Amtech

Chapter-3: Initial Start-

The VT24

0S has various setting items. Some of these include

the power supply and motor before actually starting

The methods for the VT240S basic test operation and

3-1 Selection of Control M

With the VT240S, four control modes a

parameter C30-

0 (control mode selection).

* C30-0 is set with a 2-digit value (

(1) Control modes

Refer to the following table, and select the

Normal-duty

1) V/f control

2) IM sensor-less

vector control

3) IM close loop

vector control

4) PM

loop control

Heavy-duty

1) V/f control

2) IM sensor-less

vector control

3) IM close loop

vector control

4) PM motor

loop control

Normal-duty setting:

Select this when the maximum load rate in respect t

The overload standard will be 120% of the device's

Heavy-duty setting:

Select this when the maximum load rate in res

The overload standard will be 150% of the device's

3-

2 Initialization of motor constants

Input the motor rating parameters.

0S has various setting items. Some of these include settings

that must be made according to

the power supply and motor before actually starting operation.

The methods for the VT240S basic test operation and adjustment are explained in this section.

With the VT240S, four control modes a

nd two overload modes can be selected. These are se

0 (control mode selection).

, f0).

Refer to the following table, and select the

mode, which suits the application.

The IM

is controlled keeping the ratio of voltage and

frequency constant.

The IM is vector-

controlled without a speed sensor.

The speed can be controlled.

PLEASE REFER FULL INSTRUCTION MANUAL

PLEASE REFER FULL INSTRUCTION MANUAL

The IM

is controlled keeping the ratio of voltage and

frequency constant.

The IM is vector-

controlled without a speed sensor.

The speed can be controlled.

PLEASE REFER FULL INSTRUCTION MANUAL

PLEASE REFER FULL INSTRUCTION

Select this when the maximum load rate in respect to the rated load is low.

The overload standard will be 120% of the device's rated current for one minute.

Select this when the maximum load rate in res

pect to the rated load is high.

The overload standard will be 150% of the device's rated current for one minute.

2 Initialization of motor constants

Input the motor rating parameters.

Set the parameters shown in Table 4-2-1.

automatically change the parameters, so it is

recommended to write down the values set

in Table 4-2-2 or Table 4-2-3.

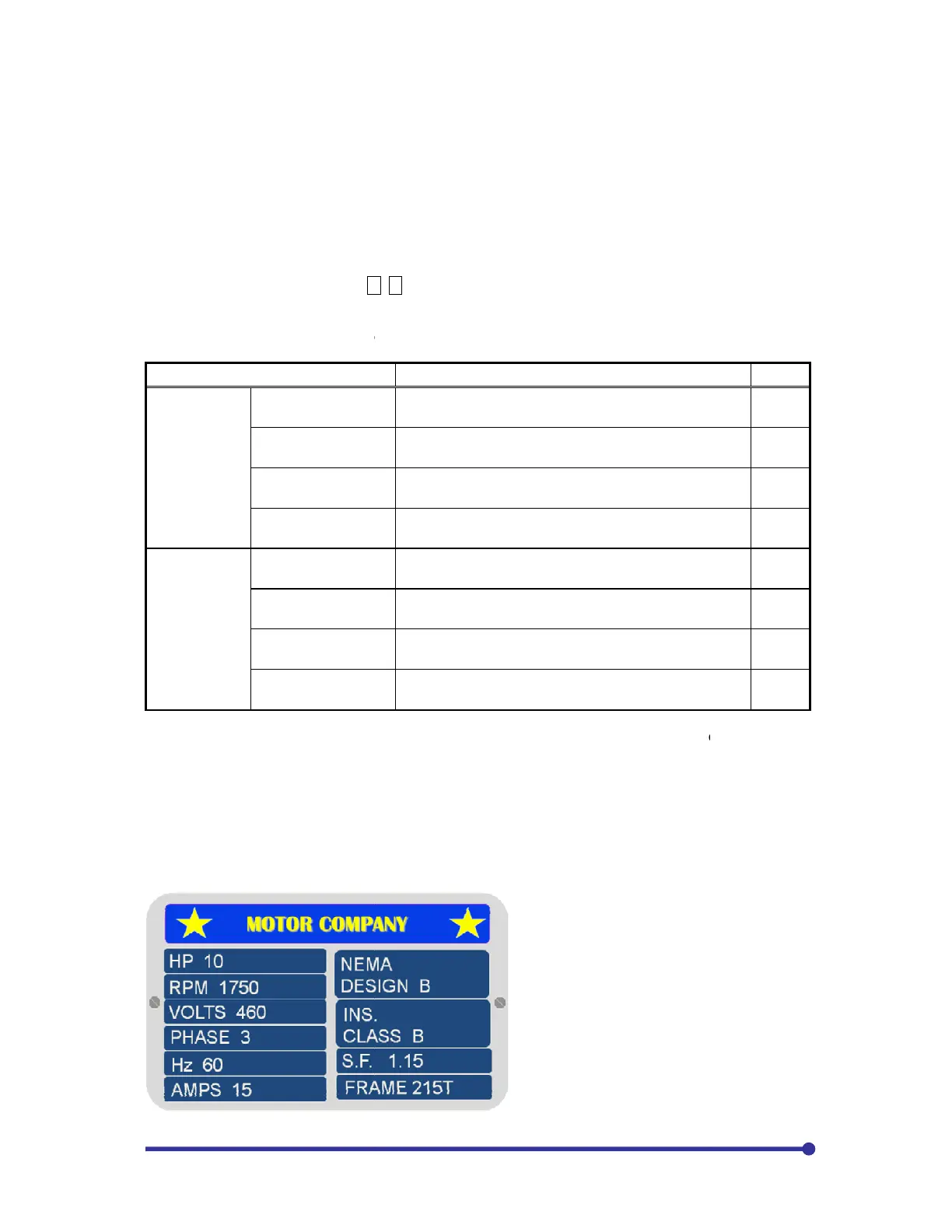

The figure to the left shows the information

provided on a typical AC motor nameplate.

There are several important m

that will be used to program the drive to

provide accurate motor operation and

protection. The motor HP will be

programmed in KW. To change from HP to

KW, multiply by 0.75. The 10HP shown

would be 10 x 0.75 = 7.5KW. For this case

motor, assumin

g the input voltage >460,

B00-0=6, B00-1=2, B00-

that must be made according to

adjustment are explained in this section.

nd two overload modes can be selected. These are set with the

is controlled keeping the ratio of voltage and

11

controlled without a speed sensor.

12

PLEASE REFER FULL INSTRUCTION MANUAL

13

PLEASE REFER FULL INSTRUCTION MANUAL

14

is controlled keeping the ratio of voltage and

21

controlled without a speed sensor.

22

PLEASE REFER FULL INSTRUCTION MANUAL

23

24

pect to the rated load is high.

automatically change the parameters, so it is

recommended to write down the values set

The figure to the left shows the information

provided on a typical AC motor nameplate.

There are several important m

otor values

that will be used to program the drive to

provide accurate motor operation and

protection. The motor HP will be

programmed in KW. To change from HP to

KW, multiply by 0.75. The 10HP shown

would be 10 x 0.75 = 7.5KW. For this case

g the input voltage >460,

-3=460,

Loading...

Loading...