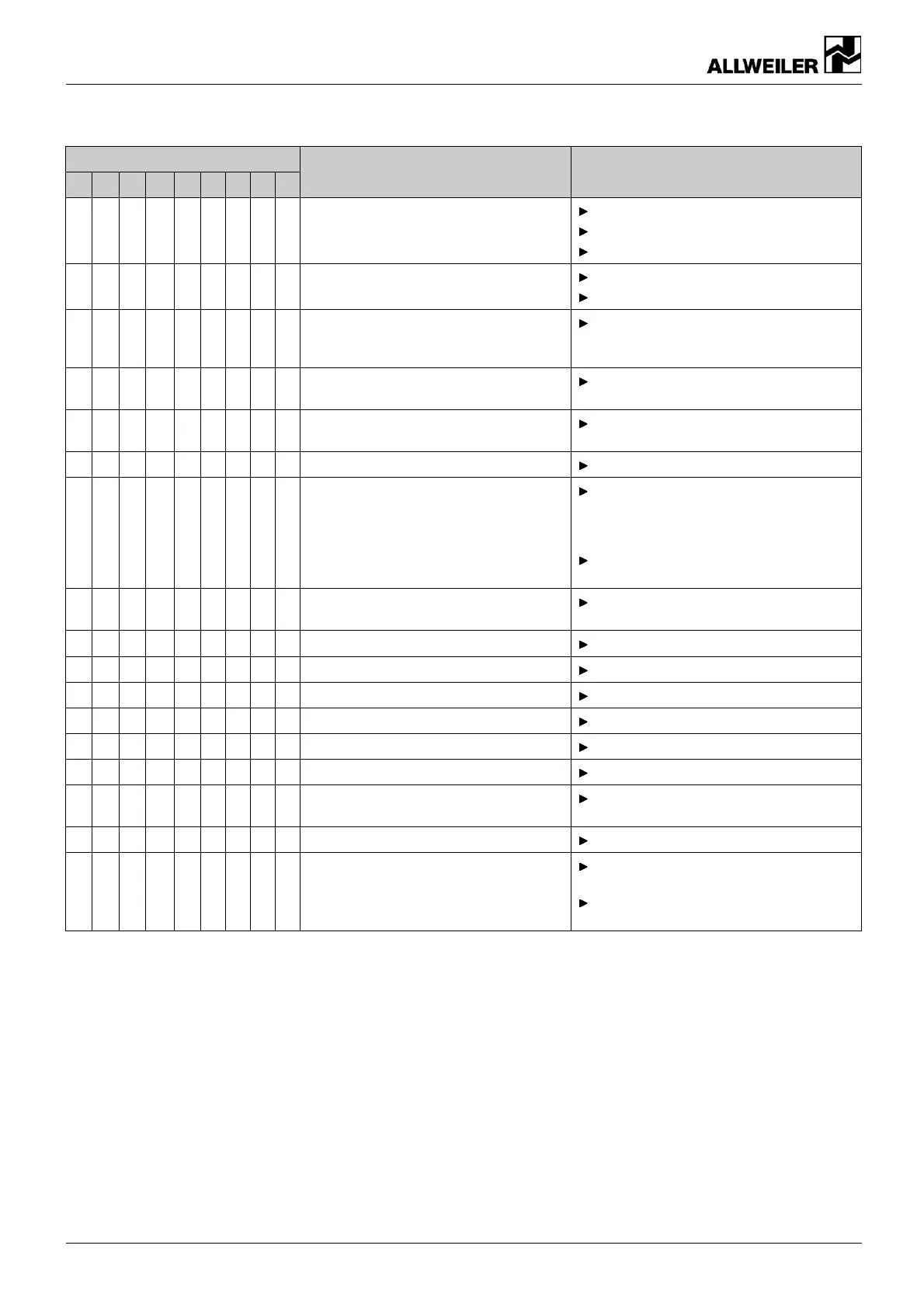

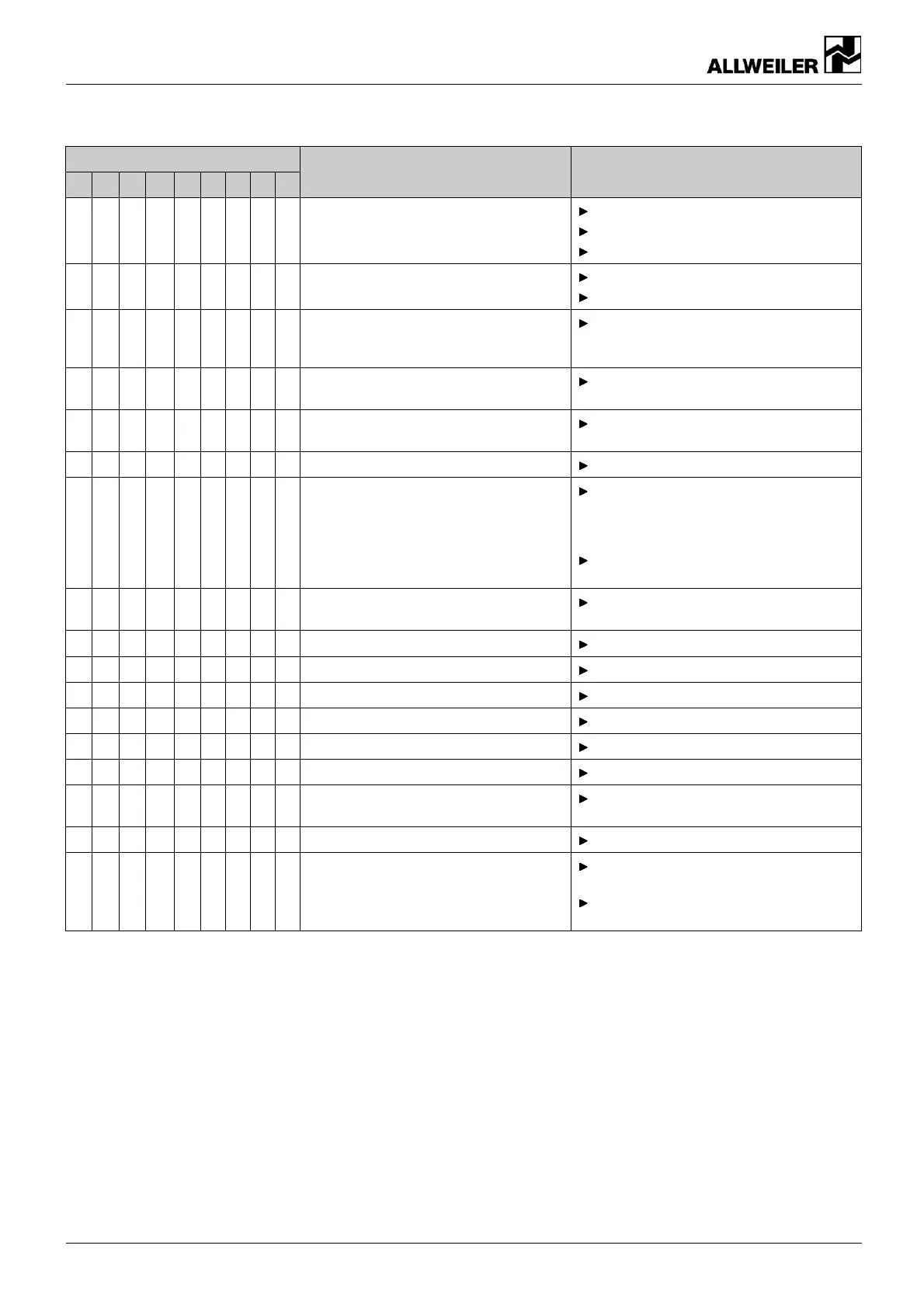

Troubleshooting

Malfunction number

12 34

5

6

7

89

Cause

Remedy

–

X

–

XX

–––

Pumped liquid temperature too hig h:

pump is cavitating

Increase the pump inlet pressure.

Lower the temperature.

Consult the manufacturer.

–

X

–

XX

–––

Hydraulic parts of the pump dirty, clo tte d

or encrusted

Dismount the pump.

Clean the parts.

–

X

–

X

–––

X

Viscosity or specific gravity of the pumped

liquid outside the range spec ified for the

pump

Consult the manufacturer.

–

X

–

X

–

X

––

X

Suction pipe completely or partially

blocked.

Clean suction pipe and any strainers

and filters.

–– ––

X

–––

Pressure-side fitting not opened wi d e

enough

Open the pressure-side fitting.

–

X

–

XXX

––

Pump parts worn

Replace the worn pump parts.

––

X

–

X

––

X Motor speed too high

Compare the required motor speed

with the specifications on the pump

nameplate. Replace the motor if

necessary.

Reduce the motor speed if speed control

is available.

–– –

XX

––––

Speed too high with viscous liquid: pump

is cavitating

Reduce the motor speed if speed control

is available.

–– ––

X

––

X

–

Coupling o r p ulley not correctly aligned.

Align coupling or pulley exactly again.

–– ––

XX

–

X

Antifriction bearing defective

Replace the antifriction bearing.

–– –– –

X

–

X

Defectiveantifrictionbearinginmotor

Replace the antifriction bearing.

–––– ––

X

–

Tie bolts not tightened prop erly

Tigh ten the tie bolts.

–––– ––

X

–

Mechanical seal worn

Replace the mechanical seal.

–––– ––

X

–

Housing seal d efective

Replace the housing s eal.

–– ––

X X X X Pump distorted

Check the pipe connections and pump

attachment.

–– ––

X

–––

Coupling elements worn

Replace the coupling elements.

–

X

–

XX

––

X Motor runn ing on 2 phases

Check the fuse and replace it if

necessary.

Check the cable conne ctions and

insulation.

Tab. 10 Pump troubleshooting list

32 AE BA-2020.05 en-US 260371 – 176-982/0

Loading...

Loading...