Copyright by Servizio Clienti ANGELO PO Spa

119

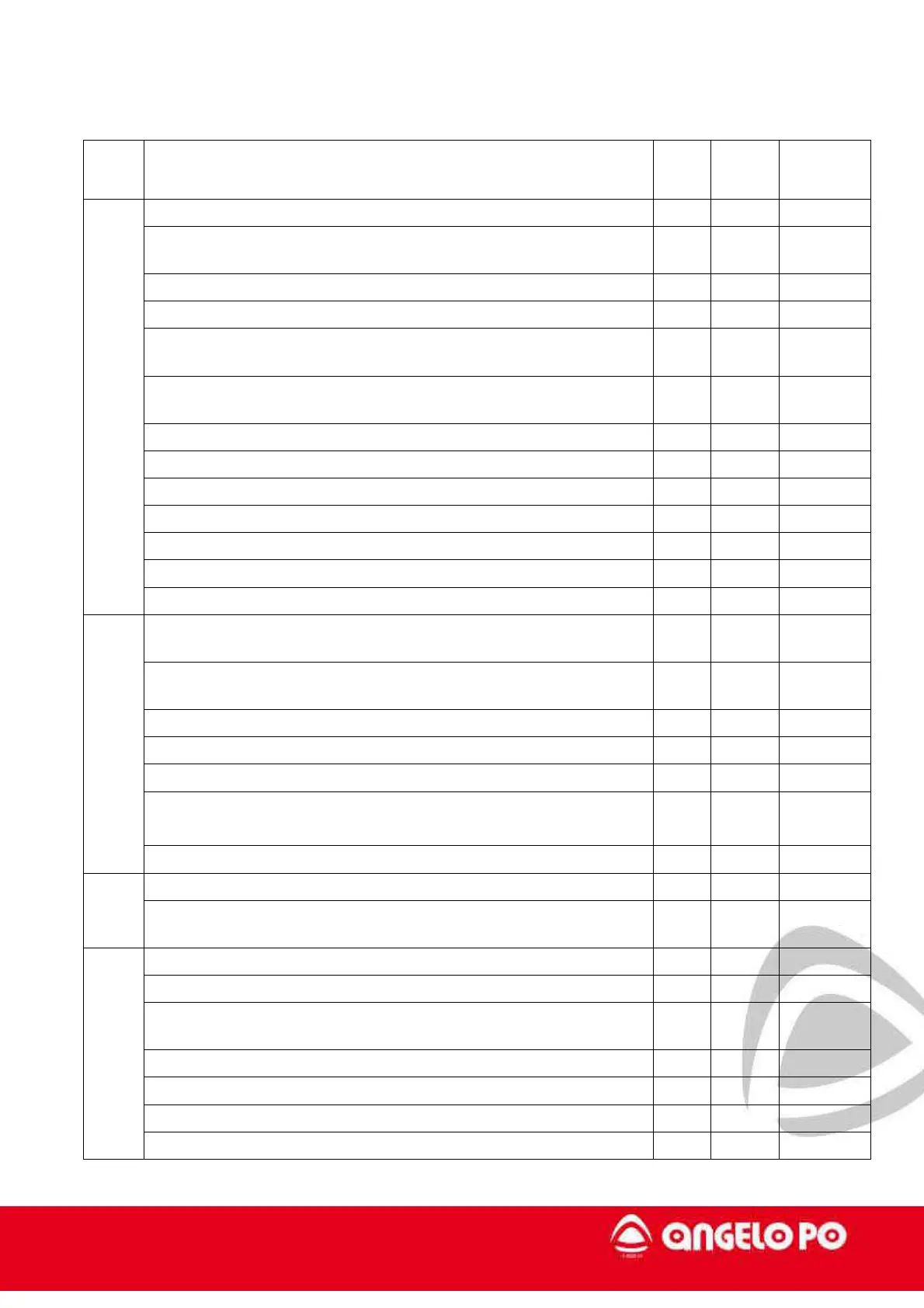

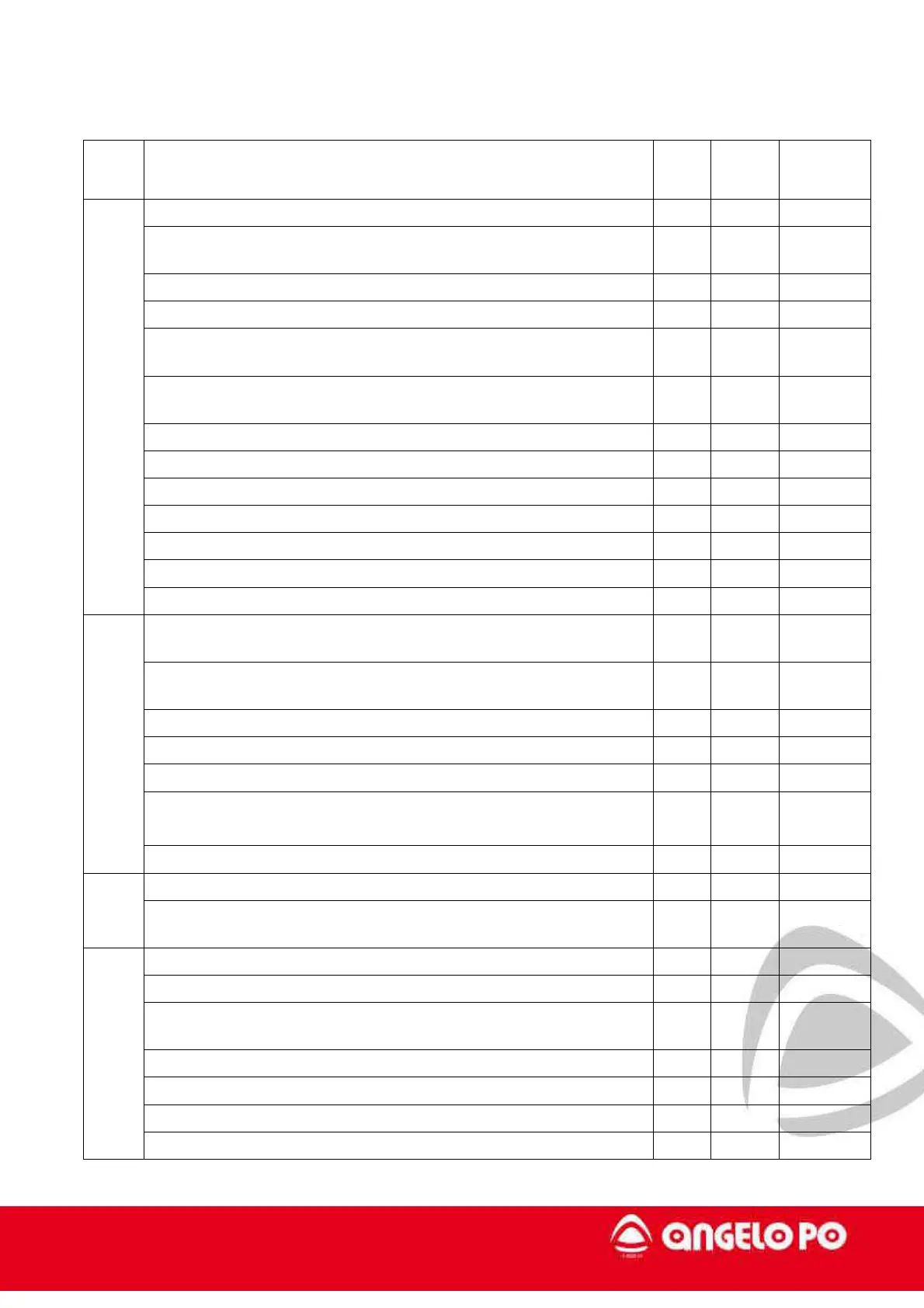

7.17. Scheduled recommended maintenance

Yearly

Every

two

years

Chapter/

Paragraph

Cleaning air intakes X 7.5

Open the dashboard and replace the seal – clean and check possible

steam leakage

X 7.14

Check components compartment cooling fans working X 7.5

Check motorized valve status and working X 2 pic.7

Check core probe status and working (where present) X 7.7

Check door gasket and steam leakage during cooking. X 7.14

Visual check of the cooking chamber X

Check tightening of the fan fixing screw X 7.2

Check tightening, status and cleaning of the humidity probe X 7.8

cleaning siphon and drain lines X 2 pics14-15

cleaning of water intake filter X 2 pic.10

Check door adjustment X 7.6

All models

Check lamp gasket X 7.9

check incoming gas pressure and system tightness until gas valve X 4.2

Check and tightening gas system fixing screws (blower fan, gas inlet,

air-gas mixing inlet)

X 4.2.2

Cleaning combustion air intake (filter underneath the oven) X 7.5

Check and cleaning gas valve air intake X 7.5

Check CO and CO2 performing gas flue analyzes X 4.11

Spark plug and gasket replacement and wires check

X

(LPG)

X

(Natural

gas)

7.12

Gas models only

Visual check of heat exchanger gasket X

Check resistance cables tightening X

Electric

only

Check resistance gasket seal and screws tightening X

Check alarms list in the menu service X 3.2

Replace the pipes in the peristaltic pumps X

Run pump test procedure – check the pumps working X 5.2

Check possible leaks on the fittings of the pumps X 5.2

Check and possible adjustment rinse water pressure X 5.2

Disassemble multi-injector sprinkler and check possible obstructions X 5.2

Level 3 only

Clean inverter air intakes X 3.4

Loading...

Loading...