6

1.1 Thermal Ink Jet (TIJ) Technology

TIJ technology uses a drop ejection process, storing ink in a cartridge that regulates the

pressure of the fluid. Inks are then delivered to the firing chamber to be heated at more

than 1,000,000 C/second by an electric resister. A 0.1 micrometer thick film of ink is heated

to around 340C, from which a bubble is formed to expel the ink. A droplet breaks away

from this bubble causing it to collapse, the firing chamber then refills as the whole process

repeats.

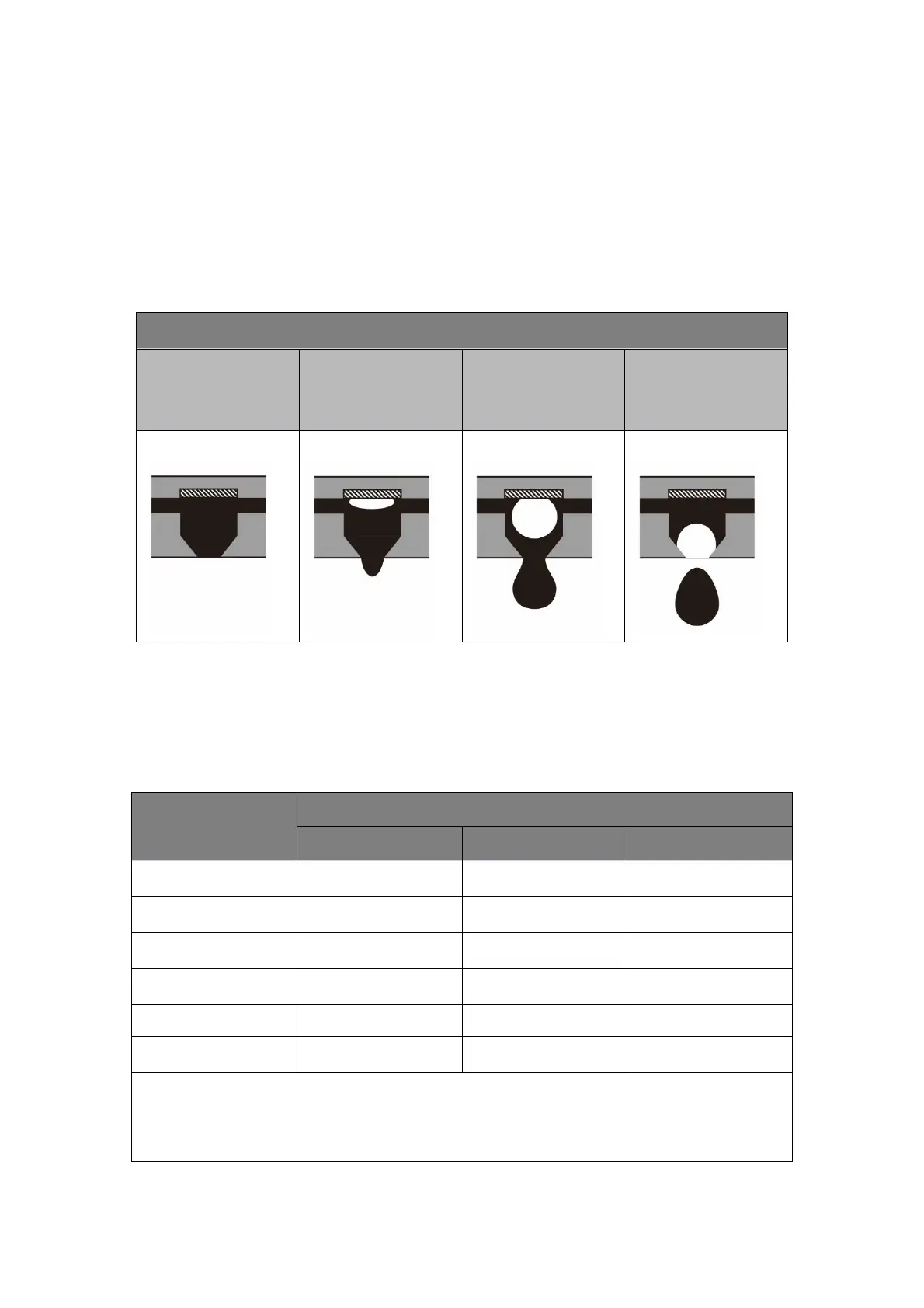

Ink vaporization

generates a bubble

Bubble forces ink

out of the nozzle

Bubble collapse

causing the droplet

breakoff

1.2 ANSER TIJ inkjet printer portfolio

ANSER provide wide range of TIJ printing solution suitable for your ever-increasing

coding demand….

* Substrate classification

Porous: Paper, cardboard, sponge, untreated woods, etc.

Semi Porous: Waxed surfaces, coated paper, plaster, concrete, etc.

Non Porous: plastics, metals, varnished woods, glass, etc.

Loading...

Loading...