RS1300003 Rev. 0 40 December 1997

Component Testing

Component Description Test Procedures

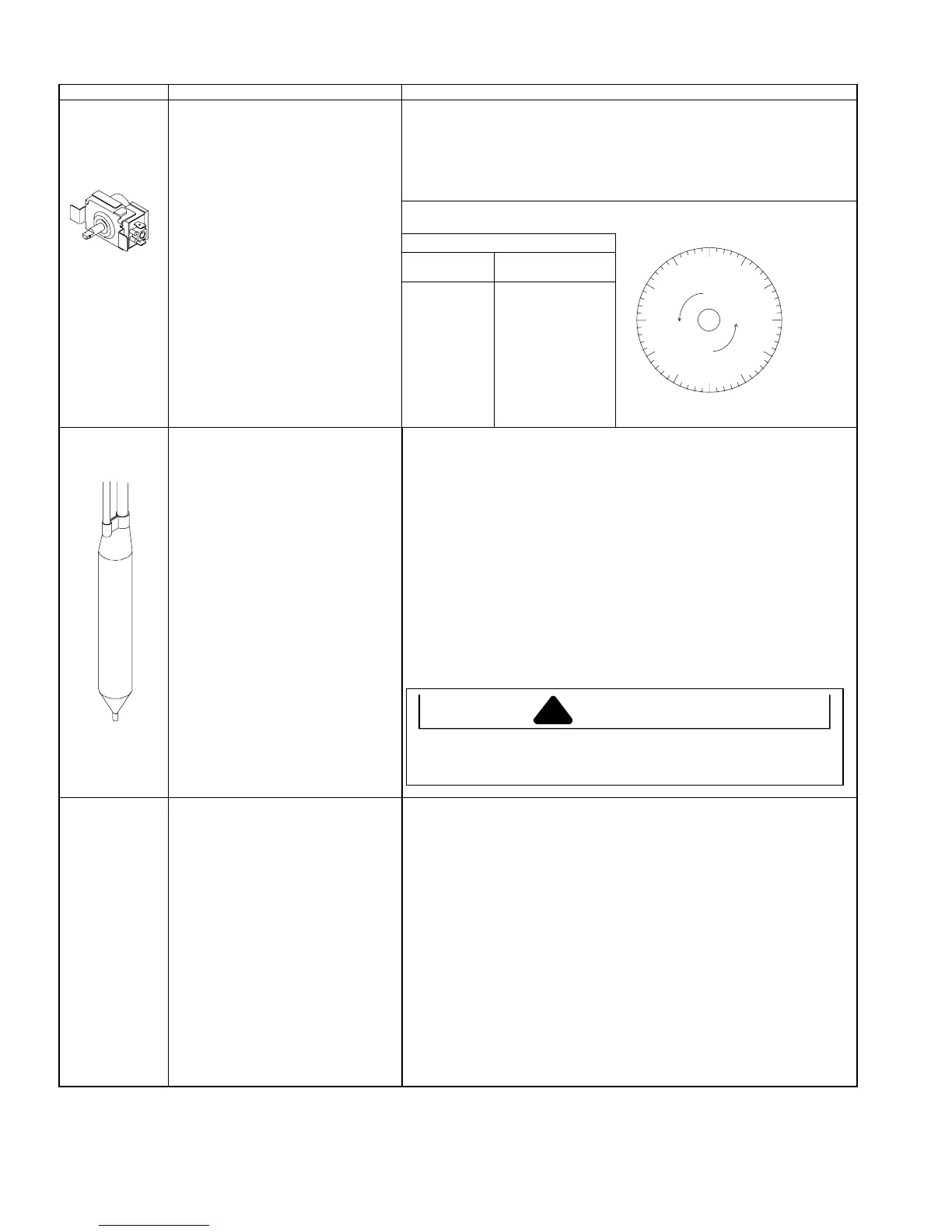

Freezer temperature control is a capillary

tube operating a single pole, single throw

switch.

Check for proper calibration with thermocouple capillary in air supply well buy

recording cut-in and cut-out temperatures in middle setting. See tech sheet for

model being serviced for expected temperatures.

Check control contacts are opening by disconnecting electrical leads to control

turning control knob to coldest setting and checking for continuity across

terminals.

Altitude correction must be done on both “cut-in” and “cut-out” screws.

Altitude Counter in Feet

Feet Clockwise Turns

Control, freezer

temperature

(Non-electronic

units)

Altitude Adjustment

When altitude adjustment is required on

a G.E. control, turn altitude adjustment

screw 1/7 turn clockwise for each 1,000

feet increase in altitude up to 10,000

feet.

In most cases the need for altitude

adjustments can be avoided by simply

turning temperature control knob to

colder setting.

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

10,000

7/60

13/60

19/60

25/60

31/60

37/60

43/60

49/60

55/60

Drier Drier is placed at post condenser loop

outlet and passes liquefied refrigerant to

capillary.

Desiccant (20) 8 x 12 4AXH - 7 M>S> -

Grams

Drier must be changed every time the system is opened for testing or

compressor replacement.

NOTE:

Drier used in R12 sealed system is not interchangeable with

drier used in R134a sealed system. Always replace the drier with Amana

part number B2150504.

Before openin

refri

eration s

stem, recover HFC134a refri

erant for safe

disposal.

Cut drier out of system using the following procedure. Do not unbraze drier.

Applying heat to remove drier will drive moisture into the system.

1. Score capillary tube close to drier and break.

2. Reform inlet tube to drier allowing enough space for large tube cutter.

3. Cut circumference of drier 1 ¼

″

below condenser inlet tube joint to drier.

4. Remove drier.

5. Apply heat trap paste on post condenser tubes to protect grommets from

high heat.

6. Unbraze remaining part of drier. Remove drier from system.

7. Discard drier in safe place. Do not leave drier with customer. If refri

erator is

under warranty, old drier must accompany warranty claim.

Evaporator Inner volume of evaporator allows

liquefied refrigerant discharged from

capillary to expand into refrigerant gas.

Expansion cools evaporate tube and fin

temperature to approximately -29

°

C

(-20

°

F) transferring heat from freezer

section to refrigerant.

Passing through suction line to

compressor, the refrigerant picks up

superheat (a relationship between

pressure and temperature that assures

complete vaporization of liquid

refrigerant) as result of capillary in

suction line.

Refrigerant gas is pulled through suction

line by compressor to complete the

refrigerant cycle.

Test for leaks in evaporator with electronic leak detector or with soap solution.

Compressor oil is circulated with refrigerant; check for oil when checking for

leaks.

For minute leaks

1. Separate evaporator from rest of refrigeration system and pressurize

condenser up to a maximum of 9.65 bars (140 PSI) with a refrigerant and

dry nitrogen combination.

2. Recheck for leaks.

CAUTION

To avoid death or severe personal injury, cut drier at correct location.

Cutting drier at incorrect location will allow desiccant beads to scatter. If

spilled, completely clean area of beads.

00

5

10

15

20

25

30

35

40

45

50

55

Loading...

Loading...