Ascon Tecnologic - KX6 - ENGINEERING MANUAL - PAG. 12

]rEG group - Control parameters.

[39] cont - Control type:

Available: When at least one output is programmed as con-

trol output (H.rEG or C.rEG).

Range: • When two control actions (heat & cool) are pro-

grammed:

Pid PID (heat and cool);

nr

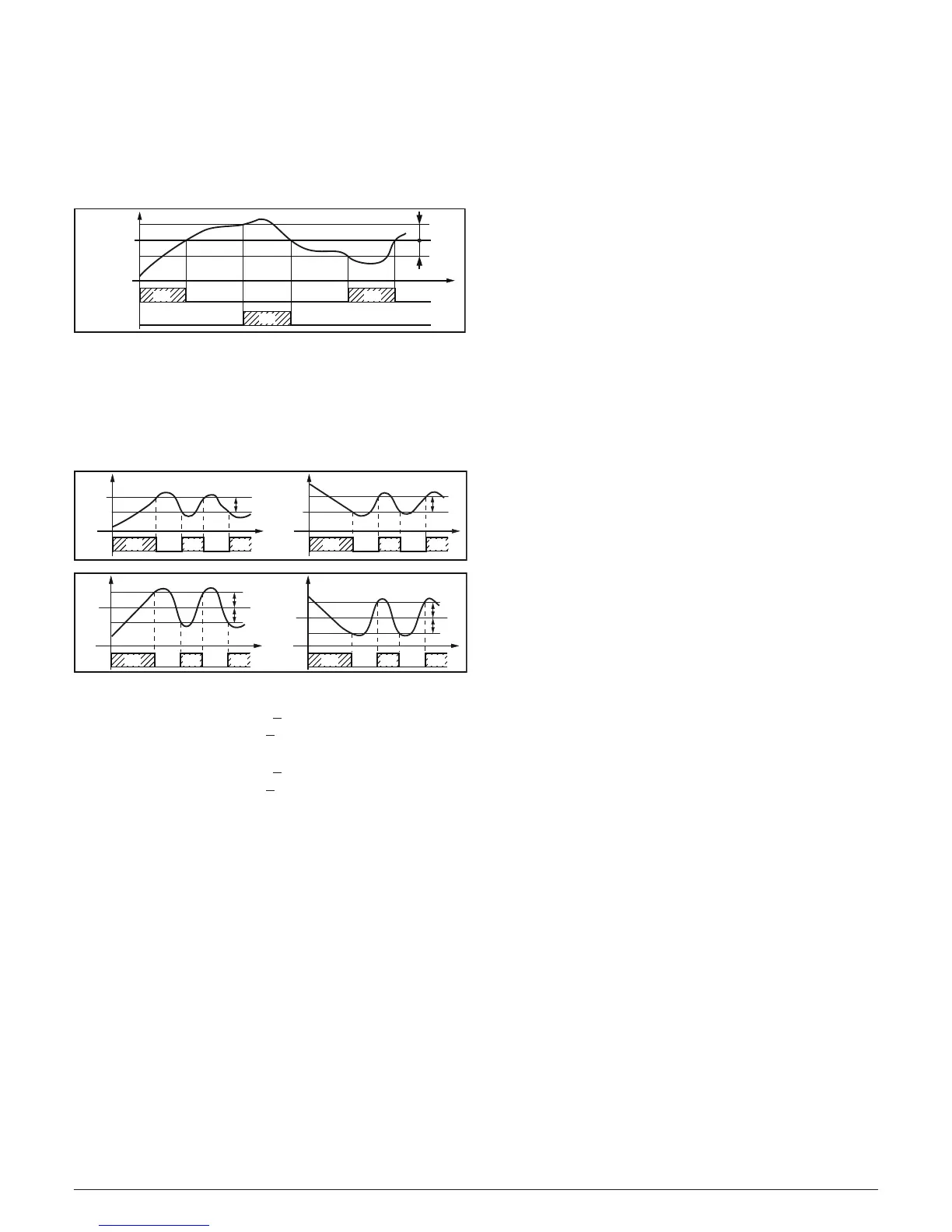

Heat/Cool ON/OFF control with neutral zone;

HSEt

HSEt

SP

PV

time

OUTH.rEG

(heating)

OUTc.rEG

(cooling)

offON ON

off off

ON

• When one control action (heat or cool) is pro-

grammed:

Pid PID (heat or cool);

On.FA ON/OFF asymmetric hysteresis;

On.FS ON/OFF symmetric hysteresis;

3Pt

Servomotor control (available when Out 1

and Out 2 have been ordered as “MM”).

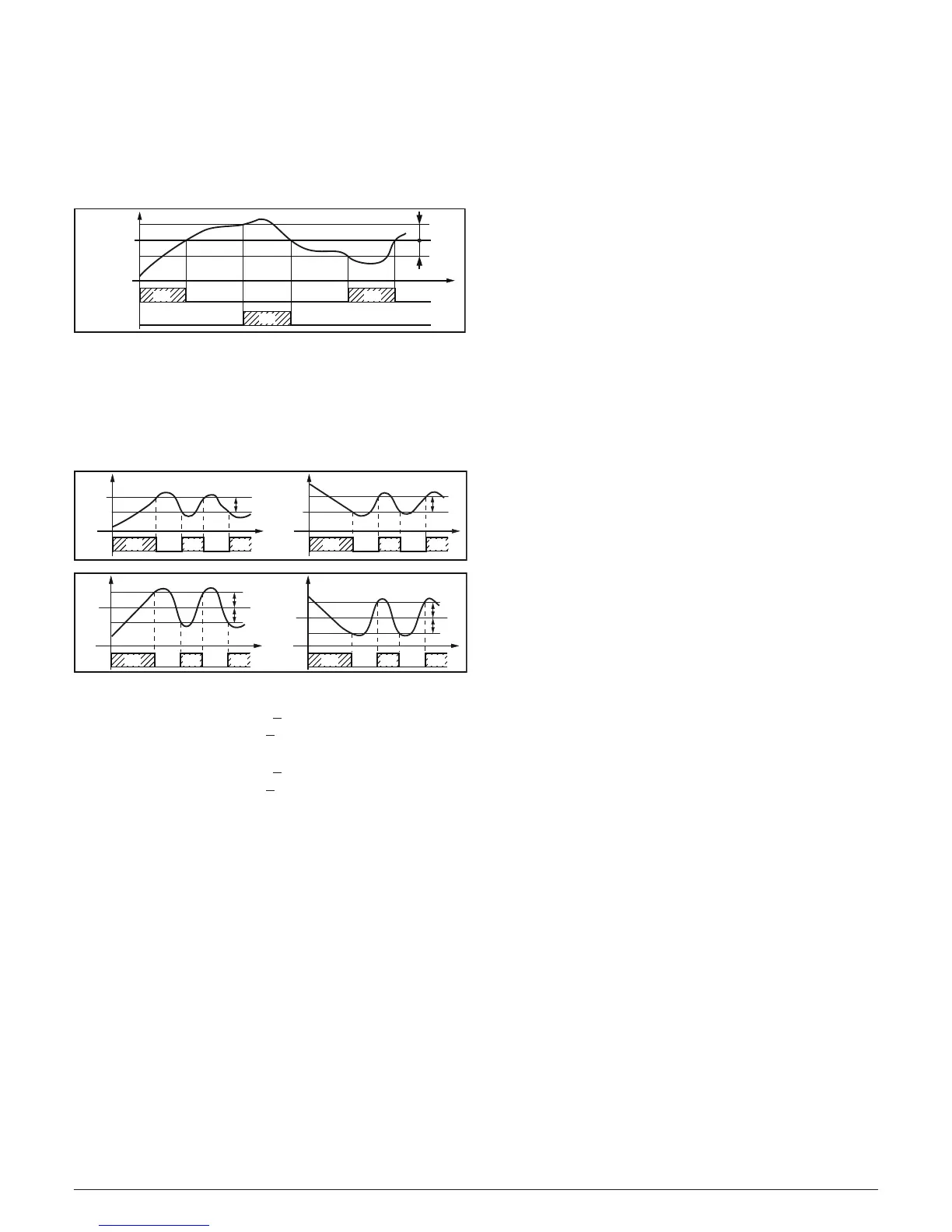

HEAt - On.FA

OUT

H.rEG

SP

PV

HSEt

time

off off

CooL-On.FA

OUT

C.rEG

SP

PV

HSEt

time

ON ON ON

off off

ON ON ON

HEAt - On.FS

SP

PV

HSEt

HSEt

time

CooL -On.FS

SP

PV

HSEt

HSEt

time

OUT

H.rEG

off off

OUT

C.rEG

ON ON ON off offON ON ON

Notes: 1. ON/OFF control with asymmetric hysteresis:

• OFF when PV > SP;

• ON when PV < (SP - hysteresis).

2. ON/OFF control with symmetric hysteresis:

• OFF when PV > (SP + hysteresis);

• ON when PV < (SP - hysteresis).

[40] Auto - Auto tune selection

Ascon Tecnologic has developed three auto-tune algorithms:

– Oscillating auto-tune;

– Fast auto-tune;

– EvoTune.

1. The oscillating auto-tune is the usual auto-tune and:

• It is more accurate;

• Can start even if PV is close to the set point;

• Can be used even if the set point is close to the

ambient temperature.

2. The fast type is suitable when:

• The process is very slow and you want to be opera-

tive in a short time;

• When an overshoot is not acceptable;

• In multi-loop machinery where the fast method reduces

the calculation error due to the effect of the other loops.

3. The EvoTune type is suitable when:

• You have no information about your process;

• You can not be sure about the end user skills;

• You desire an auto tune calculation independently

from the starting conditions (e.g. set point change

during tune execution, etc).

Note: Fast auto-tune can start only when the measured

value (PV) is lower than (SP + 1/2 SP).

Available: When [39] cont = PID or 3Pt.

Range: -4... 8 where:

-4 Oscillating auto-tune with automatic restart at

all set point change;

-3 Oscillating auto-tune with manual start;

-2 Oscillating auto-tune with automatic start at the

first power up only;

-1 Oscillating auto-tune with automatic restart at

every power up;

0 Not used;

1 Fast auto tuning with automatic restart at every

power up;

2 Fast auto-tune with automatic start at the first

power up only;

3 FAST auto-tune with manual start;

4 FAST auto-tune with automatic restart at all set

point change.

5

EvoTune with automatic restart at every power up;

6 EvoTune with automatic start at the first power

up only;

7 EvoTune with manual start;

8 EvoTune with automatic restart at all set point

change.

[41] tunE - Manual start of the auto-tune

Available: When [39] cont = PID or 3Pt.

Range: oFF

The instrument is not performing the auto-tune;

on The instrument is performing the auto-tune.

[42] HSEt - Hysteresis of the ON/OFF control

Available: When [39] cont is different from PID or 3Pt.

Range: 0... 9999 engineering units.

[43] Pb - Proportional band

Available: When [39] cont = PID or 3Pt.

Range: 1... 9999 engineering units.

Note: Auto-tune functions calculate this value.

[44] ti - Integral time

Available: When [39] cont = PID or 3Pt.

Range: OFF = Integral action excluded;

1... 9999 seconds;

inF= Integral action excluded (reserved).

Note: Auto-tune functions calculate this value.

[45] td - Derivative time

Available: When [39] cont = PID or 3Pt.

Range: oFF - derivative action excluded;

1... 9999 seconds.

Note: Auto-tune functions calculate this value.

[46] Fuoc - Fuzzy overshoot control

This parameter reduces the overshoot usually present at

instrument start up or after a set point change and it will be

active only in this two cases.

Setting a value between 0.00 and 1.00 it is possible to slow

down the instrument action during set point approach.

Setting Fuoc = 1 this function is disabled.

Loading...

Loading...