Ascon Tecnologic - K31D - OPERATING INSTRUCTIONS - PAG. 6

Again in the ]PAn group is present the parameter AdE that

defines the 3 LEDs shift index ( ) functioning.

The lighting up of the green LED (=) indicates that the

process value is within the range [SP + AdE÷SP - AdE], the

lighting up of the LED (-) indicates that the process value

is lower than [SP - AdE] and the lighting up of the LED (+)

indicates that the process value is higher than [SP + AdE].

5.2 Output Configuration

The instrument outputs can be programmed by entering the

group of parameters ]Out, where the relative parameters

o1F, o2F, o3F and o4F (depending on the number of out-

puts available on the instrument) are located.

The outputs can be set for the following functions:

1.rEG Main control output;

2.rEG Secondary control output;

ALno Alarm output normally open (NO);

ALnc Alarm output normally closed (NC);

ALni

Alarm output

NC

with LED reverse indication;

oFF Output deactivated.

The coupling between output-number – alarm-number can

be made in each alarm group referred to each alarm (]AL1,

]AL2 or ]AL3).

If the instrument has an analogue control output, the type of

output can be selected using the Aot parameter in the group]

InP with the following possibilities:

0-20 0

÷

20 mA;

4-20 4

÷

20 mA;

0-10 0

÷

10 V;

2-10 2

÷

10 V.

5.3 Absolute or Differential Temperature

Controller

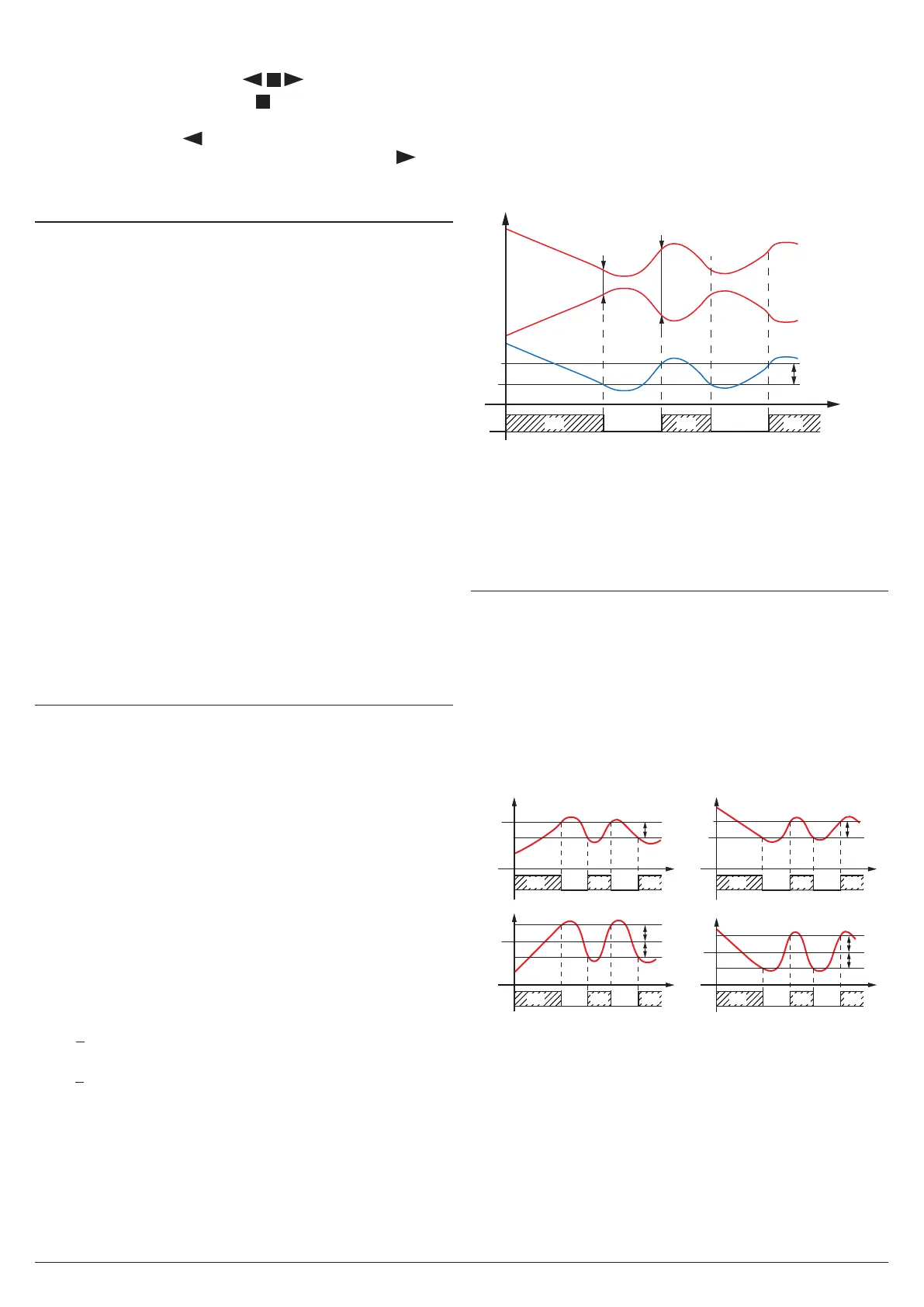

Through the PrrG parameter it is possible to set the process

variable used by the controller to operate.

In fact the controller can operate considering the process

variable as the value measured at Input 1 (Pr1), the value

measured at Input 2 (Pr2), the difference between the two

inputs Pr1-Pr2 (P1-2) or can consider the difference be-

tween the two inputs Pr1-Pr2 but with a maximum limit and a

minimum limit for the Pr2 measurement (P1-L).

The choices PrrG = P1-2 or = P1-L make the controller

operate as a differential controller.

In these cases the controller acts on the control outputs so it

keeps the difference Pr1-Pr2 equal to the Set Point value.

The difference between the two modes lies in the fact that

the P1-L mode activates a limit in the controller in terms of

the calculation of the temperature difference according to the

P2HL and P2LL parameters (both in the ]SP group) so that:

If Pr2 > P2HL the process value considered by the controller is

[Pr1-P2HL]

If Pr2 < P2HL the process value considered by the controller is

[Pr1-P2LL]

When P2HL and P2LL thresholds are exceeded by Pr2 tem-

perature, a control takes place as if the Pr2 temperature is

the value of the limit regardless of the value actually read.

The aim of this function is to limit the differential regulation to

within a maximum range of the Pr2 measurement.

With the differential control the working mode Func = CooL

is used for applications with which the action of the actuator

reduces the Pr1-Pr2 difference (thus countering the Pr1-Pr2

difference that naturally tends to increase).

Viceversa the Func = HEAt mode is used for applications

with which the action of the actuator increases the Pr1-Pr2

difference thus countering the Pr1-Pr2 difference that natu-

rally tends to decrease).

Obviously the Neutral Zone mode or the Double action

mode will set OFF both actions.

HSEt

Func = Cool

offoffoff

ON ON ON

Temp.

time

Pr1

Pr1- Pr2

Pr2

SP1

SP1 + HSEt

SP1

1.rEG

Example of differential ON/OFF control (On.FA) with

Func = CooL.

m

The controller is already programmed in production to

carry out differential regulation and display the tem-

perature difference Pr1 - Pr2.

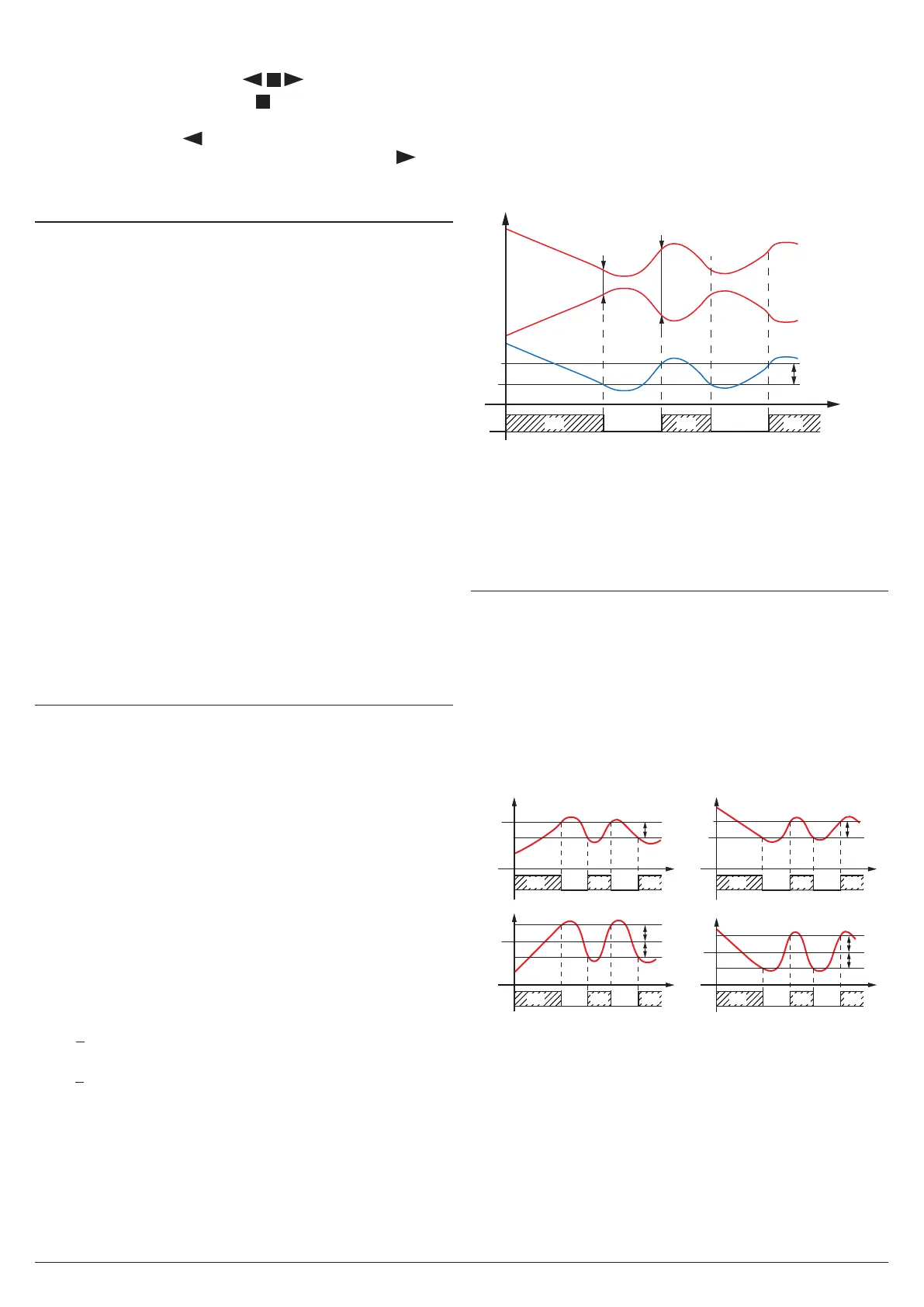

5.4 ON/OFF Control (1.rEG)

All the parameters referring to the ON/OFF control are con-

tained in the group ]rEG.

This type of control can be obtained by programming pa-

rameter Cont = On.FS or = On.FA and works on the output

programmed as 1.rEG, depending on the process value set

with PrrG, on the active Set Point SP, on the functioning

mode Func and on the hysteresis HSEt.

The instrument carries out an ON/OFF control with symmet-

ric hysteresis if Cont = On.FS or with asymmetrical hyster-

esis if Cont = On.Fa.

HEAt - on.FS

OUT

1.rEG

SP

PV

HSEt

HSEt

HEAt - on.FA

OUT

1.rEG

SP

PV

HSEt

time

off off

CooL

-

on.FS

OUT

1.rEG

SP

PV

HSEt

HSEt

Cool

-

on.FA

OUT

1.rEG

SP

PV

HSEt

time

time time

ON ON ON off offON ON ON

off offON ON ON off offON ON ON

The control works in the following way: in the case of reverse

action, or heating (FunC = HEAt), it deactivates the output,

when the process value reaches [SP + HSEt] in case of sym-

metrical hysteresis, or [SP] in case of asymmetrical hystere-

sis and is then activated again when the process value goes

below value [SP - HSEt].

Viceversa, in case of direct action, or cooling (Func = CooL),

it deactivates the output, when the process value reaches

[SP - HSEt] in case of symmetrical hysteresis, or [SP] in case

of asymmetrical hysteresis and is activated again when the

process value goes above value [SP + HSEt].

Loading...

Loading...