Application Notes C-5

Installation/Wiring

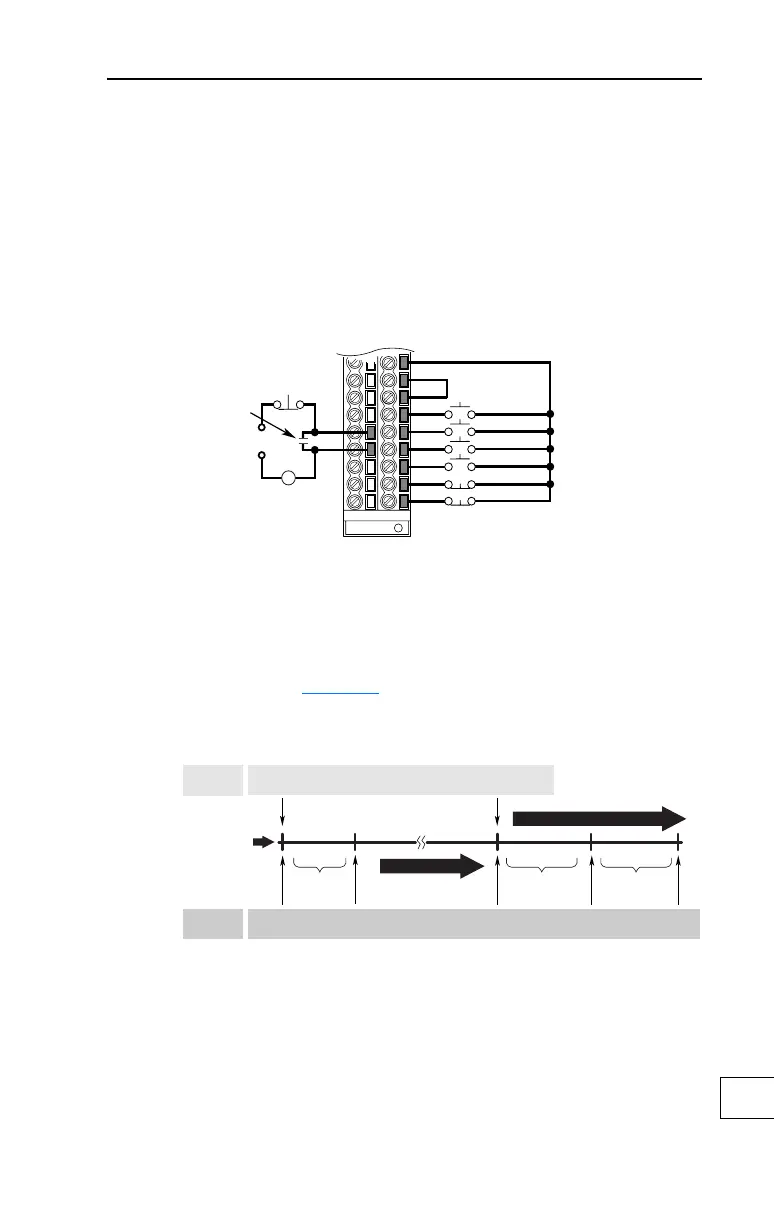

When [TorqProve Cnfg] is set to “Enable,” the Digital Out 1 relay is

used to control the external brake contactor. The normally open (N.O.)

contact, when closed, is intended to energize the contactor. This provides

the mechanical brake with voltage, causing the brake to release. Any

interruption of power to the contactor will set the mechanical brake.

Programming [Digital Out1 Sel], parameter 380 will be ignored when

[TorqProve Cnfg] is set to “Enable.”

Figure C.2 Typical Torque Proving Configuration

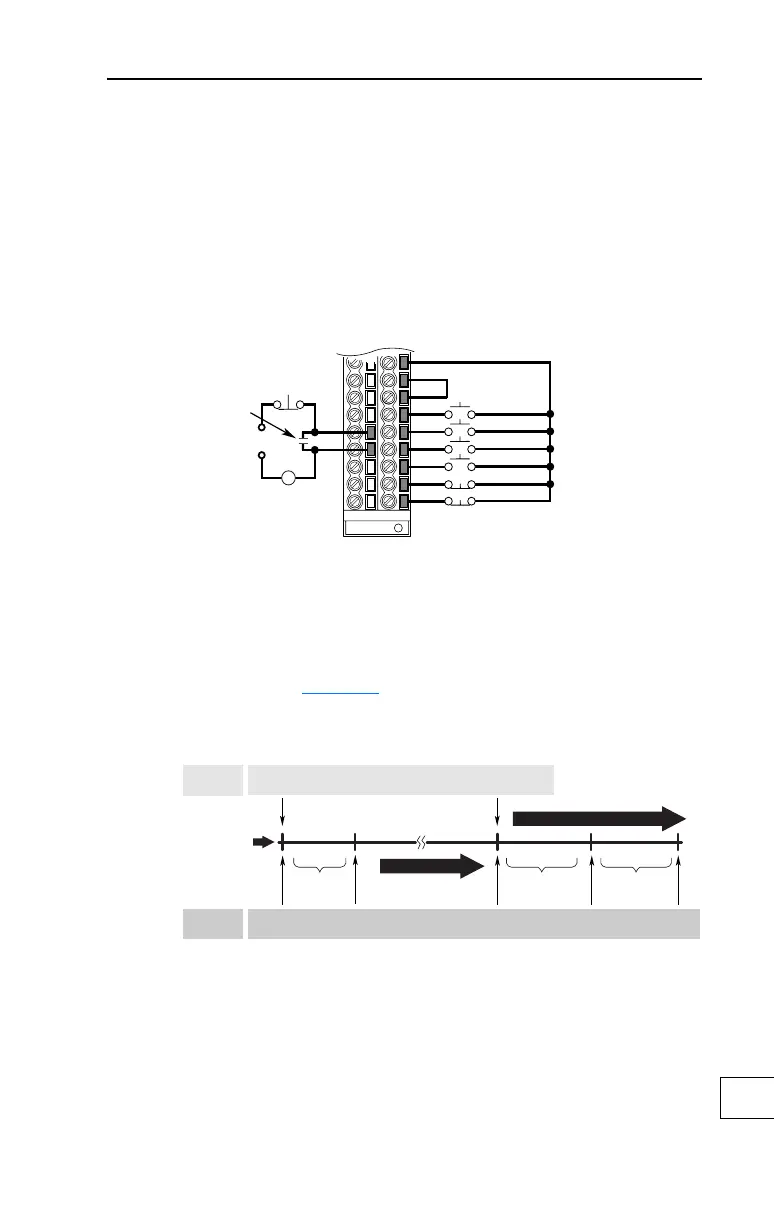

Lifting/Torque Proving Application Programming

The PowerFlex 700 lifting application is mainly influenced by

parameters 600 through 611 in the Torque Proving group of the

Application file. Figure C.3

and the paragraphs that follow describe

programming.

Figure C.3 Torque Proving Flow Diagram

24

25

26

27

28

29

30

31

32

Run Fwd

Run Rev

Clear Faults

Float/Micro

Fast Stop

Enable

12

13

115V AC

Brake

Contactor

Brake Set

Normally Open

= Brake Set

24V configuration shown,

see page 1-21 for other examples

.

Torque

Prove Initiated

Brake

Released

Float

Initiated

Brake

Set

Brake

Slip Test

Run

Command

Run

Command Released

Drive Running

Run can be initiated anytime

All times between Drive Actions are programmable and can be made very small

(i.e. Brake Release Time can be 0.1 seconds)

[ZeroSpdFloatTime]

Parameter 605

[Brk Release Time]

Parameter 604

[Brk Set Time]

Parameter 607

Operator

Commands

Time

Drive

Actions

Loading...

Loading...