Appendix

9.2 Technical specifications

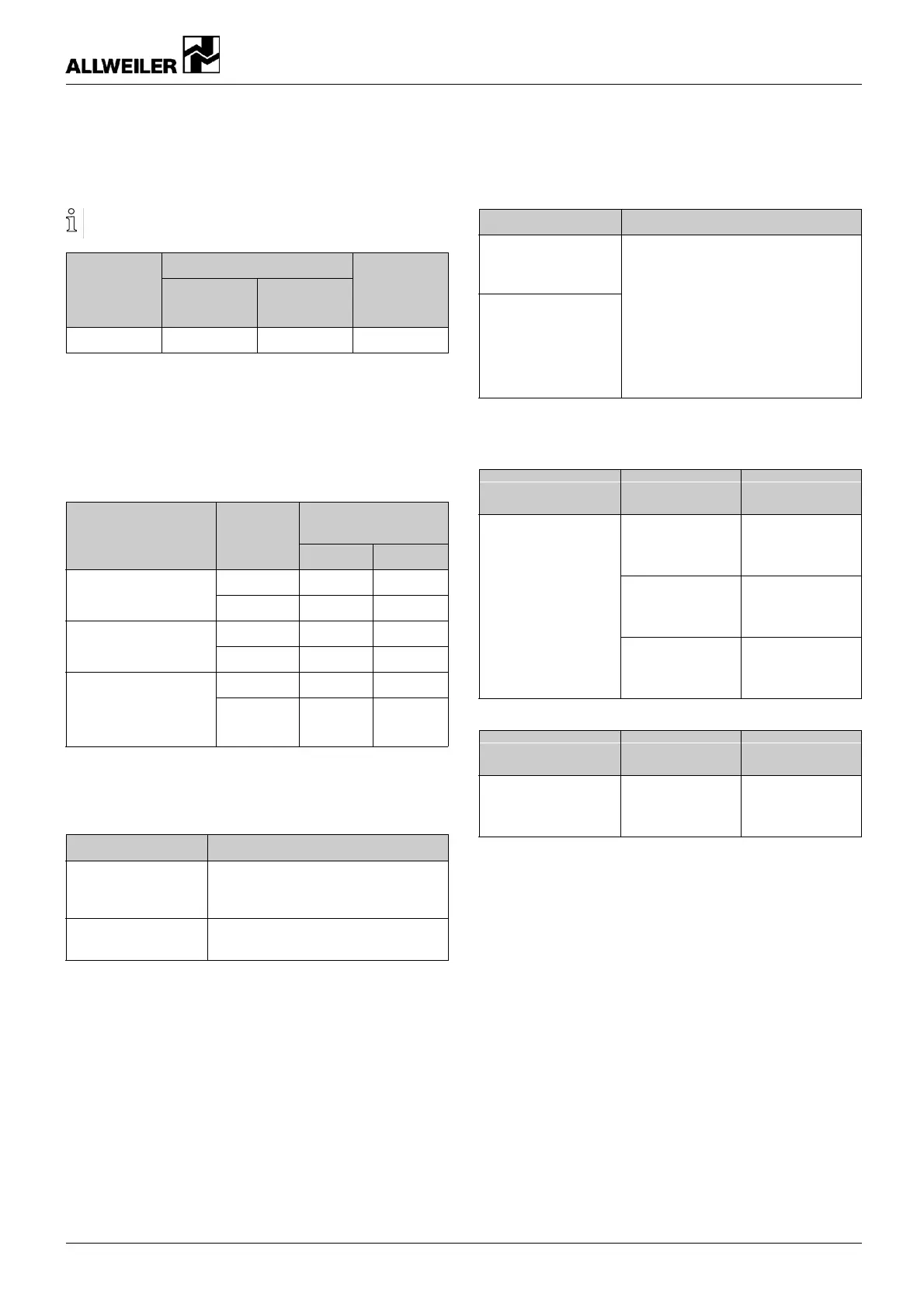

9.2.1 Ambient conditions

Operation under any other ambient conditions should be

agreed with the m anufacturer.

Relative humidity [%]

Tempera-

ture [°C]

Long-term

Short-term

Setup

height

above sea

level [m]

–20 to +40 ≤ 85 ≤ 100 ≤ 1000

Tab. 13 Ambient conditi ons

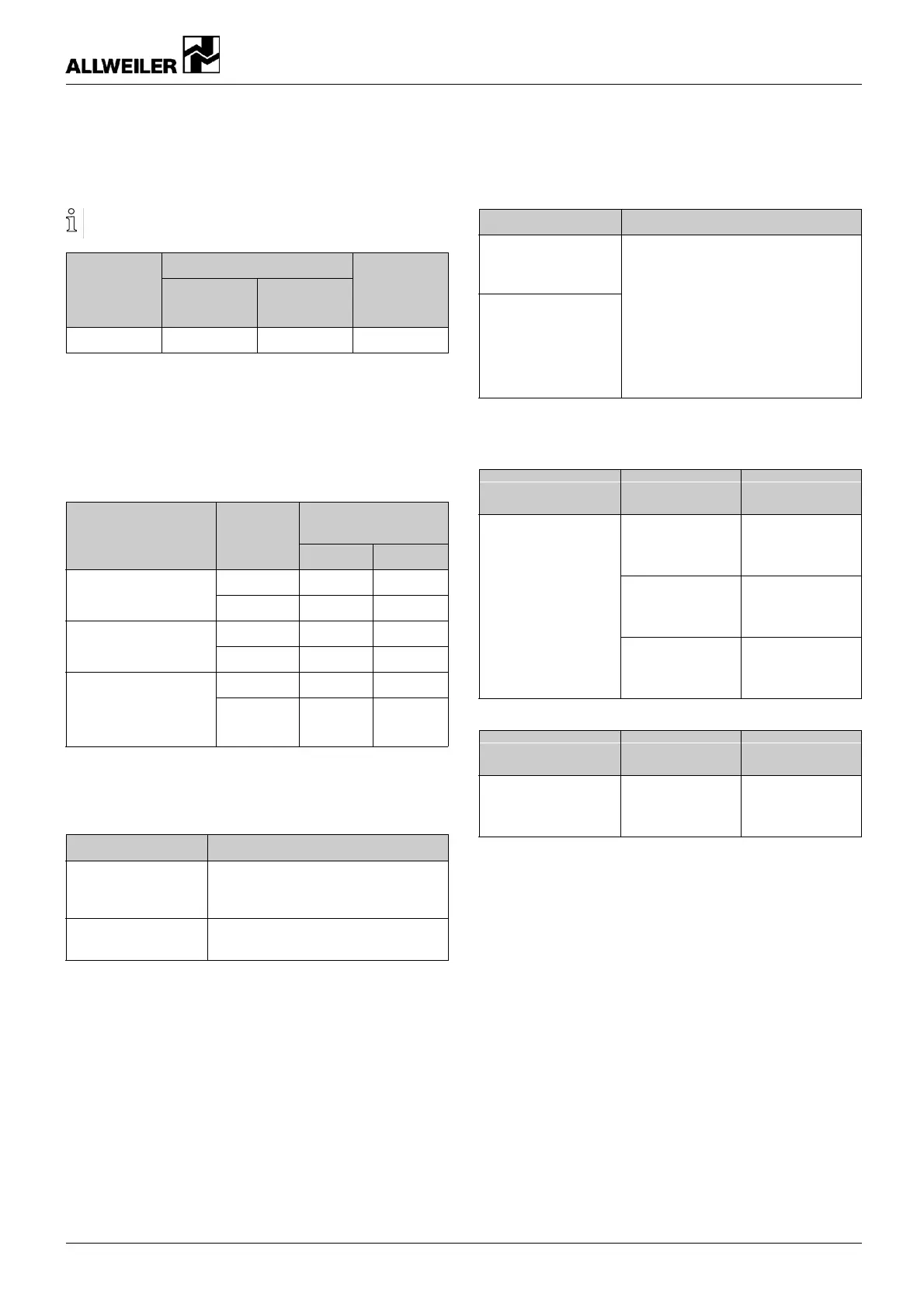

9.2.2 P reservatives

Use Valvoline preservatives or similar (recommended ),

depending on pump area

• Inside: Tectyl 502-C-EH

• Outside: Tectyl 846-K-19

Renew preservation

[months]

Type of storage Storage

duration

[months]

Interior Exterior

6–12

––

Closed,dry,dust-free

room

>12 24 36

6–12 3

–

In open air, central

European climate

>12 3 12

6–12 3

–

Outdoors, tropical

climate, aggressive

industrial atmosphere

orclosetosea

>12 3 12

Tab. 14 Type , durati on and deadlines for preservation

when storing the pump

9.2.3 Cleaning agents

Application area

Storage duration [months]

Foodstuffs and

drinking water sector

For example, spirit, Ritzol 15 5,

strong alkaline soapy solution,

steam jet (for single parts only)

Miscellaneous Benzine, wax solvents, diesel,

paraffin, alkaline cleaners

Tab. 15 Clea ning agents

9.2.4 Parameters for auxiliary systems

Sealing medium requirements:

Medium Requirements

Clean water with

low hardness

(recommended)

Other media

that meet the

requirements

• Compatible with the liquid and

all p arts touched

•Freeofsolids

• High thermal conductivity

• High boiling point

• Low viscosity

• Must not form de posi ts

Tab. 16 Seal ing medium r equirements:

Operating parameters of the shaft seals

Parameter

Shaft seal

version

Value [bar]

P02/P12

0.1–0.5 above

suction casing

pressure

P03/P13

0.5 abo ve

suction casing

pressure

Flushing and

buffering medium

pressure

P04/P14

0–0.5 above

suction casing

pressure

Tab. 17 Operating pa rameters for packing gland

Parameter

Shaft seal

version

Value [bar]

Flushing and

buffering medium

pressure

G0S/G1S

G0T/G1T

0.1–0.5 above

suction casing

pressure

Tab. 18 Operatin g parameters for mechanical seal,

single-actionwiththrottlering

260371 – 176-982/0 BA-2020.05 en-US AE 47

Loading...

Loading...