●

Actuators with electromechanical control unit or actuator with electronic control

unit and limit switches.

●

One of the following safety functions:

- Safe ESD function “Safe CLOSING” (Safe ESD in direction CLOSE)

- Safe ESD function “Safe OPENING” (Safe ESD in direction OPEN)

●

Configuration of “SIL seating”

= “no seating”

Also valid for combination of Safe ESD with Safe STOP.

Information

For version of electronic control unit with limit switches, steps 6 – 9 are obsolete.

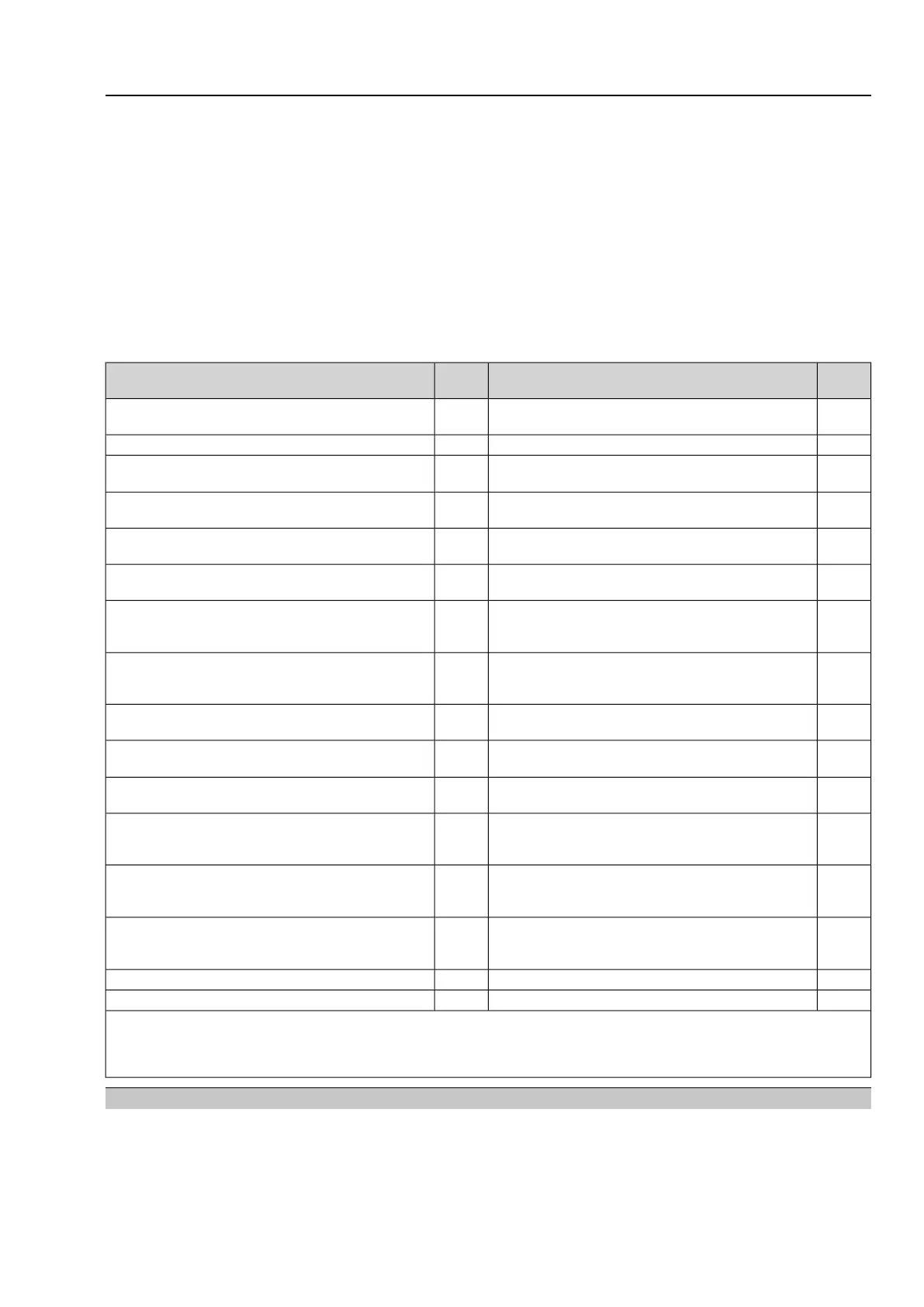

Table 29: Checklist 9

✎Configuration

Safe OPENING (Safe ESD in direction OPEN)

✎Configuration

Safe CLOSING (Safe ESD in direction CLOSE)

⎕ ✓1. Is actuator in mid-position or at sufficient distance

from the end positions?

⎕ ✓1. Is actuator in mid-position or at sufficient distance

from the end positions?

⎕ ✓2. Switch compartment opened?⎕ ✓2. Switch compartment opened?

⎕ ✓

3. Safe ESDa and Safe ESDb input signals

set to 0 V (low)?

⎕ ✓

3. Safe ESDa and Safe ESDb input signals

set to 0 V (low)?

⎕ Yes

⎕ No

➥ Check actuator reaction:

Safety operation initiated?

⎕ Yes

⎕ No

➥ Check actuator reaction:

Safety operation initiated?

⎕ ✓4. Limit switch OPEN operated?

(Test button [2] turned in direction of the LSO arrow?)

⎕ ✓4. Limit switch CLOSE operated?

(Test button [1] turned in direction of the LSC arrow?)

⎕ Yes

⎕ No

➥ Check actuator reaction:

Safety operation not stopped?

⎕ Yes

⎕ No

➥ Check actuator reaction:

Safety operation not stopped?

⎕ ✓

5.1 Safe ESDa and Safe ESDb input signals

set to +24 V DC (high) prior to reaching the end pos-

ition?

⎕ ✓

5.1 Safe ESDa and Safe ESDb input signals

set to +24 V DC (high) prior to reaching the end pos-

ition?

⎕ ✓5.2 Actuator operated via local controls or from RE-

MOTE to end position OPEN and then to end position

CLOSED?

⎕ ✓5.2 Actuator operated via local controls or from RE-

MOTE to end position OPEN and then to end position

CLOSED?

⎕ ✓5.3 Actuator operated to mid-position or at sufficient

distance from the end positions?

⎕ ✓5.3 Actuator operated to mid-position or at sufficient

distance from the end positions?

⎕ ✓

6. Safe ESDa and Safe ESDb input signals

set to 0 V (low)?

⎕ ✓

6. Safe ESDa and Safe ESDb input signals

set to 0 V (low)?

⎕ ✓7.Torque switch OPEN operated?

(Test button [2] turned in direction of the TSO arrow?)

⎕ ✓7.Torque switch CLOSE operated?

(Test button [1] turned in direction of the TSC arrow?)

⎕ Yes

⎕ No

➥ Check actuator reaction:

Safety operation not stopped?

Display illuminated in red?

⎕ Yes

⎕ No

➥ Check actuator reaction:

Safety operation not stopped?

Display illuminated in red?

⎕ Yes

⎕ No

➥ Check SIL module signal behaviour:

SIL fault signal?

SIL failure output (NC contact) = closed)

⎕ Yes

⎕ No

➥ Check SIL module signal behaviour:

SIL fault signal?

SIL failure output (NC contact) = closed)

⎕ ✓

8. Safe ESDa and Safe ESDb input signals

set to +24 V DC (high) prior to reaching the end pos-

ition?

⎕ ✓

8. Safe ESDa and Safe ESDb input signals

set to +24 V DC (high) prior to reaching the end pos-

ition?

⎕ ✓9.Torque fault of standard controls acknowledged?⎕ ✓9.Torque fault of standard controls acknowledged?

⎕ ✓10. Switch compartment closed?⎕ ✓10. Switch compartment closed?

☒ ✓ = Executed

☒ Yes = Condition met

☒ No = Condition not met

If the answer to one of the questions is no, the safety instrumented system must be checked.

11.2.9. Safe STOP function – irrespective of the selected control unit

Proof test checklist for version or configuration:

“SIL function” = “Safe STOP OPEN/CLOSE” (safe stop) configuration.

Also valid for combination of Safe ESD with Safe STOP.

51

Part-turn actuators

with AC 01.2-SIL/ACExC 01.2-SIL Checklists

Loading...

Loading...