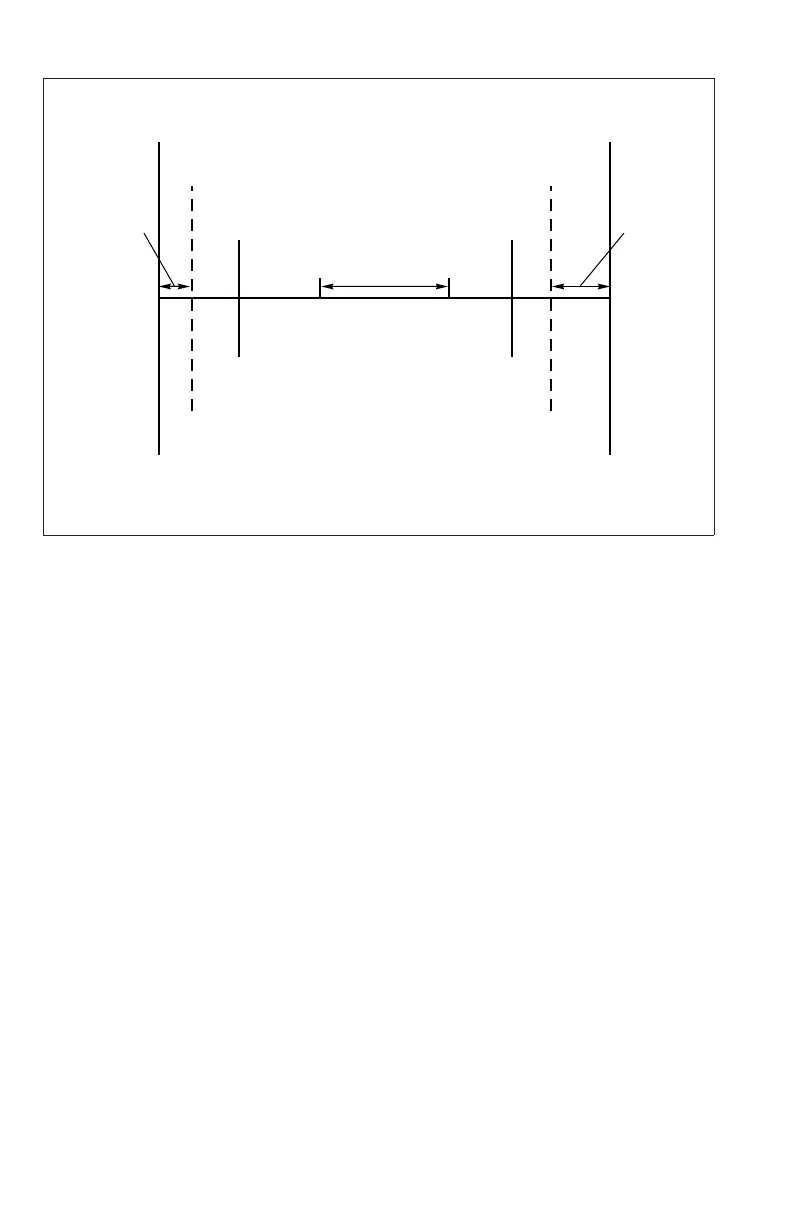

b. Throttle Position Sensor (TPS) Adjustment—Using Diagnostic Tool. When

properly installed by the equipment manufacturer, the TPS should not need

adjustment. If TPS adjustment is necessary, confirm that it has been installed to

Allison Transmission specification (refer to Figure 5–5). The TPS is

self-calibrating and therefore has no optimum closed throttle or full throttle count

value. Idle count should be 50 or higher and full throttle count 200 or lower. As

long as the counts are in the 50 and 200 count range with a difference of 85 to

130 counts between closed and full throttle the TPS is set correctly.

Error codes occur if the idle position is less than 14 counts or when the full

throttle position is more than 233 counts.

The Allison DOC™ For PC–Service Tool can read TPS counts. Watch the TPS

movements as the controls move it through a full stroke. Be sure the following

conditions DO NOT EXIST:

• Misalignment or obstruction to smooth movement through the full stroke

• Idle and full throttle positions are not within an error zone (refer to

Figure 5–5)

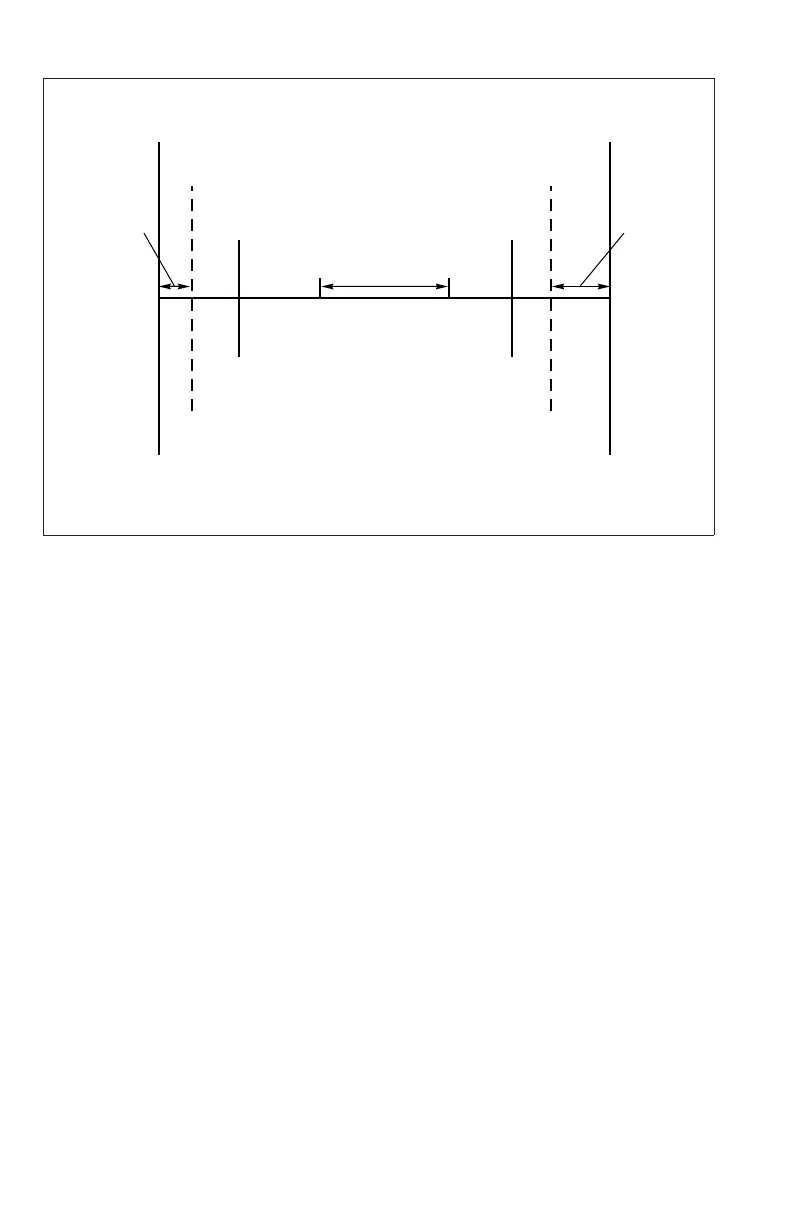

c. Hitch-Pin Throttle Position Sensor Installation.

• Install the throttle sensor body as follows:

1. Clamp cable end using clamp and shims (refer to Figure 5–6).

0 COUNT

14 COUNTS

50 COUNTS

CLOSED

THROTTLE

WIDE OPEN

THROTTLE

233 COUNTS

255 COUNTS

200 COUNTS

APPROX.

19 mm (0.75 in.) STROKE

FULLY

EXTENDED

ERROR

ZONE

ERROR

ZONE

FULLY

RETRACTED

(AT REST)

Total Stroke

CT–WOT

15.2 mm–22.9 mm

(0.6 in.–0.9 in.)

85–130 Counts

Adjust so total stroke is within

50–200 count band

0 mm

2.5 mm

(0.1 in.)

40.6 mm

(1.6 in.)

45.7 mm

(1.8 in.)

V00429.05

Figure 5–5. Throttle Position Determination Diagram

66

Loading...

Loading...