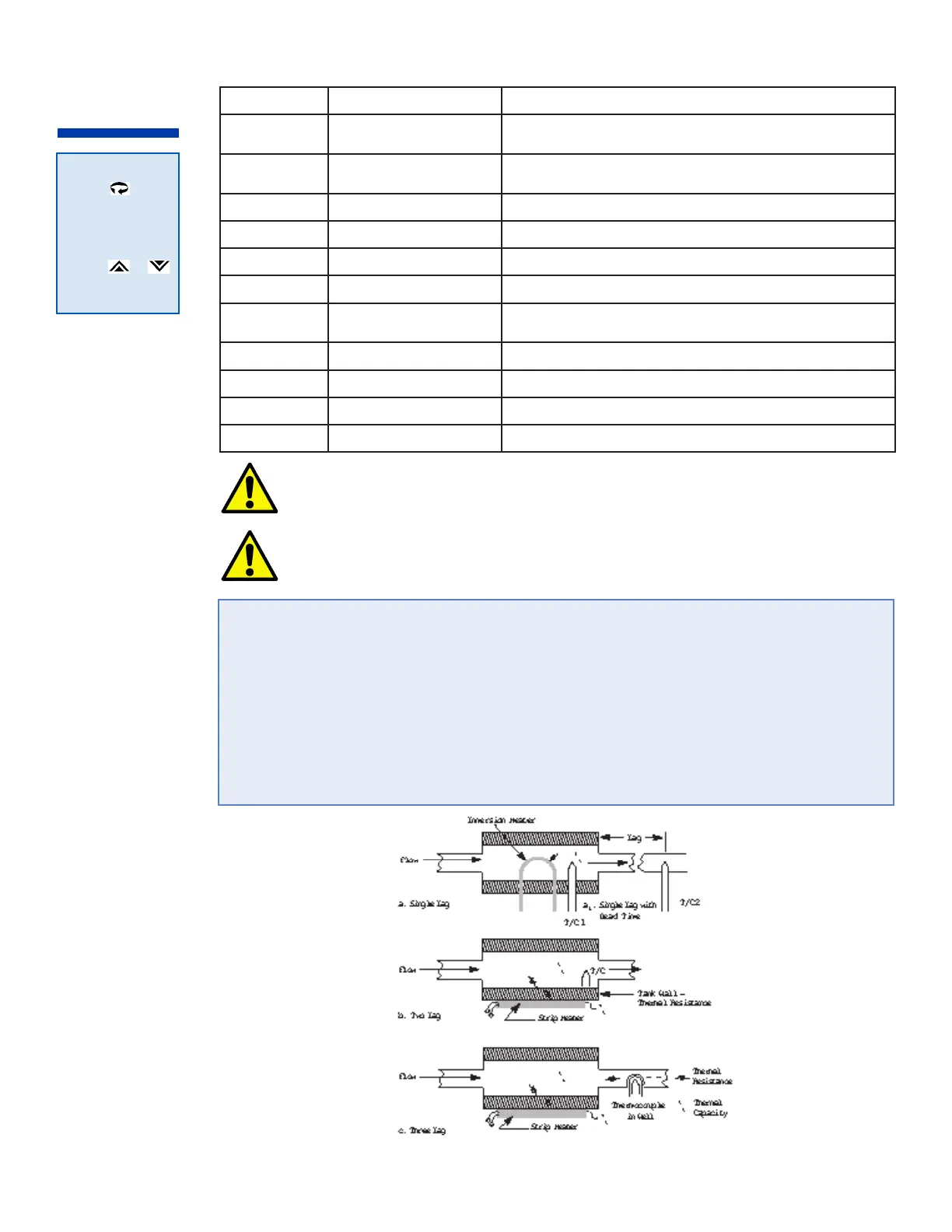

Figure 10. Typical Lag Processes

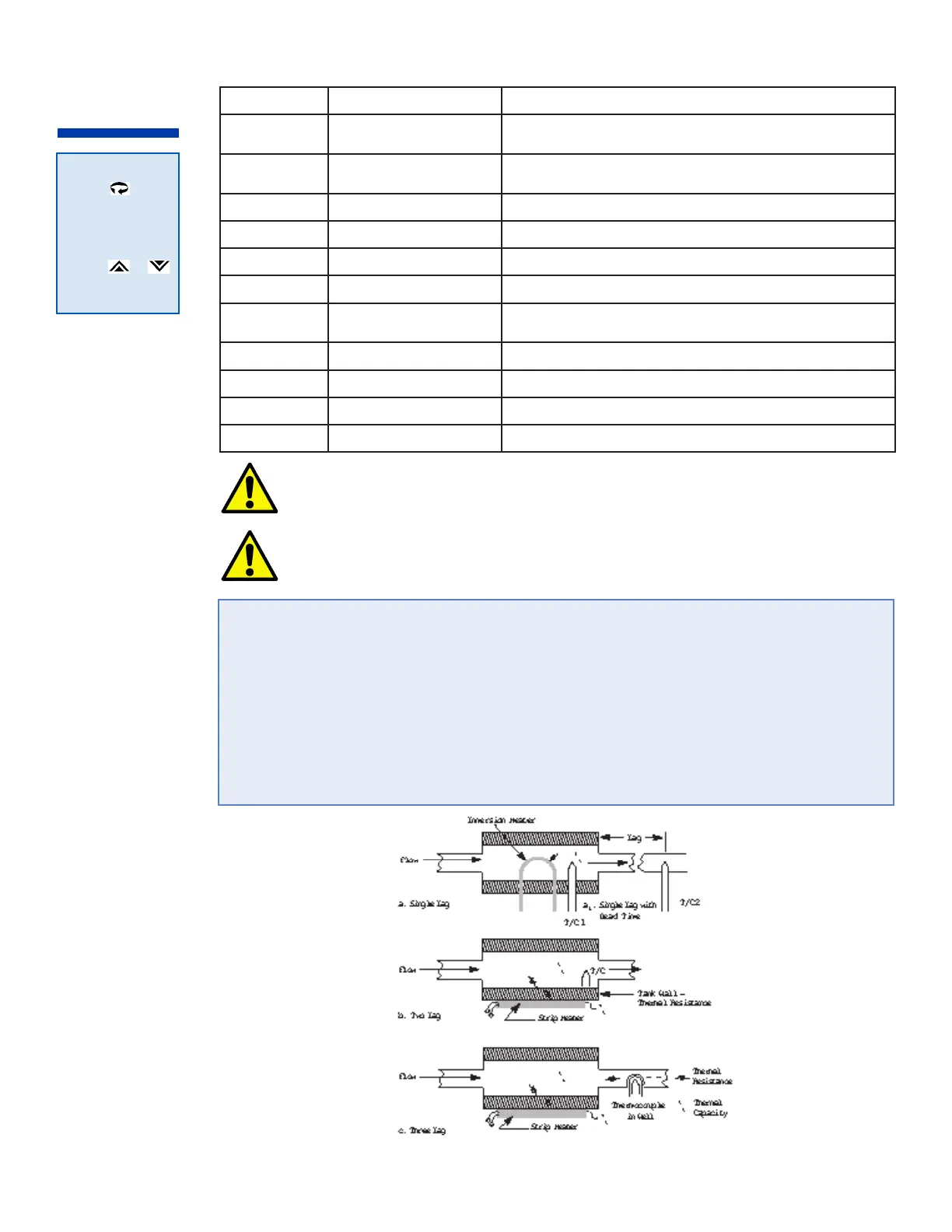

Parameter

Descriptions

Setting Rate (Derivative) or Reset (Integral) to [ 00 ] disables that aspect of PID control. The ratio

for non-zero settings of rate-to-reset is limited to a minimum of 1:4, i.e., Reset value cannot be set

any lower than four times Rate.

The parameters of Heat Hysteresis, Cool Hysteresis and Cool Spread are only available when

Output 1 and/or Output 2 are set to on/off mode [Ht.O] or [CL.O]. They replace Gain Output 1 and

Gain Ratio Output 2, respectively.

Notes on Damping: The damping parameter is an autotune feature that enables more precise control of

setpoint overshoot during recovery from process upsets in which thermal or transfer lag is a factor. See

Figure 12. Use the correct setting prior to autotuning to compensate for power and load/sensor coupling

characteristics.

Lo = Fast recovery with slight overshoot. For single-lag processes.

- Adequate power and excellent load/sensor coupling.

nL = Normal recovery with no overshoot. For two-lag processes.

- Properly sized heaters or components and good load/sensor coupling.

Hi = Slow recovery with no overshoot. For three-lag processes.

- Overpowered with multiple lags. Poor load/sensor coupling.

Off = Autotune disabled; manual output control.

Display Parameter Available Selections

Gn.o1

Gain Output 1 (PID heat

gain)

0 to 400 - value may exceed 400 during autotuning

Gr.o2

Gain Ratio Output 2 (PID

cool gain ratio)

0 to 20

H.HYS

Heat Hysteresis

01 to100 - degrees

C.HYS

Cool Hysteresis

0 to100 - degrees

HYS1

Output 1 Hysteresis

0 to100 units

HYS2

Output 2 Hysteresis

0 to100 units

SPr.2

Spread Adjustment,

Output 2

0 to100 units

C.SPr

Cool Spread

0 to100 - degrees

rAtE

PID rate

0 to 900 seconds

rSEt

PID reset

0 to 3600 seconds

dPnG

Damping

Lo , nL , Hi , Off

MENU "02"

How Do I Get Here?

Loading...

Loading...