CAUTION: Holding the nut with one hand and turning the

lever, like a regular bolt, with the other hand will not clamp the

wheel in the frame or fork securely. To securely clamp the wheel,

the full pivoting force of the quick release lever is required.

Quick release skewer mechanism set-up

The wheel hub is locked in the bicycle frame or fork by the quick

release tightening force on the one end and by the tension adjusting

nut on the other end. This force is controlled by turning the tension

adjusting nut. By turning the nut clockwise while keeping the quick

release skewer stationary, the tightening force is increased; by

turning the nut counterclockwise the tightening force is reduced.

Less than half a turn of the tension adjusting nut can reduce the

tightening force from sufficient to a hazardous level.

2. INSTALLATION AND REMOVAL OF WHEELS WITH QUICK

RELEASE SKEWERS

А. Front wheel removal

1. If your bicycle uses V-brakes, disconnect them so that the tyre

can pass between the pads (see section 5.1.C, fig. 12-15).

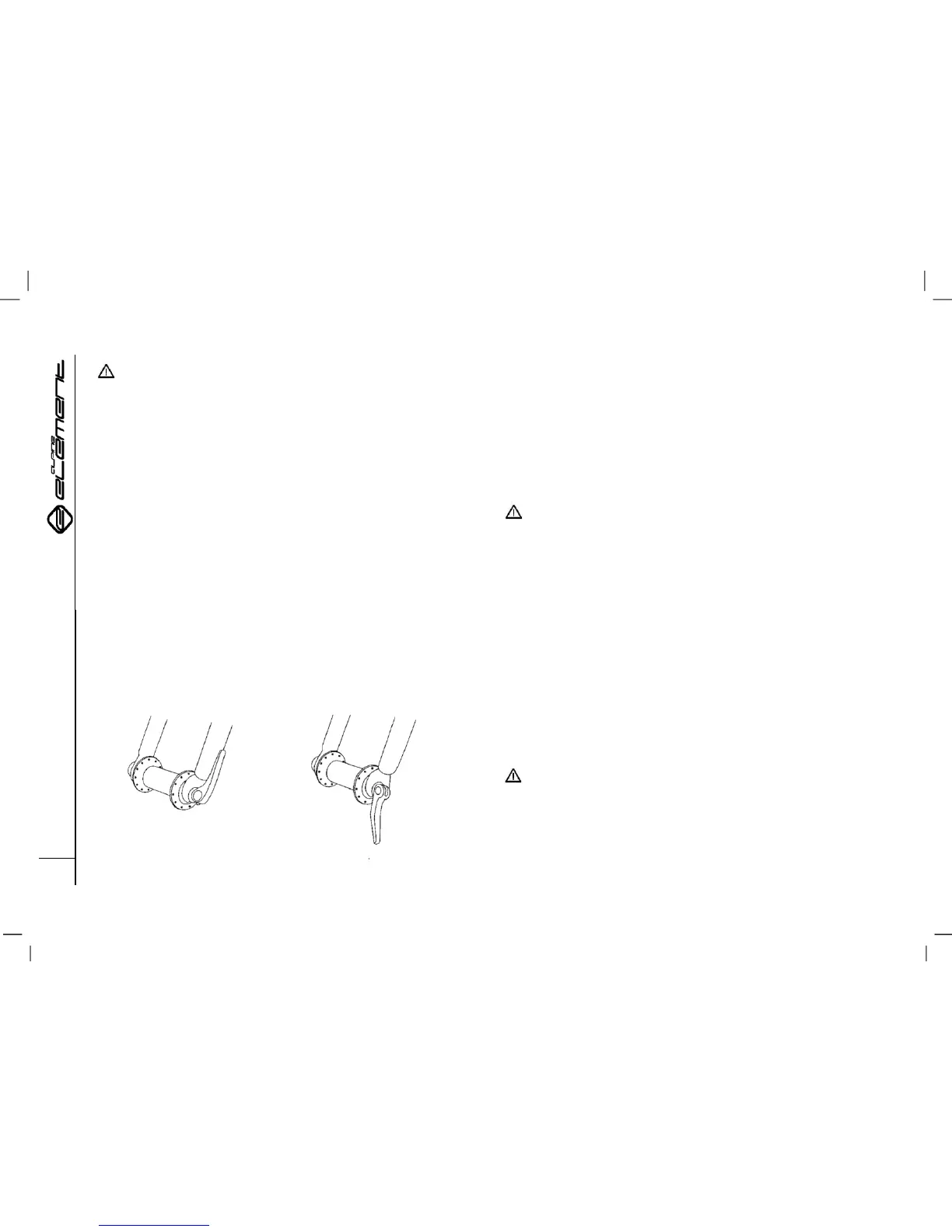

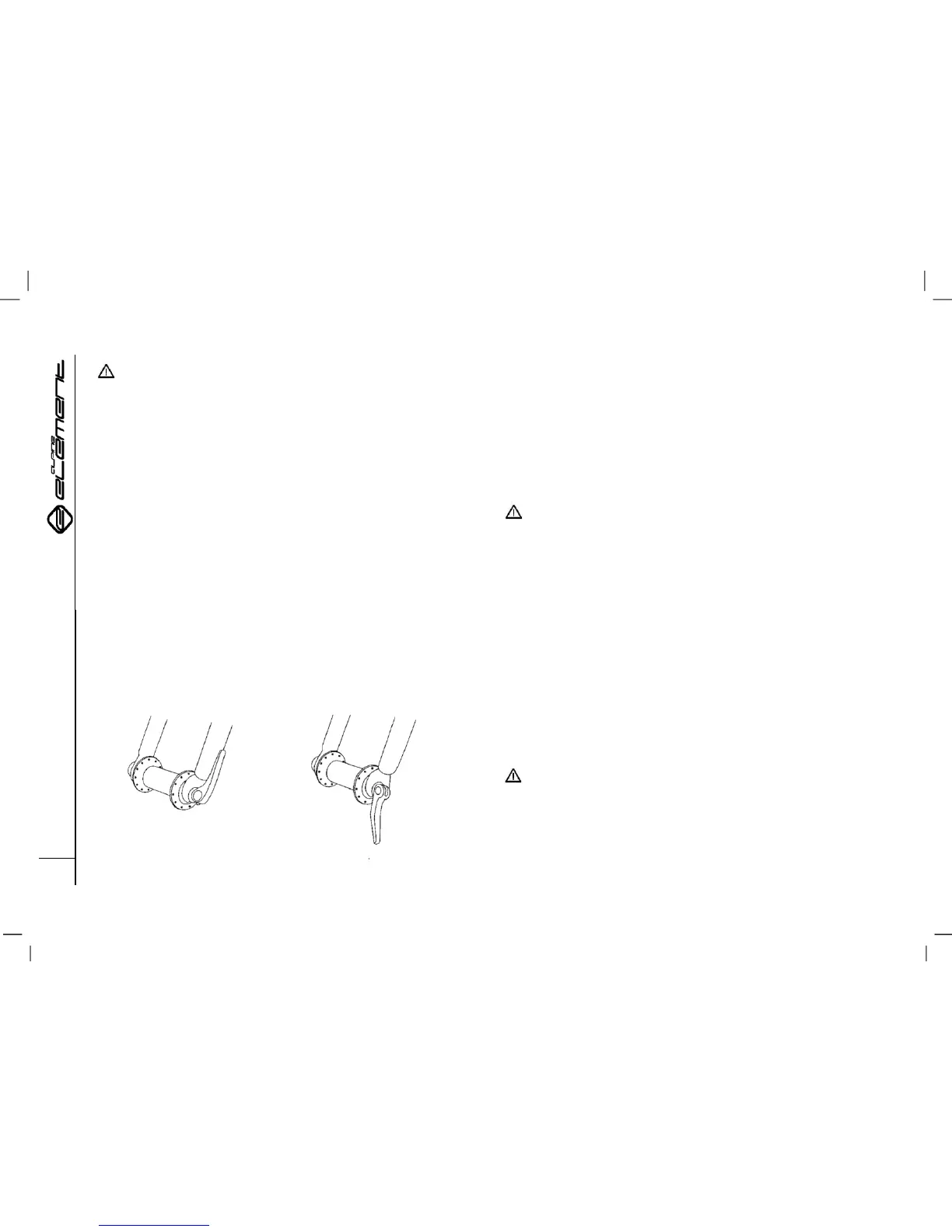

2. Turn the quick release lever from the CLOSED position to the

OPEN position (fig. 8а and 8b). 3. Loosen the tension adjusting nut

by approximately six full turns. This will prevent the quick release

skewer catching on the brake bosses, preventing the wheel from

dropping out. If there are no bosses, additional loosening of the nut

is not required.

4. Raise the front end of the bicycle 10–15 cm off the ground and

tap the wheel gently out of the fork dropouts.

B. Front wheel installation

ATTENTION: If your bicycle is equipped with disc brakes,

take care not to damage the disc, brake pads, or the calliper

when reinstalling the wheel. Never press the disc brake lever,

unless the disc is properly inserted into the calliper.

1. Put the quick release lever in the OPEN position (fig. 8b).

2. Reinstall the wheel and make sure that the hub axle is properly

seated in the fork dropouts. The quick release lever should be

located on the left side of the bicycle.

3. Holding the quick release lever in the OPEN position with your

right hand, install the tension adjusting nut with your left hand, so

that the clearance between the fork and the nut on the one end,

and the clearance between the fork and the lever on the other end

is about 1–2 mm (fig. 7).

4. Pressing down on the wheel with the fork and centring it

simultaneously, turn the quick release lever to the CLOSED

position and press it parallel to the fork “leg.”

WARNING: Apply considerable pressure to lock the

wheel securely in place. If you can fully “close” the quick

release lever without clasping your fingers around the forkleg

to increase the tightening force, and the lever does not clearly

imprint itself on your palm, the tightening force is insufficient

(fig. 8а, fig. 8b). “Open” the lever, turn the tension tightening

nut clockwise by a quarter of a turn and try again.

Loading...

Loading...