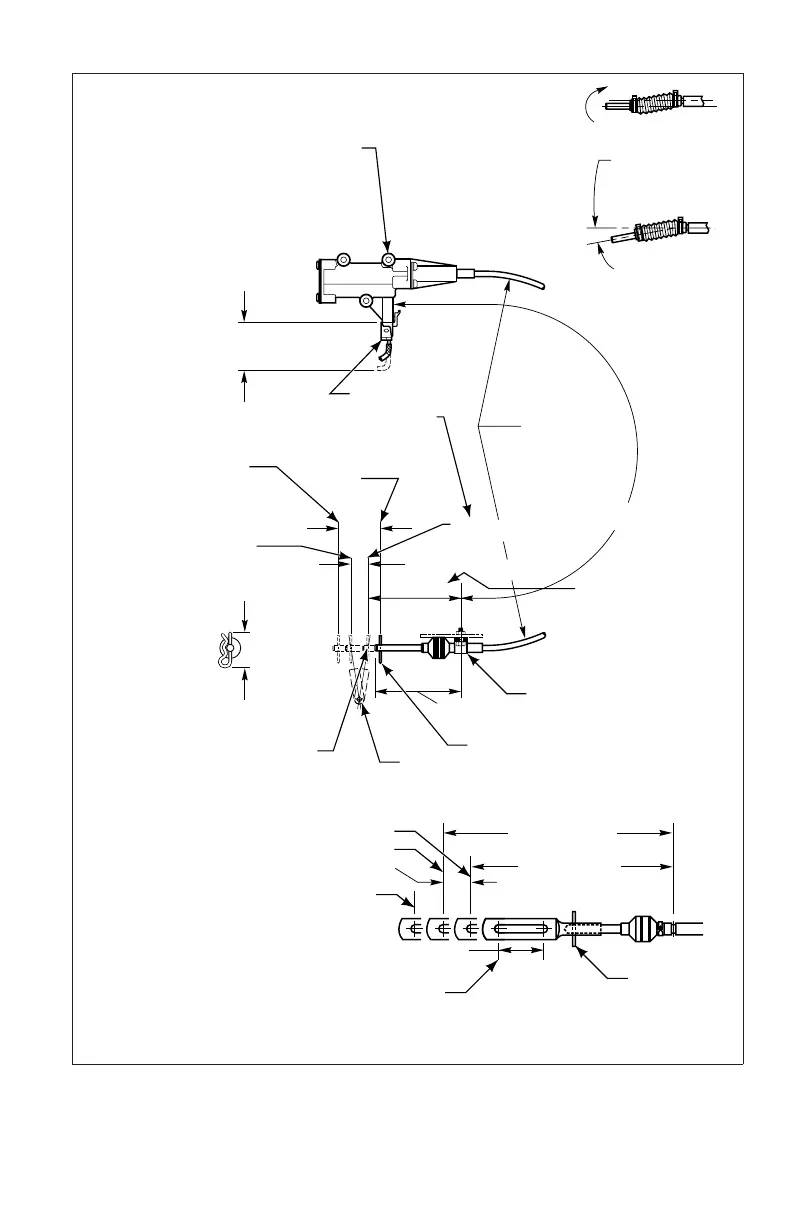

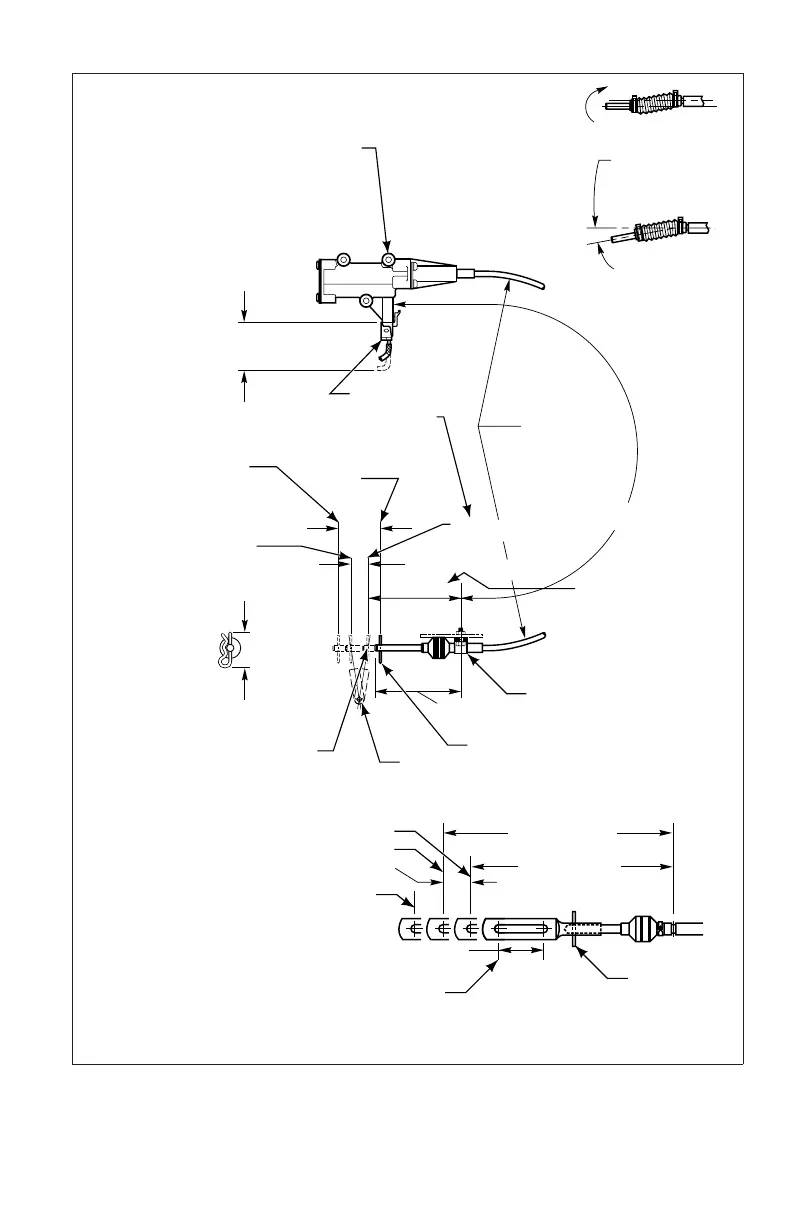

Fuel lever attachment linkage or bracket must

allow fuel lever to return to closed throttle position

when sensor rod is maintained at full throttle position.

Attach the throttle sensor directly to the engine fuel

lever with no breakover or yield linkages between the

engine fuel lever shaft and the attachment point of the

throttle sensor.

MOUNTING PROVISION:

Use M6 x 1.00 or

1

⁄4-20 in. series bolts 3 places

Torque M6 x 1.00 bolt to 10–13 N•m (84–120 lb in.)

Torque

1

⁄4-20 in. series bolts to 13–14 N•m (108–132 lb in.)

Mount to a solid frame member. Flatness of

chassis mounting surface must not exceed

0.8 mm (0.03 in.).

R 152.0 mm (6.00 in.) MIN

ALLOWANCE RADIUS

FULLY

RETRACTED

FULL THROTTLE

118.1 mm (4.65 in.)

30.2 mm (1.19 in.)

55.0 mm (2.17 in.)

MIN REQUIRED

FOR CONNECTION

REMOVAL

WIRING HARNESS

OPERATING BAND 15.2 – 22.9 mm

(0.6 – 0.9 in.)

47.5 mm (1.87 in.)

118.1 mm

(4.65 in.)

95.2 mm

(3.75 in.)

93.45 mm (3.679 in.)

87.15 mm (3.431 in.)

HITCH PIN CLIP

ENGINE FUEL LEVER

Attach to engine or governor

housing using clamp and shims as

required. Clamp must positively

lock in cable groove.

FULLY EXTENDED

FORCE REQUIRED

26.7 N (6.0 LB) MAX

Fuel control must not move

the throttle sensor beyond

the closed throttle position

at any time.

The location of the

clamping bracket relative

to the fuel lever at closed

throttle must be maintained

within this range.

(NOTE: Mounting length

+ 50.8 mm (2 inches) equals

cable length)

CLOSED THROTTLE

95.2 mm (3.75 in.)

MOUNTING

LENGTH

BENDING LOAD

APPLIED

UNACCEPTABLE INSTALLATION

Attachment must provide freedom

of motion to allow cable loading in

tension only (no bending loads).

ACCEPTABLE INSTALLATION

10.0

°

MAX INSTALLED

OPERATING ANGLE

IN ALL DIRECTIONS

LOADING IN

TENSION ONLY

V00430.06

HITCH PIN CLIP

38.1 mm (1.50 in.)

FULLY RETRACTED

FULLY EXTENDED

CLOSED THROTTLE

183.1 mm (7.21 in.) MAX

FULL THROTTLE

SAME AS WITHOUT

SLIP LINK

OPTIONAL THROTTLE SENSOR ASSEMBLY WITH SLIP LINK

160.2 mm (6.31 in.) MIN

Figure 5–6. Hitch-Pin Throttle Position Sensor Installation Diagram

67

Loading...

Loading...