EP5PTI19 HR10-MT EN Troubleshooting

© Atlas Copco Industrial Technique AB - 9839 0661 01

29

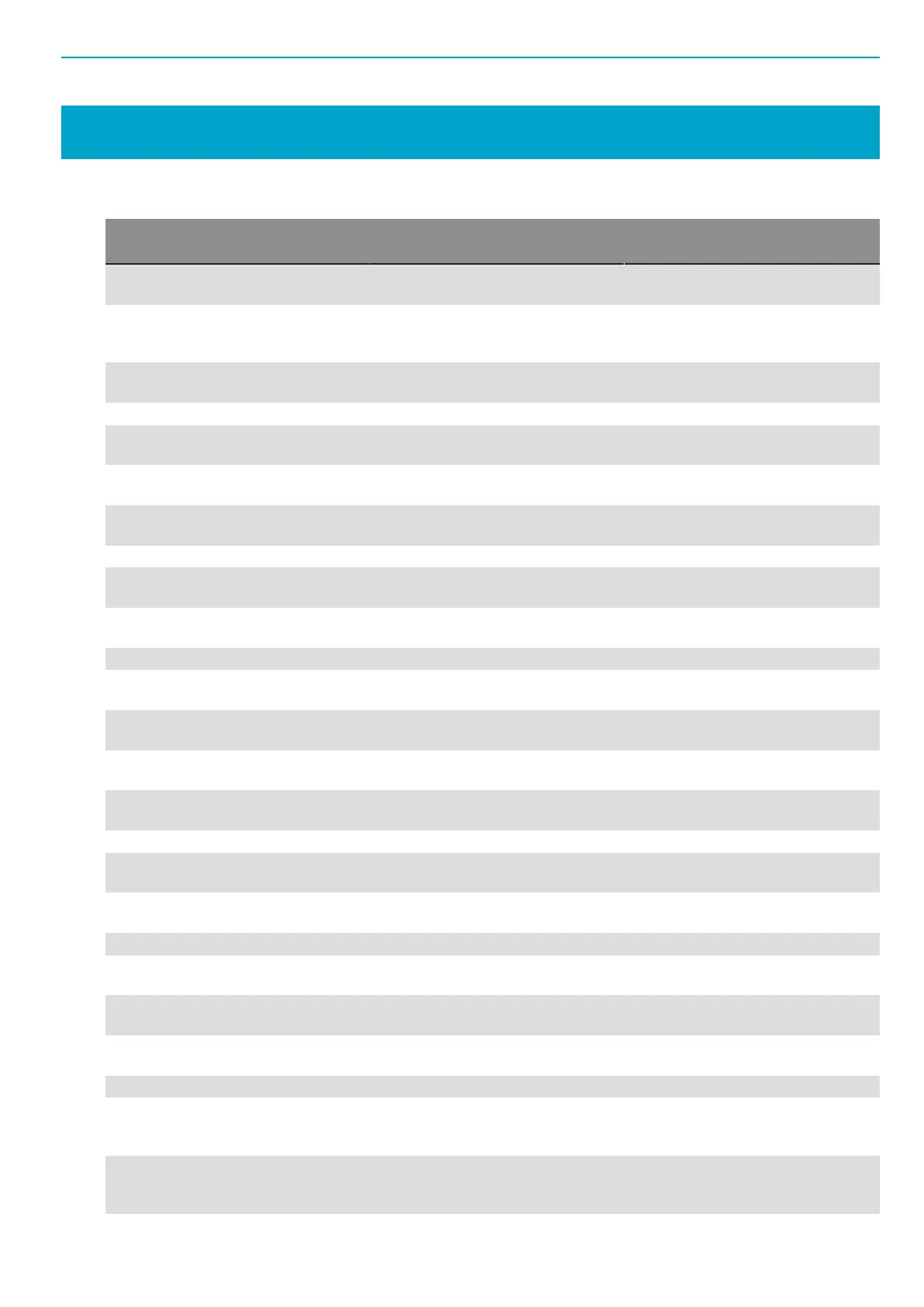

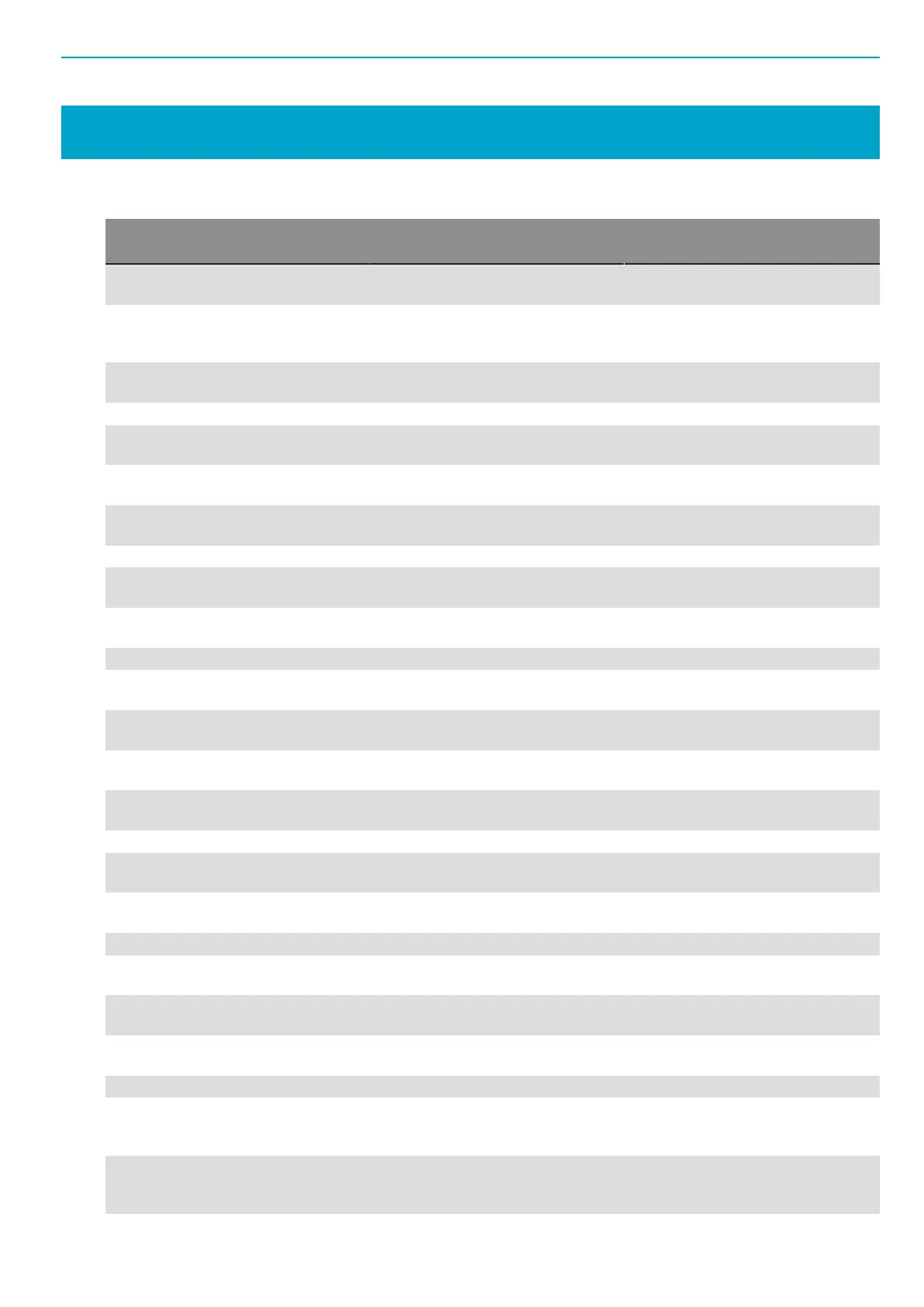

Troubleshooting

Trouble shooting guide

Problem Reason Action

The tool does not shut off, or the

tightening time is too long.

Target torque close to maximum

torque of the tool.

Chose a bigger tool with more

power.

Low dynamic air pressure. Check the dimensions of the hose

and couplings. Increase the air

pressure.

Low rotation speed. See Problem mode "The rotation

speed is too low".

The extension is too long. Check the extension.

Worn extension or socket/bits. Check the extension and socket/

bits.

Torque setting screw is turned too

much.

Adjust the torque setting screw

CCW until tool shuts off.

The Stop pin in the shut off mecha-

nism is incorrectly adjusted.

Check with a gauge.

Incorrect oil level in the Pulse unit. Adjust the oil level or refill the oil.

The joint is too soft for the tool. Chose a bigger tool with more

power.

Worn parts in the Pulse unit. Inspect and replace any worn

parts.

Malfunctioning AutoTrim. Check the AutoTrim function.

The yield point of the joint is

reached.

Check the joint specification.

The pulse frequency is too high or

too low.

Incorrect oil level in the Pulse unit. Adjust the oil level or refill the oil.

Inconsistent shut off or insufficient

accuracy

The target torque is not within the

tool specification.

Change to a different tool size.

Not enough pulses (hard joint and

low torque setting).

See Optimizing the performance of

your ErgoPulse tool.

Extension is too long. Check the extension.

Worn extension or socket/bits. Check the extension and socket/

bits.

Pressure fluctuations in the air sup-

ply.

Use a pressure regulator (for each

tool) to get a consistent air supply.

Incorrect oil level in the Pulse unit. Adjust the oil level or refill the oil.

Friction is too low on the Torque

setting screw.

Replace with new screw.

Worn parts in the Shut off mecha-

nism.

Inspect and replace any worn

parts.

Stop pin in the Shut off mechanism

is not correctly adjusted.

Check with a gauge.

Malfunctioning AutoTrim. Check the AutoTrim function.

The joint is too soft and max torque

setting.

Reduce the torque setting slightly,

or use a bigger tool with more

power.

The rotation speed is too low. Not enough air pressure. Check the dimensions of the hose

and couplings. Increase the air

pressure.

Loading...

Loading...