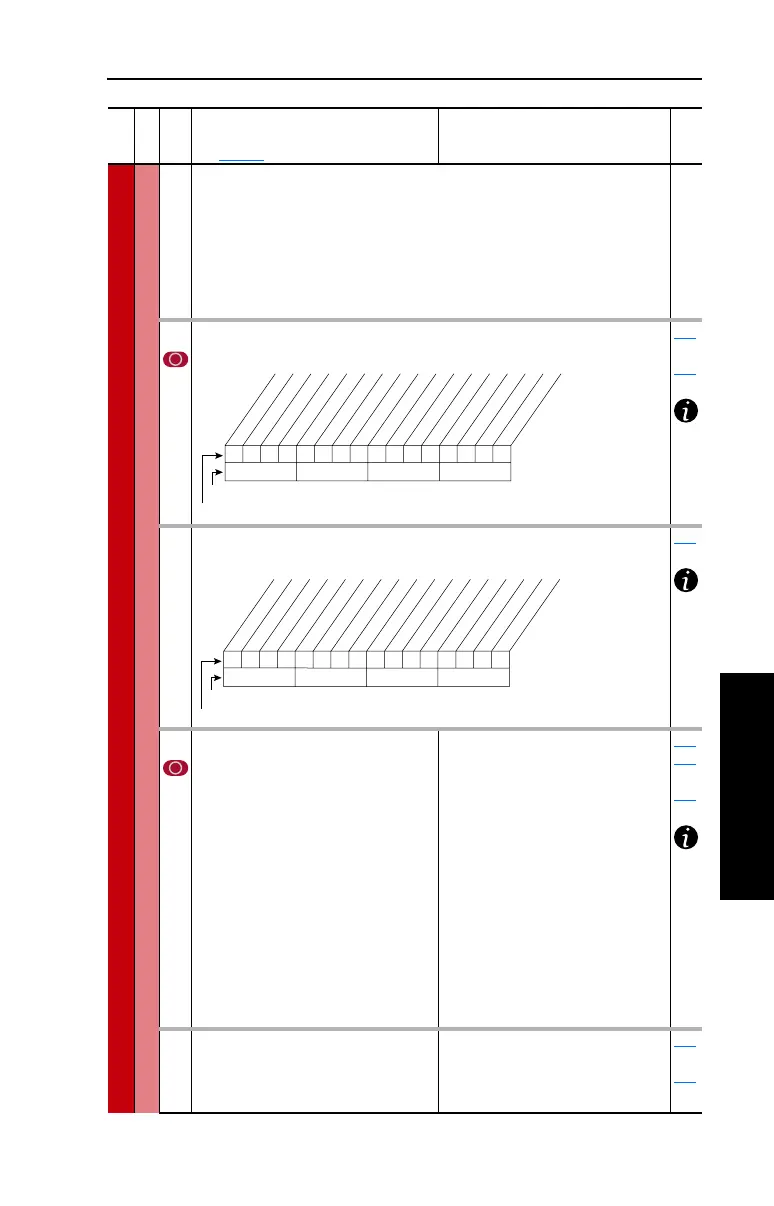

00x 0xxxxxxxxxxxx

10 01234567891112131415

1 =Enabled

0 =Disabled

x =Reserved

Bit #

Factory Default Bit Values

PI Enable

PI Hold

PI Reset

Loading...

Loading...