5.2.2 Clean and activate ORP electrode

After the electrode has been used over a long period of time, the platinum surface will get polluted which

causes inaccurate measurement and slow response. Please refer to the following methods to clean and

activate ORP electrode:

(a) For inorganic pollutant, soak the electrode in 0.1mol/L dilute hydrochloric acid for 30 minutes, then

wash it in distilled water, then soak it in the 3M KCL storage solution for 6 hours.

(b) For organic or lipid pollutant, clean the platinum surface with detergent, then wash it in distilled water,

then soak it in the 3M KCL storage solution for 6 hours.

(c) For heavily polluted platinum surface on which there is oxidation film, polish the platinum surface with

toothpaste, then wash it in distilled water, then soak it in the 3M KCL storage solution for 6 hours.

6 CONDUCTIVITY MEASUREMENT

6.1 Information regarding the Conductivity Electrode

6.1.1 Conductivity electrode

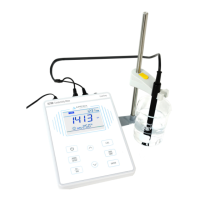

Model 2301T-S plastic conductivity electrode with constant K=1.0 and built-in temperature sensor, can

realize automatic temperature compensation. The electrode housing is POM plastic which is corrosion

resistant and impact resistant. When dipping the conductivity electrode in solution, stir the solution briefly

to eliminate the air bubbles and improve response and stability.

6.1.2 Conductivity electrode constant

The meter matches conductivity electrodes of three constants: K=0.1, K=1.0 and K=10.0. Please refer to

table-7 for measuring range. Set constant in parameter setting P2.1 and refer to section 7.4

Table– 7 Electrode constant and measuring range

Note: When testing ultra-pure water with conductivity less than 1.0 μS/cm, a flow test should be conducted

in a flow cell.

6.1.3 When connecting the electrode, please rotate slowly to identify the location of the mount before

plugging in. The nut on the connector should be screwed on tightly. Once the conductivity electrode is

Loading...

Loading...