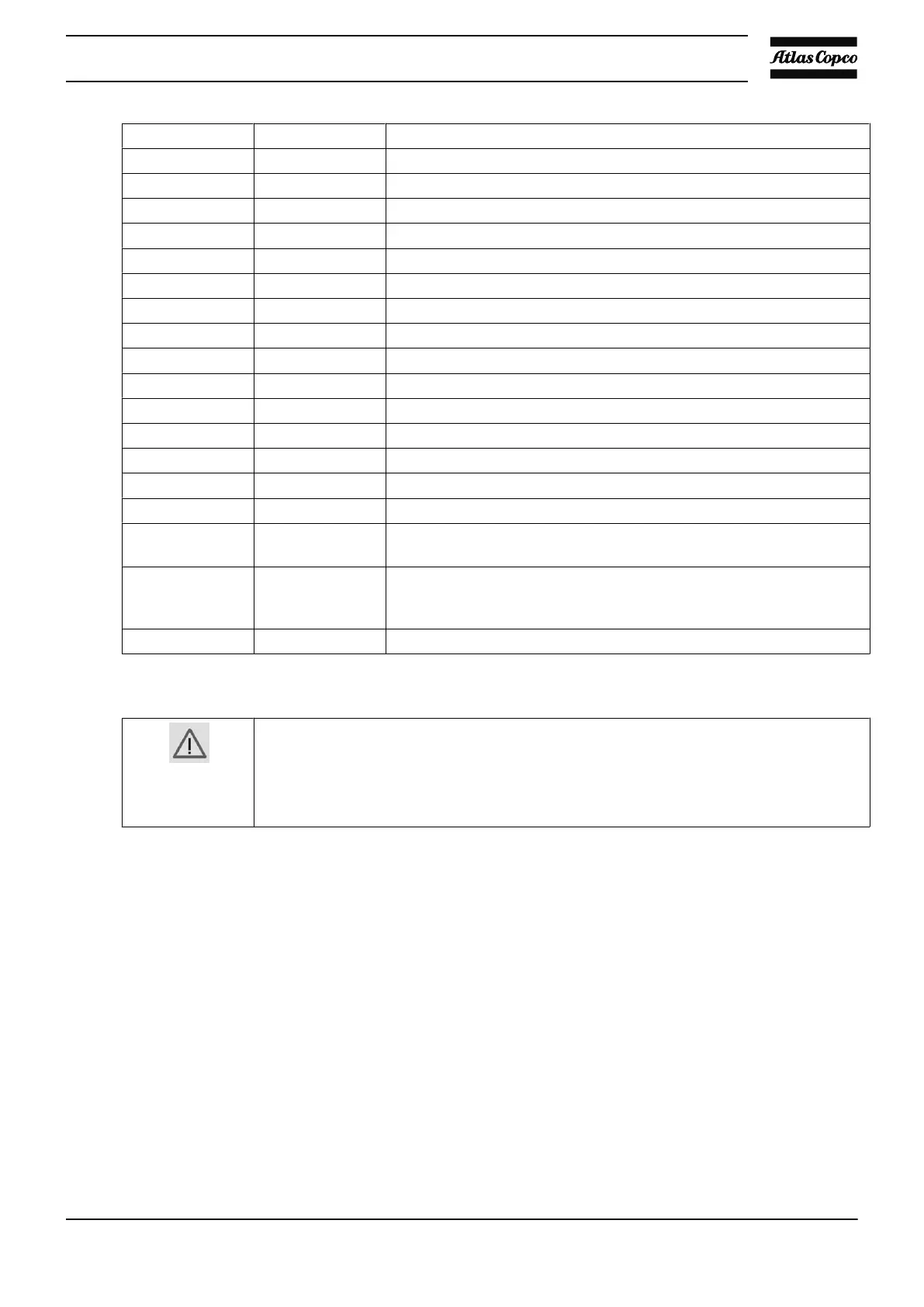

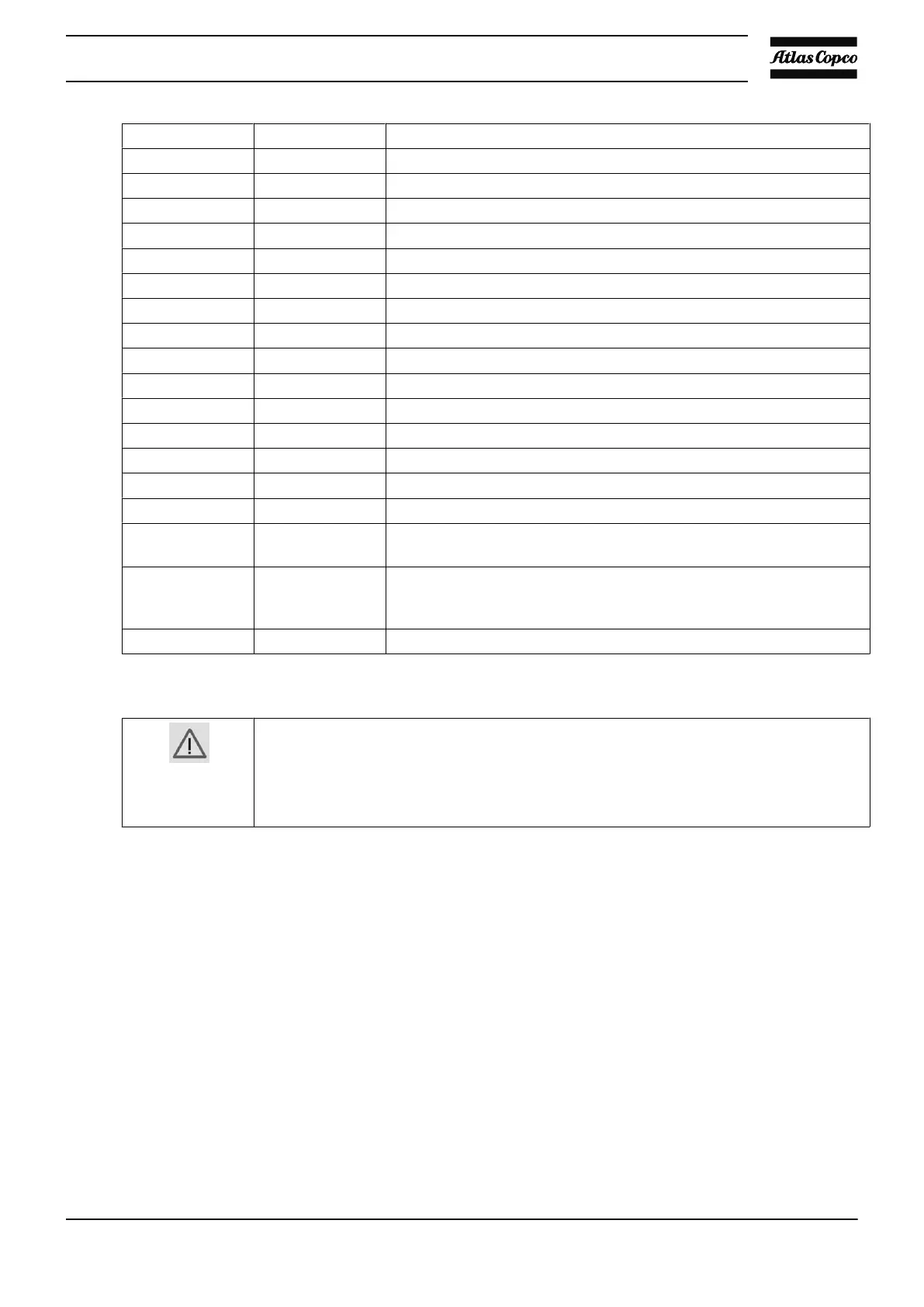

Running hours Service plan Operation

2000 -- If Atlas Copco Roto-Foodgrade Fluid is used, change oil and oil filter.

4000 A If Atlas Copco Roto-Inject Fluid is used, change oil and oil filter.

4000 B Replace air filter element.

4000 B Check condition of the air intake hose between air filter and element.

4000 B Check pressure and temperature readings.

4000 B Carry out a LED/display test.

4000 B Replace air filter pads of converter cabinet.

4000 B Check for possible leakage.

4000 B On air-cooled compressors: clean coolers.

4000 B On air-cooled compressors: check and clean cooling fan assembly.

4000 B Test temperature shut-down function.

4000 B Have safety valve tested.

4000 B Clean cooling fins of electric motors.

4000 B Inspect restrictor in scavenging line for cleanness.

4000 B Check operation of cooling fans of converter.

4000 B Check blow-off solenoid valve after stopping and pressing the

emergency stop button.

8000 C Have oil separator replaced.

Replace oil separator if the pressure drop exceeds 1 bar during loaded

running with a stable working pressure.

8000 C If Atlas Copco Roto-Xtend Duty Fluid is used, change oil and oil filter.

Important

•

Always consult Atlas Copco if a timer setting has to be changed.

•

For the change interval of oil and oil filter in extreme conditions of temperature,

humidity or cooling air, consult your Atlas Copco Customer Centre.

•

Any leakage should be attended to immediately. Damaged flexibles or flexible

joints must be replaced.

8.2 Drive motor

GA 75 VSD and GA 90 VSD

The bearing at the non-drive end side is greased for life.

The bearing at the drive end side is lubricated by the oil system.

Instruction book

2920 1634 04 91

Loading...

Loading...