8

IOM (Safety) - Installation, Operation and Maintenance

Optical Oxygen Analyzer

Additional Options for Product Model Selection (Table 2)

* Sensor Style - Selection “X” can be: Sxyz, where xyz is equal to ber length in meters (e.g. S025, S050)

** Mounting Orientation - Selection “Y” can be either “L” or “R”

2�4 OXYvisor Accessories

Table 3 - OXYvisor

Part Number Description

B5008-1125 Pipe Mount Kit - 316 SS (1 to 1.5” pipe) - Included with OXYvisor (standard)

B4951-1140 Plug 3/4” MNPT Aluminum Zone 1&2

B4951-1141 Plug M25 Aluminum Zone 1&2

B4951-1142 Plug 3/4” MNPT CI D1&2

The OXYvisor analyzer uses a quench uorescence technique with a sensor optically isolated from the process, using the absorbency as a

diagnostic function and analyzing the phase angle for measurement of the analyte, oxygen, in the modulated time domain. This gives the analyzer the

ability to measure accurately and precisely under various and changing ambient and process conditions.

The resulting measurement is specic to oxygen concentration. The luminophore is unaected by other constituent gases and ow rate. The

measurement is applicable in both gas and liquid phase. Temperature compensation is required to account for quenching eciency at dierent

temperatures and pressure compensation is required to measure at process pressured dierent than the pressure at time of calibration.

2.5 General principle of operaon

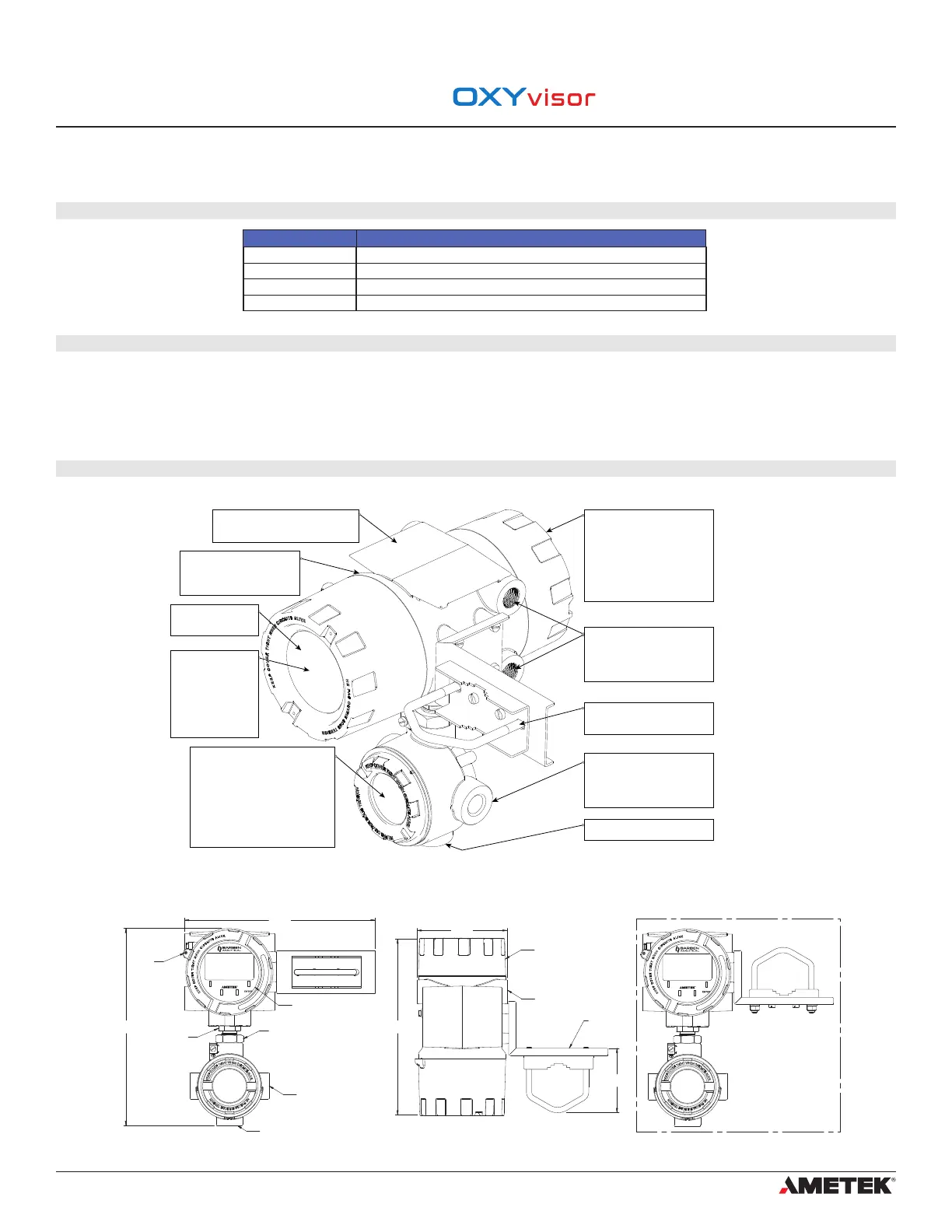

OXYvisor Analyzer Overview

Figure 1 - OXYvisor overview of hardware features

2�6 OXYvisor Analyzer Features (Hardware/Firmware/Soware)

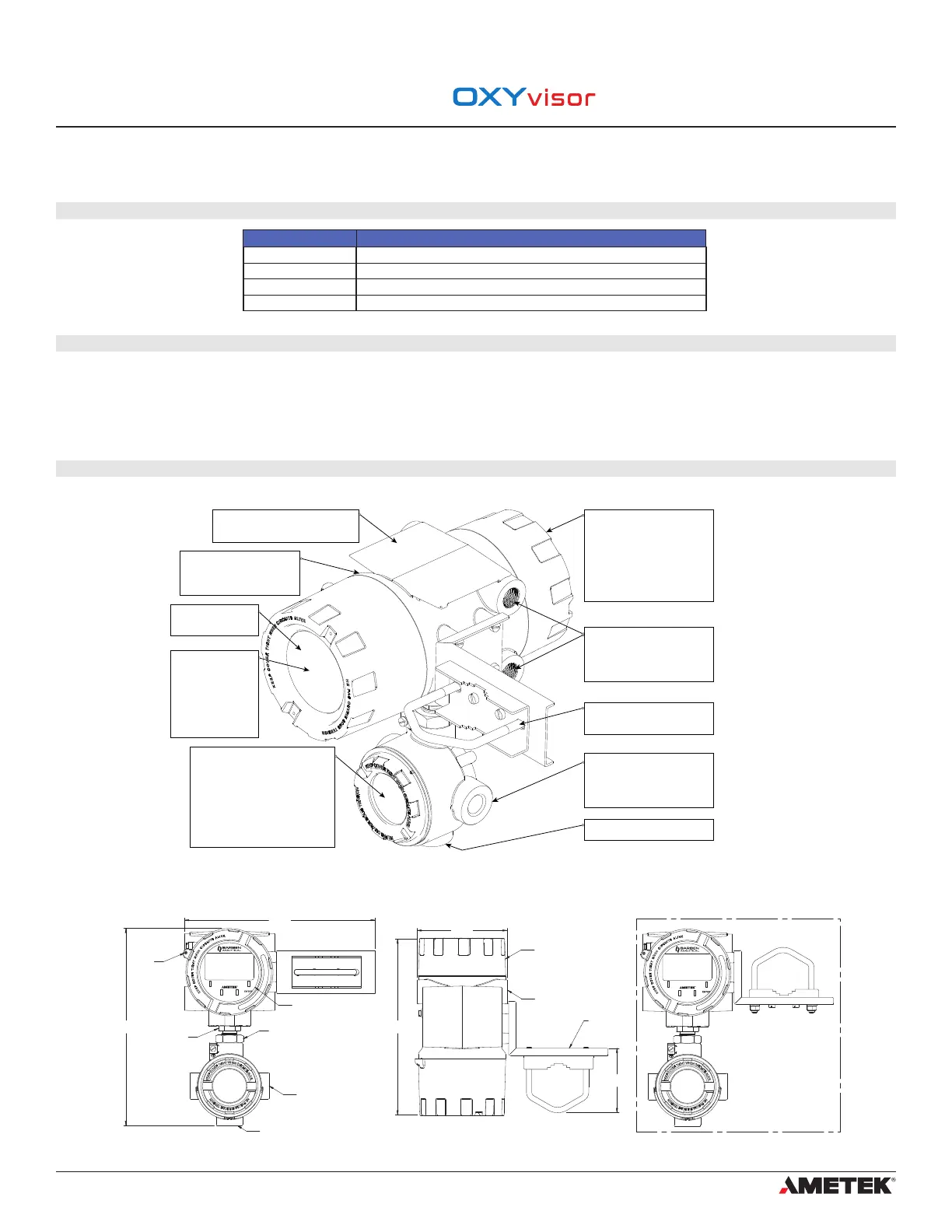

OXYvisor Analyzer Dimensions

Figure 2 - OXYvisor Overall Dimensions

11.4"

288mm

DISPLAY AND THROUGH-

THE-GLASS TOUCH

KEYPAD

3/4" FNPT (X2)

or M25 x 1.5 6H

conduit entries

1/2" FNPT (X1)

11.7"

298mm

FIBER OPTIC

BUSHING

P/N B3907-1SFP

or B3907-2SFP

JAM NUT

(FOR J-BOX ROTATION)

2 mm

Hex Lock

ESC

OXYvisor

5.4"

136mm

10.5"

266mm

REAR WIRING

COMPARTMENT

2” MOUNT

BRACKET

B5008-1125

3.8"

97mm

ALTERNATE MOUNT STYLE

HORIZONTAL PIPE

ESC

OXYvisor

3/4" NPT (X4)

or M25 x 1.5 6H

conduit entries

FRONT VIEW TOP VIEW

FRONT VIEW

(ALTERNATE MOUNT)

Rear (Wiring) Compartment

Contains the connection

terminals for power and all I/O’s

except oxygen sensor. The cap

(cover) is threaded, sealed via

O-ring and secured with a set

screw. The features allow easy,

but controlled, access to wiring

terminals.

Conduit Entries

There are four 3/4” FNPT or

M25x1.5 6H conduit entries

(size selected during ordering)

for the Rear (Wiring) Compartment.

Conduit Entries (Junction Box)

There are two 3/4” FNPT or

M25x1.5 6H conduit entries

(size selected during ordering)

for the Junction Box

Nameplate / Label

Contains the part number, company

info, and the Hazardous Area Markings.

Pipe Mount Bracket

316 SS, 2” Pipe / Field Mounting

Bracket.

Oxygen Sensor Entry

1/2” FNPT for the Oxygen sensor

Flameproof glass (Ex d)

Protects the HMI, LCD

and other electronics.

Human Machine Interface

The HMI, located

behind the flameproof

glass, includes backlit

LCD and Through-the-

glass keypad for user

configuration and full

interactive use.

Junction Box

Contains easily accesible sensor

connection(s).

All analyzer models

SMA connector for optical O2 sensor

or optical fiber wand assembly.

All analyzer models except Zone 1

Molex connector for Pt1000 RTD

Rugged Industrial Enclosure

IP66 / NEMA4x, pressure die-

casting with yellow chromating

and chemically resistant paint.

Section 2

Technical Product Specication

Loading...

Loading...