57

600 Series

Maintenance and service

If counterweights are added or removed

16. Calibration of the load sensor

Risk of tipping over - The load

sensor may not give correct

information if it is not calibrated

after adding or removing

counterweights. The load sensor

must be calibrated if you add or

remove two or more AVANT rear

weights (+/- 58 kg).

Risk of tipping of the loader

and crushing under lowering

load - Do the calibration on at,

solid ground, and do not go near

the boom of the loader. During

the calibration procedure of the

load sensor it is necessary to lift a

heavy load, deliberately causing

the loader to tip forward.

• Use the loader boom only just

enough to lift the rear wheels of

the ground.

• Keep your hands and feet away

from the rear wheels while doing

the calibration.

• Do not allow anyone to stay at

the driver’s seat of the loader

while adjusting the load sensor

-Accidental movements of the

loader can injure!

• Remove the cover panels from

the rear of the loader before you

start the calibration procedure.

• Lift only solid objects when doing

the calibration. If you lift soft

materials e.g. sand with bucket,

the loader can move if sand

starts to drain from the bucket.

• Keep away from the hot parts

of the engine while doing the

calibration.

To calibrate the load sensor:

1. Add or remove the counterweights from the loader.

2. Remove the engine cover plate and the lower left side

rear cover plate.

3. Lift something so heavy with the loader that the rear

wheels lift off the ground.

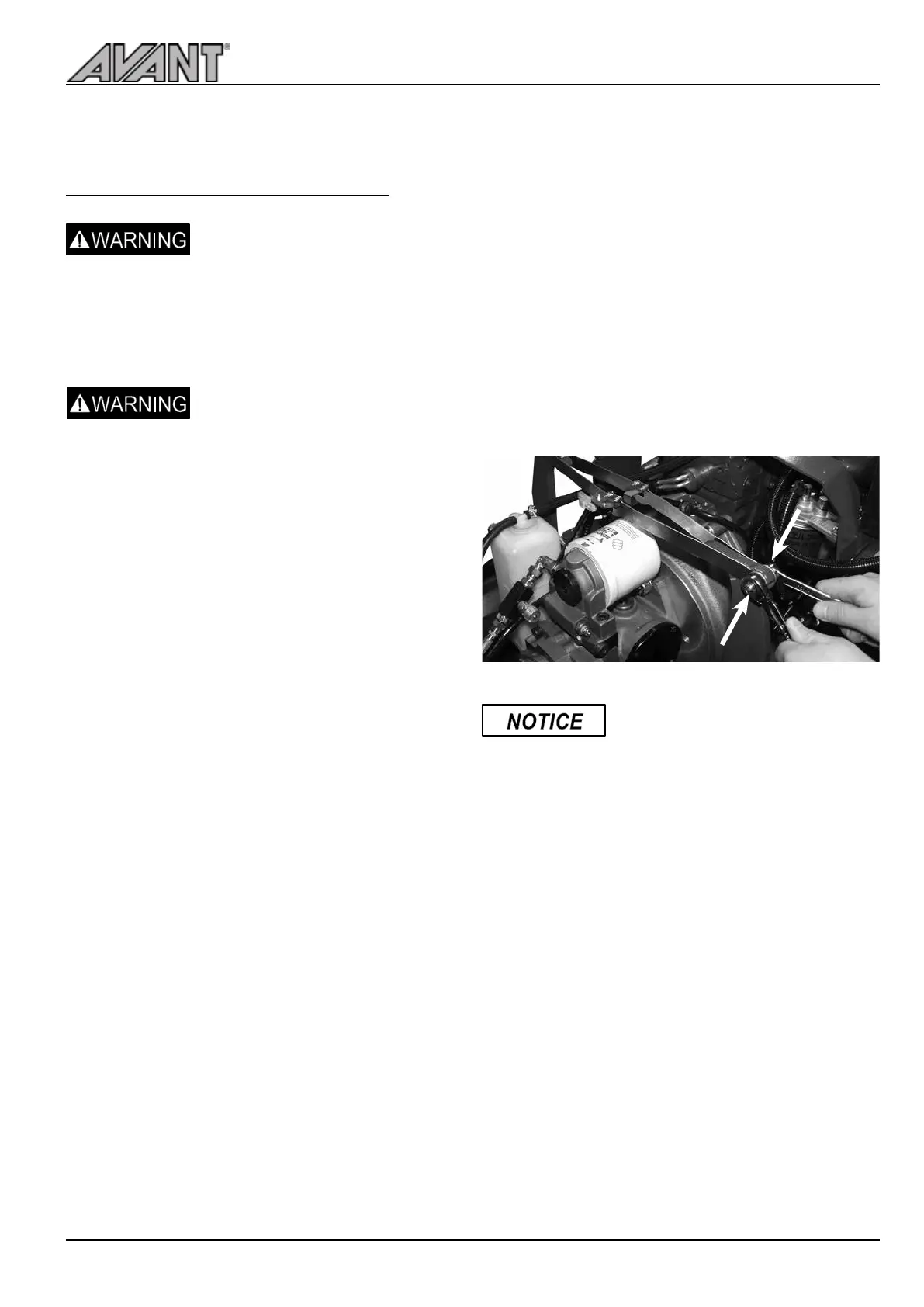

4. Open the screw pointed by the arrows (see picture

below) with two 13 mm keys. As the two steel strips

come in contact and trigger the switch, tighten the

screw.

5. Lower the rear wheels back to the ground and mount

the cover plates.

6. Check function of the load sensor.

The rear wheels must be lifted by

using the loader boom in order

that the adjustment can be done

correctly. The rear of the loader

can not be lifted with a jack in order

to do the calibration correctly.

Loading...

Loading...