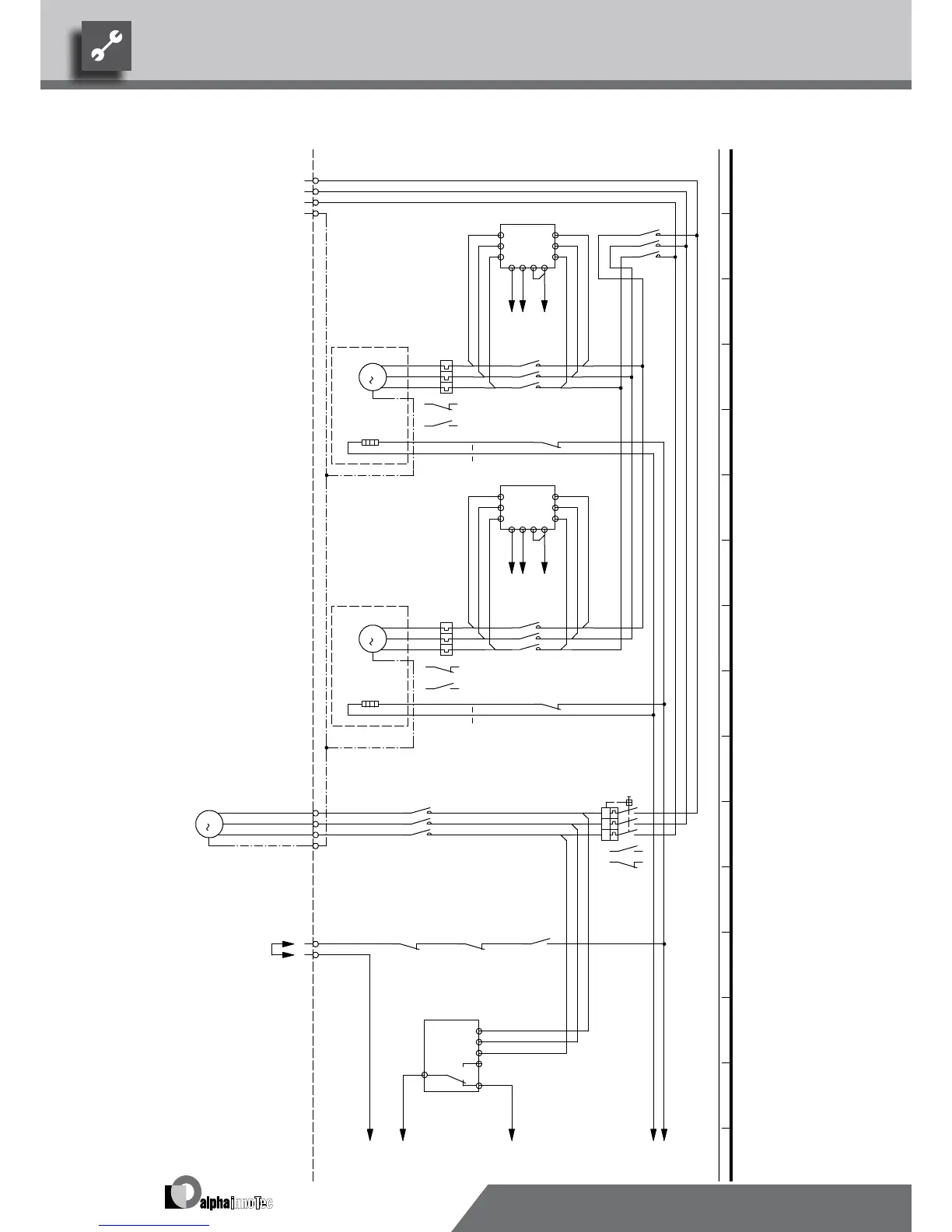

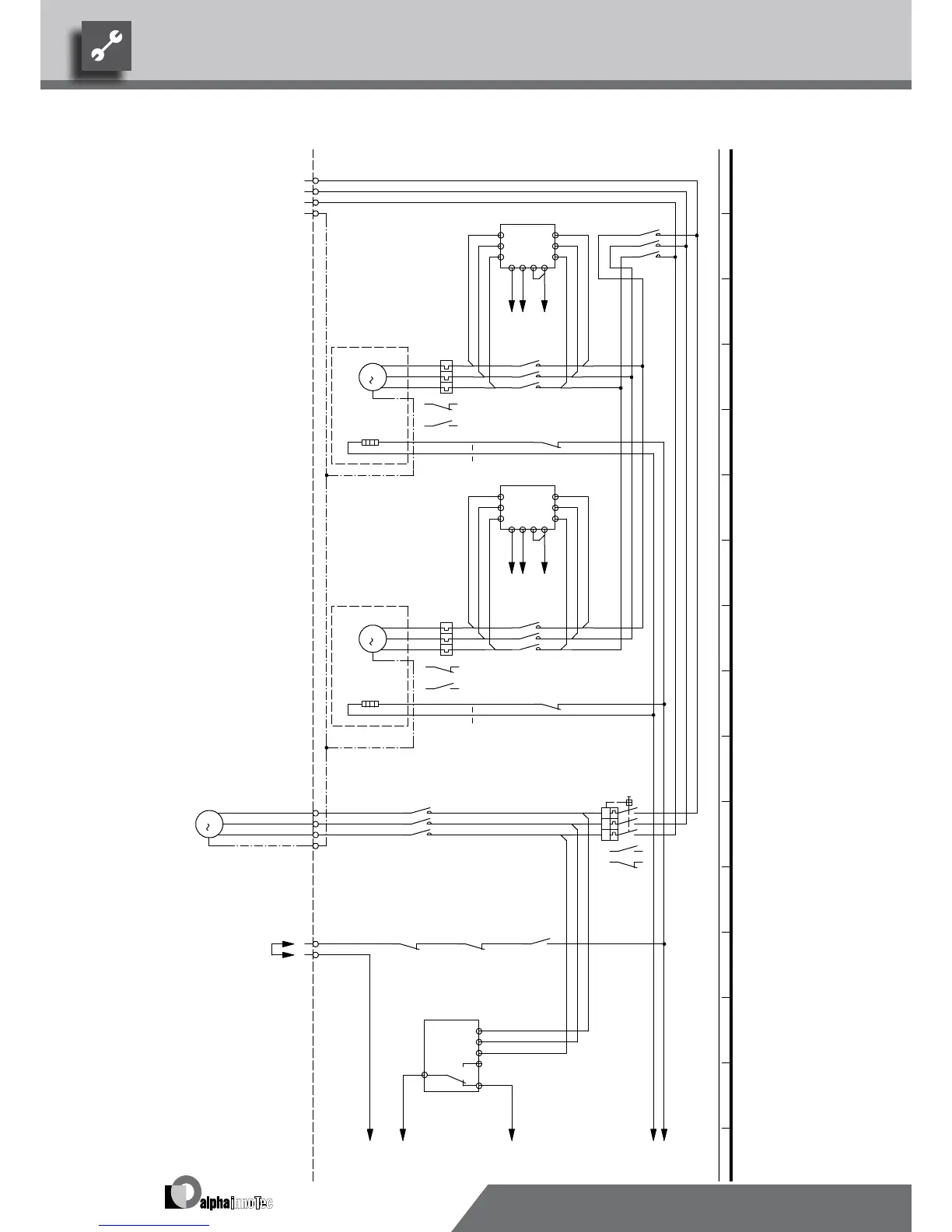

54

L1

-X7

L2 L3 PE

1

2

-K0

/2.3

3

4

A1

23

24

A2

L1 L2 L3

T1 T2 T3

-N1

5

6

VD1

/2.1

K1-A1

/2.1

A2

1

2

-K1

/2.4

3

4

1 3 5

2 4 6

-F4

M

3

T1 T2 T3 PE

-M1

VD1

5

6

9596

13

9798

21

22

-K1

/2.4

-R20

A1

23

24

A2

L1 L2 L3

T1 T2 T3

-N2

VD2

/2.1

K2-A1

/2.1

A2

/2.1

1

2

-K2

/2.5

3

4

1 3 5

2 4 6

-F5

M

3

T1 T2 T3 PE

-M2

VD2

5

6

9596

13

9798

21

22

-K2

/2.5

-R21

1

2

-K3

/2.9

4

-X7

I> I>I>

1 3 5

2 4 6

-F3

3

4

5

M

3

U1 V1 W1 PE

-M3

5

6

6 PE

1314

13

2122

13

14

-F3

11

95

96

-F4

4

95

96

-F5

8

7

-X7

8

L1 L2 L3 12 14

11

-B1

L Reg

/2.1

N Reg

/2.1

ASD

/2.1

B1-11

/2.1

MOT

/2.1

X7:7,8 Connection of external motor protection; bridge if no external motor protection can be connected.

R21

Sump heating for compressor 2

Compressor 2VD2

Motor protection switch, well / brine pump

M2

Compressor 1

Well / brine pump provided by customer

K2

Contactor, well / brine pump

VD2

Legend:

Function

F3

K1

Operating materials

K3

VD1

Mains contactor, condenserK0

VD1 Bypass contactor compressor 1

B1

X7

M3

3~PE/400V/50Hz

UK817329

3~PE/400V/50Hz

Overload relay for compressor 1

N1

F4

1

MOT

MOT

F5

N2

Starting current limit compressor 2

Starting current limit compressor 1

Bypass contactor compressor 2

BOSUP

Terminal strip in switchbox of heat pump; N/PE distribution for external 230V units

Power supply compressor; right-hand rot. field is mandatory!

1

2

Phase sequence relay; if phase sequence in the order of 11 + 14 is closed

Sump heating for compressor 1

Overload relay for compressor 2

R20

M1

2

We reserve the right to make technical changes.

UK830509/200114 © Alpha-InnoTec GmbH

SWP 540 – SWP 820 · SWP 330H – SWP 500H Circuit Diagram 1/3

Loading...

Loading...