Ascon Tecnologic - K31D - OPERATING INSTRUCTIONS - PAG. 7

5.5 Neutral Zone ON/OFF Control (1.rEG - 2.rEG)

All the parameters referring to Neutral Zone ON/OFF control

are contained in the group ]rEG.

This type of control can be obtained when 2 outputs are pro-

grammed respectively as 1.rEG and 2.rEG and the parameter

Cont = nr.

The Neutral Zone control is used to control plants in which

there is an element which causes a positive increase (e.g.

Heater, humidifier, etc.) and an element which causes a

negative increase (e.g. Cooler, de-humidifier, etc.).

The control functions work on the programmed outputs de-

pending on the Process Value (PV), the active Set Point SP

and the HSEt hysteresis.

The control works in the following way: deactivates the out-

puts when the PV reaches the Set Point and it activates

the output 1.rEG when the PV goes below the [SP - HSEt]

value, or activates the output 2.rEG when the PV goes

above the [SP + HSEt] value.

Consequently, the element causing a positive increase

must be connected to the output programmed as 1.rEG

while the element causing a negative increase must be

connected to the output programmed as 2.rEG.

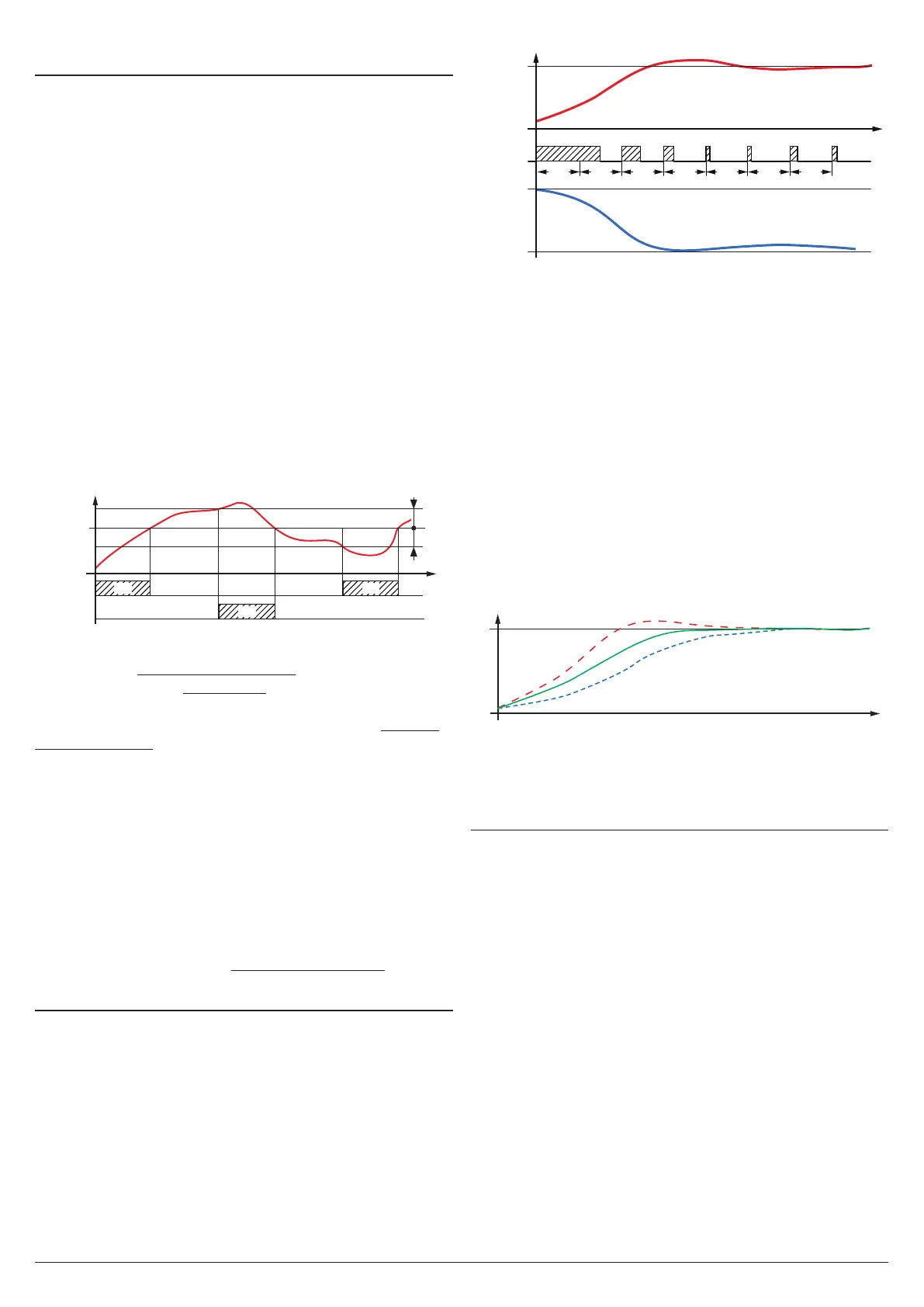

HSEt

HSEt

SP

PV

time

Out 1.rEG

(heating)

Out 2.rEG

(cooling)

offoff

off

ON

ON

ON

If 2.rEG output is used to control a compressor, it is possi-

ble to use the “Compressor Protection” function that is used

to avoid compressor “short cycles”. This function allows a

time control on 2.rEG output activation, regardless of the

temperature control requests. The protection is a “delayed

after deactivation” type.

This protection avoids the output activation for a time

programmable at parameter CPdt (in seconds); the output

activation occurs only after the CPdt time has elapsed.

The CPdt protection time count starts from the last 2.rEG

output deactivation.

Obviously, whether during the time delay caused by the com-

pressor protection function, the control request should stop, the

output activation foreseen after time CPdt would be erased.

The function is deactivated by programming CPdt = OFF.

The LED relative to 2.rEG output 2 blinks during the output ac-

tivation delay, caused by the “Compressor Protection” function.

5.6 Single Action PID Control (1.rEG)

All the parameters referring to PID control are in ]rEG group.

The Single Action PID control can be obtained by program-

ming parameter Cont = Pid and works on 1.rEG output depend-

ing on: the active Set Point SP, the functioning mode Func and

on the instrument PID algorithm with 2 freedom degrees.

If the Out1 analogue output is present (0/4 ÷ 20 mA; 0/2 ÷ 10 V)

the output will operate as a regulation output providing a

value proportional to the regulation power calculated by the

instrument.

PV

SP

100%

0%

time

ON ON ON ON ON ON ON

off off off off off off off

Digital

OUT1

1.rEG

(HEat)

Analogue

OUT1

1.rEG

(HEat)

tcr1tcr1 tcr1 tcr1 tcr1 tcr1 tcr1

In presence of fast processes, in order to obtain a good PV

stability, the tcr1 cycle time must have a low value with a

very frequent intervention of the control output. In this case

we recommend to use a Solid State Relay (SSR) for driving

the actuator.

The Single Action PID control algorithm foresees the setting of

the following parameters

:

Pb Proportional Band;

tcr1 Cycle time of 1.rEG output;

Int Integral Time;

rS Manual Reset (only if Int = 0);

dEr Derivative Time;

FuoC Fuzzy Overshoot Control.

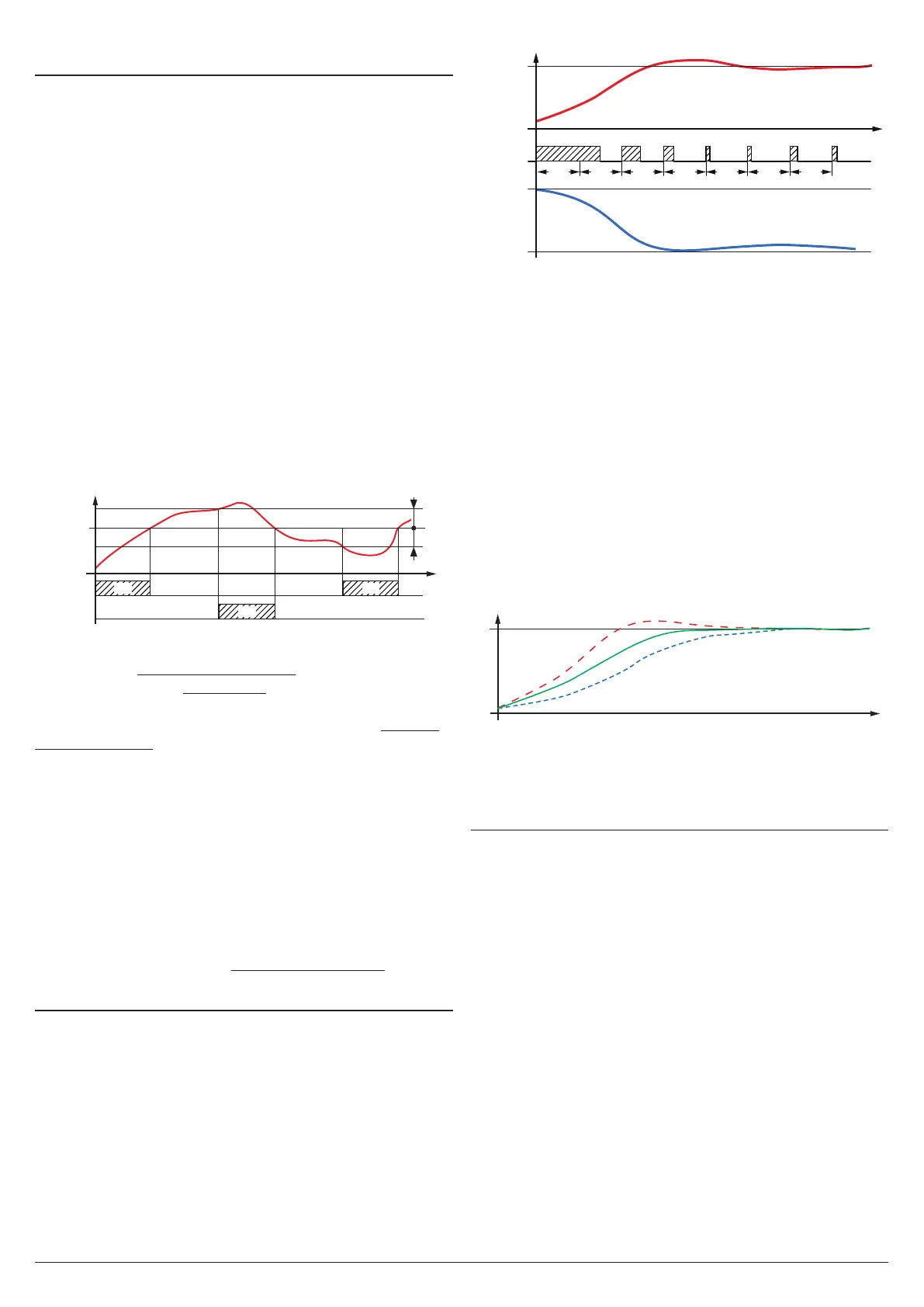

This last parameter allows the variable overshoots at the start up

of the process or at the changing of the Set Point to be avoided.

Please remember that a low value on this parameter reduces

the overshoot while a high value increase it.

PV

SP

time

1

3

1 FuoC Value OK;

2 FuoC Value too high;

3 FuoC Value too low.

5.7 Double Action PID Control (1.rEG - 2.rEG)

All the parameters referring to PID control are in ]rEG group.

Double Action PID control is used to control plants where

there is an element which causes a positive temperature in-

creases (ex. Heating) and an element which causes a nega-

tive temperature increases (ex. Cooling) and can be obtained

when 2 outputs are programmed respectively as 1.rEG and

2.rEG and setting Cont = Pid.

The element causing the positive increase must be con-

nected to the output programmed as 1.rEG while the element

causing the negative increase must be connected to the

output programmed as 2.rEG.

The Double Action PID control works on the outputs 1.rEG

and 2.rEG depending on the active Set Point SP and on the

instrument’s PID algorithm with 2 freedom degrees.

In presence of fast processes, in order to obtain a good Process

Variable stability, cycle times tcr1 and tcr2 must have a low

value with a very frequent intervention of the control outputs.

In this case we recommend to use Solid State Relays (SSR)

for driving the actuators.

Loading...

Loading...