AMSAFE SEATBELT AIRBAG SYSTEM

INSTALLATION, HANDLING & SHIPPING INSTRUCTIONS E510629

SHIPPING, TRANSPORTATION, HANDLING, STORAGE PROCEDURES

02-Aug-2013

Page 4006

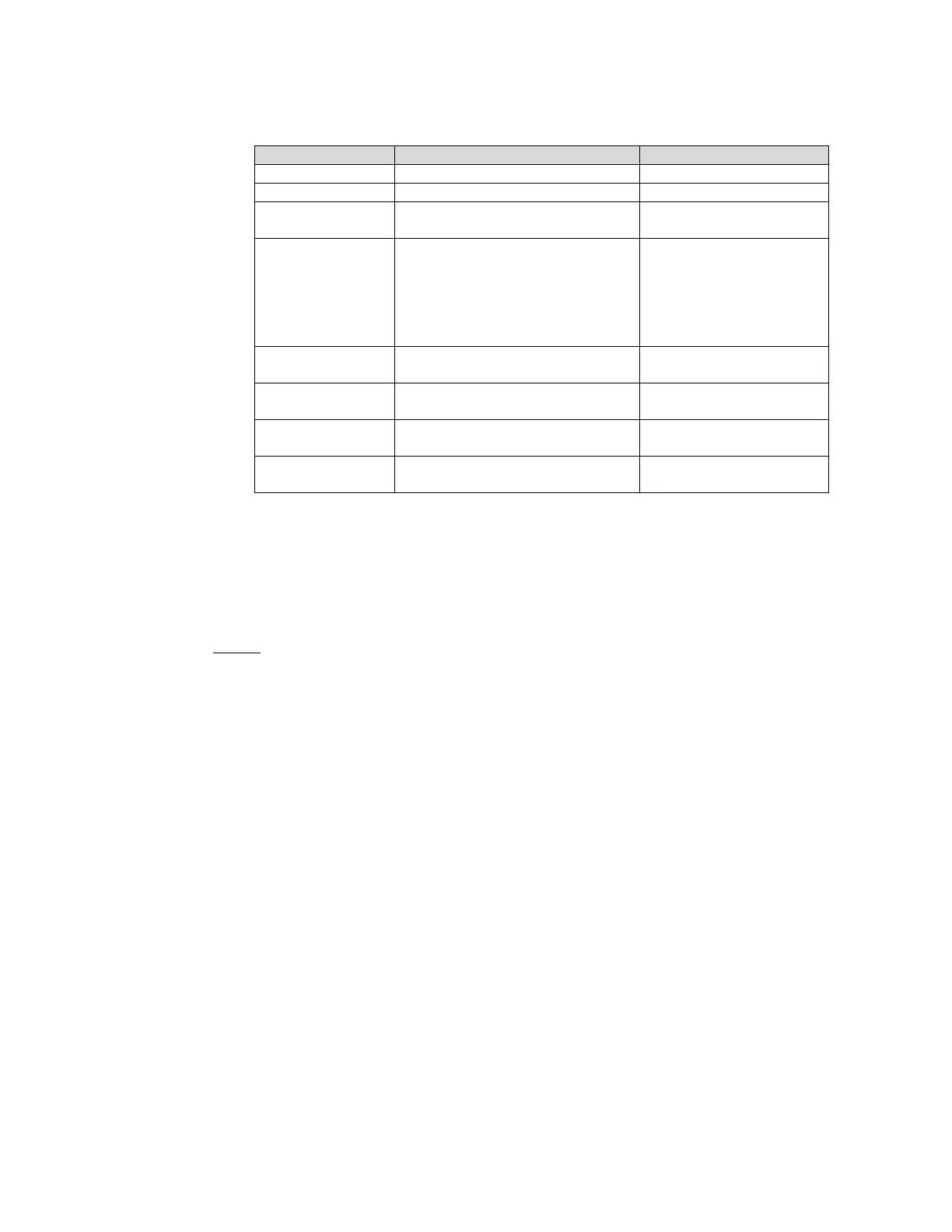

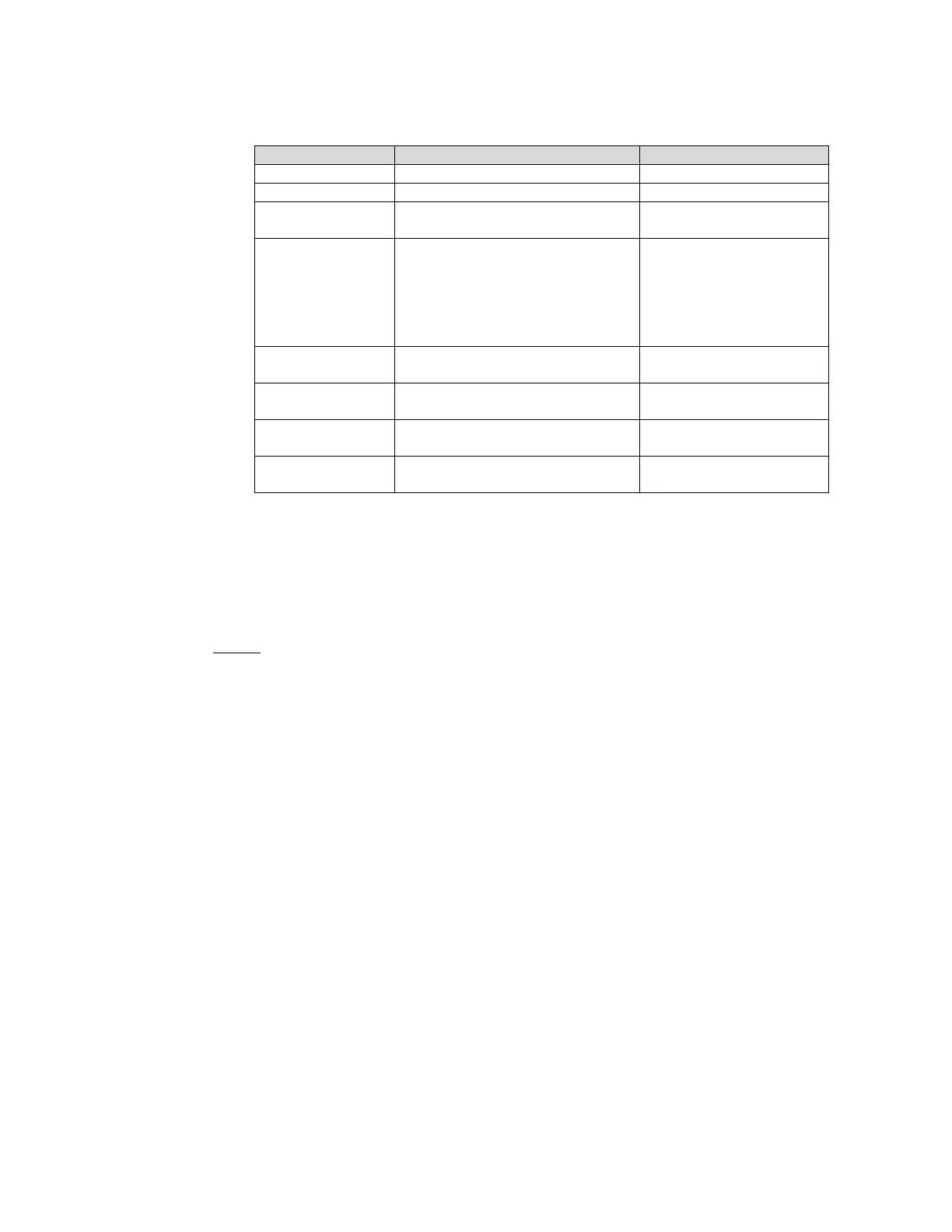

INFLATOR P/N DESCRIPTION EX NUMBER

508793-401 TRW, ROI-V2, 3.1 MOLE EX2007020371

510226-401 Autoliv, ASH 2.2 EX2000020021

510184-401

510183-401

Autoliv, ACH 2 to 2.2 Family EX2009080441

511077-401

511450-401

511452-401

511454-401

511456-401

511878-401

Autoliv, ACH 2.3 to 2.5 Family EX2009080443

511482-401 ARC, ADC-58, 1.20 Mole (from

Morgantown, KY)

EX2011121271

511482-401

ARC, ADC-58, 1.20 Mole (from

Reynosa, Mexico)

EX2009080150

511482-401 ARC, ADC-58, 1.20 Mole (from

Xi’an, China)

EX2008050101

511482-401 ARC, ADC-58, 1.20 Mole (from

Knoxville, TN)

EX2000060075

(e) Material Safety Data Sheets for all inflator assemblies can be found at the end of this

document. Contact Shipping Department any questions regarding shipping @

shipping@amsafe.com or (602) 850-2768.

G. Packaging and Shipping Requirements – AmSafe Seatbelt Airbag Components except the Inflator

NOTE:

FOR REGULATED MATERIALS TRANSPORTATION – COMPLIANCE WITH

APPLICABLE TRANSPORTATION REQUIREMENTS IS STRICTLY THE

RESPONSIBILITY OF THE END USER AND NOT OF AMSAFE.

(1) Use the packaging material in which the AmSafe Seatbelt Airbag System was received, if

available and when it is in a serviceable condition. If not serviceable, new materials of the

same quality and size shall be used.

(2) Cushioning

(a) “Peanut” type foam materials shall not be used for packaging AmSafe Seatbelt Airbag

System components. Peanut-shaped foam can migrate in the container, causing the item

to shift to the container side and be subject to shipping and handling damage.

(b) Use a minimum of three inches of cushioning material to prevent movement of the item

within the container.

(3) External Packaging

(a) Shipping container shall be of same quality, type, and size as unit shipped new.

Loading...

Loading...