3. Turn potentiometer [1] slightly in opposite direction.

4. Perform fine-tuning of the zero point at external setting potentiometer (for remote

indication).

9.13 Electronic position transmitter RWG: set

— Option —

The electronic position transmitter RWG records the valve position. On the basis of

the actual position value measured by the potentiometer (travel sensor), it generates

a current signal between 0 – 20 mA or 4 – 20 mA.

Table 8: Technical data RWG 4020

3- or 4-wire systemWiring

TP_ _4/ _ _ _KMSTerminal plan

0 – 20 mA, 4 – 20 mAI

A

Output current

24 V DC, ±15 % smoothedU

V

Power supply

24 mA at 20 mA output currentIMax. current consump-

tion

600 ˖

R

B

Max. load

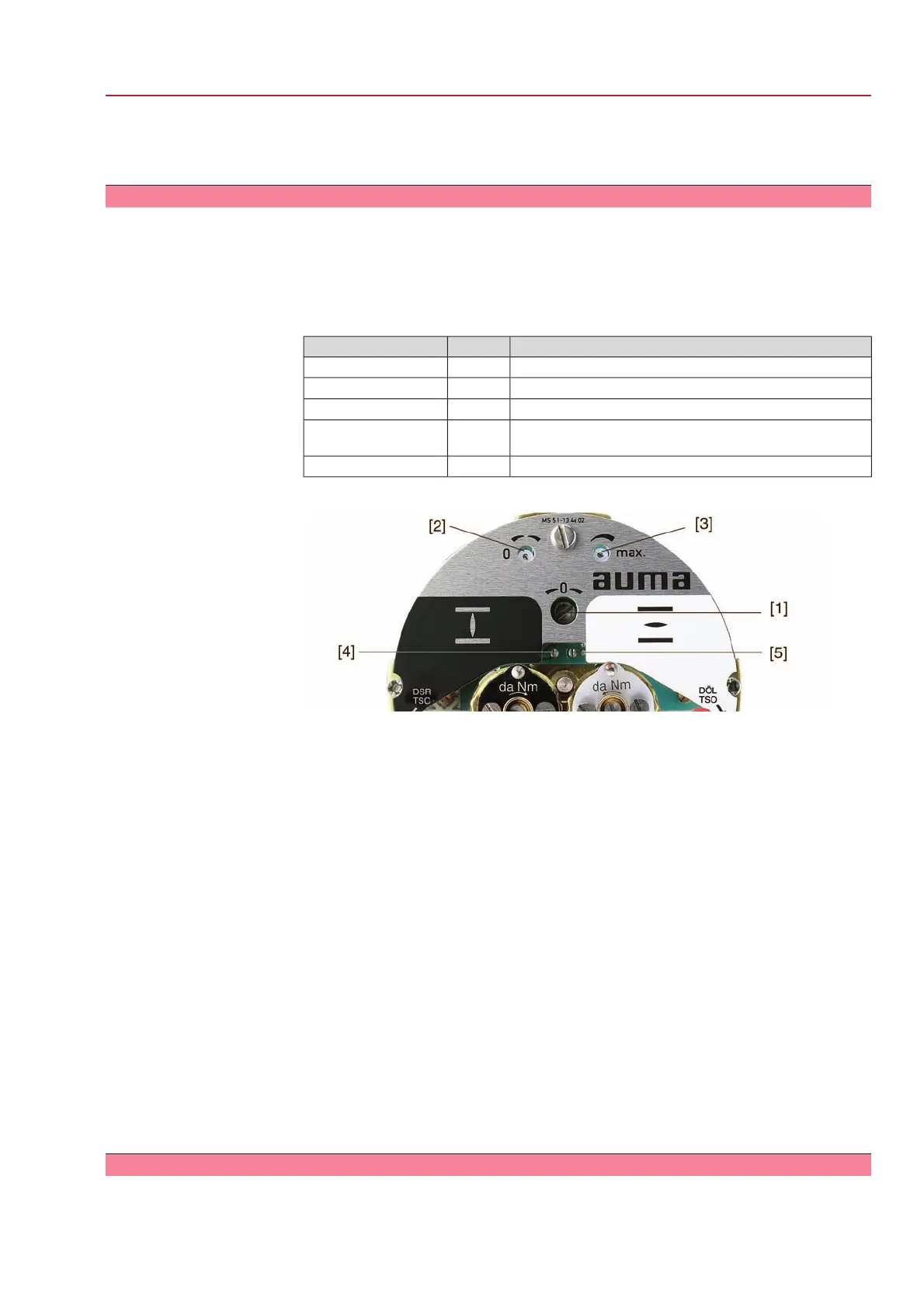

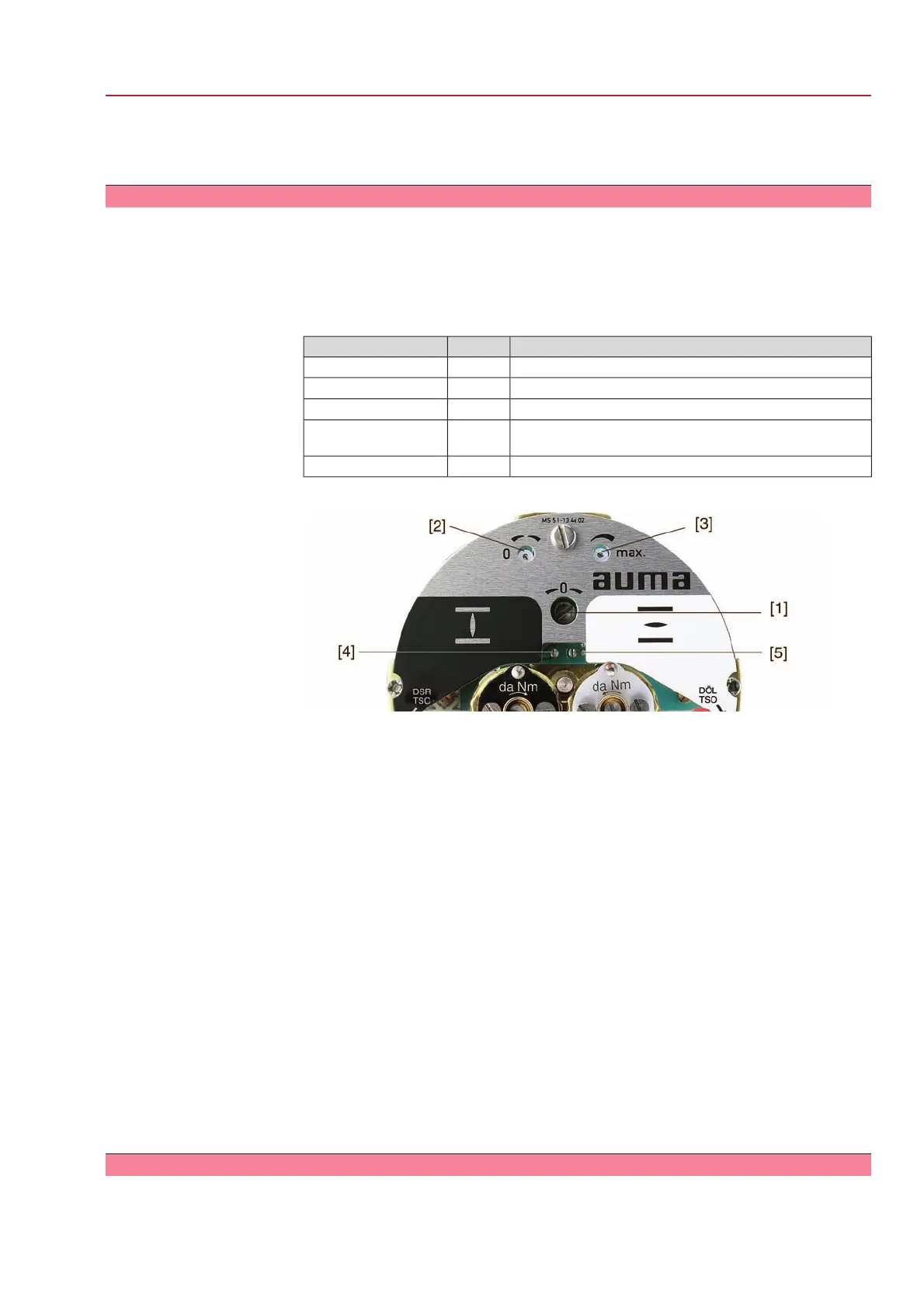

Figure 52: View of control unit

[1] Potentiometer (travel sensor)

[2] Potentiometer min. (0/4 mA)

[3] Potentiometer max. (20 mA)

[4] Measuring point (+) 0/4 – 20 mA

[5] Measuring point (–) 0/4 – 20 mA

1. Connect voltage to electronic position transmitter.

2. Move valve to end position CLOSED.

3. Connect ammeter for 0 – 20 mA to measuring points [4 and 5].

4. Turn potentiometer [1] counterclockwise to the stop.

5. Turn potentiometer [1] slightly in opposite direction.

6. Turn potentiometer [2] clockwise until output current starts to increase.

7. Turn potentiometer [2] in opposite direction until the following value is reached:

- for 0 – 20 mA approx. 0.1 mA

- for 4 – 20 mA approx. 4.1 mA

➥

This ensures that the signal remains above the dead and live zero point.

8. Move valve to end position OPEN.

9. Set potentiometer [3] to end value 20 mA.

10. Approach end position CLOSED again and check minimum value (0.1 mA or

4.1 mA). If necessary, correct the setting.

9.14 Mechanical position indicator: set

1. Place indicator disc on shaft.

53

SG 05.1 – SG 12.1/SGR 05.1 – SGR 12.1 Control unit: electromechanic

AC 01.1 Intrusive Modbus RTU Commissioning (basic settings)

Loading...

Loading...