11-7

(3/3)

Step Procedure

7

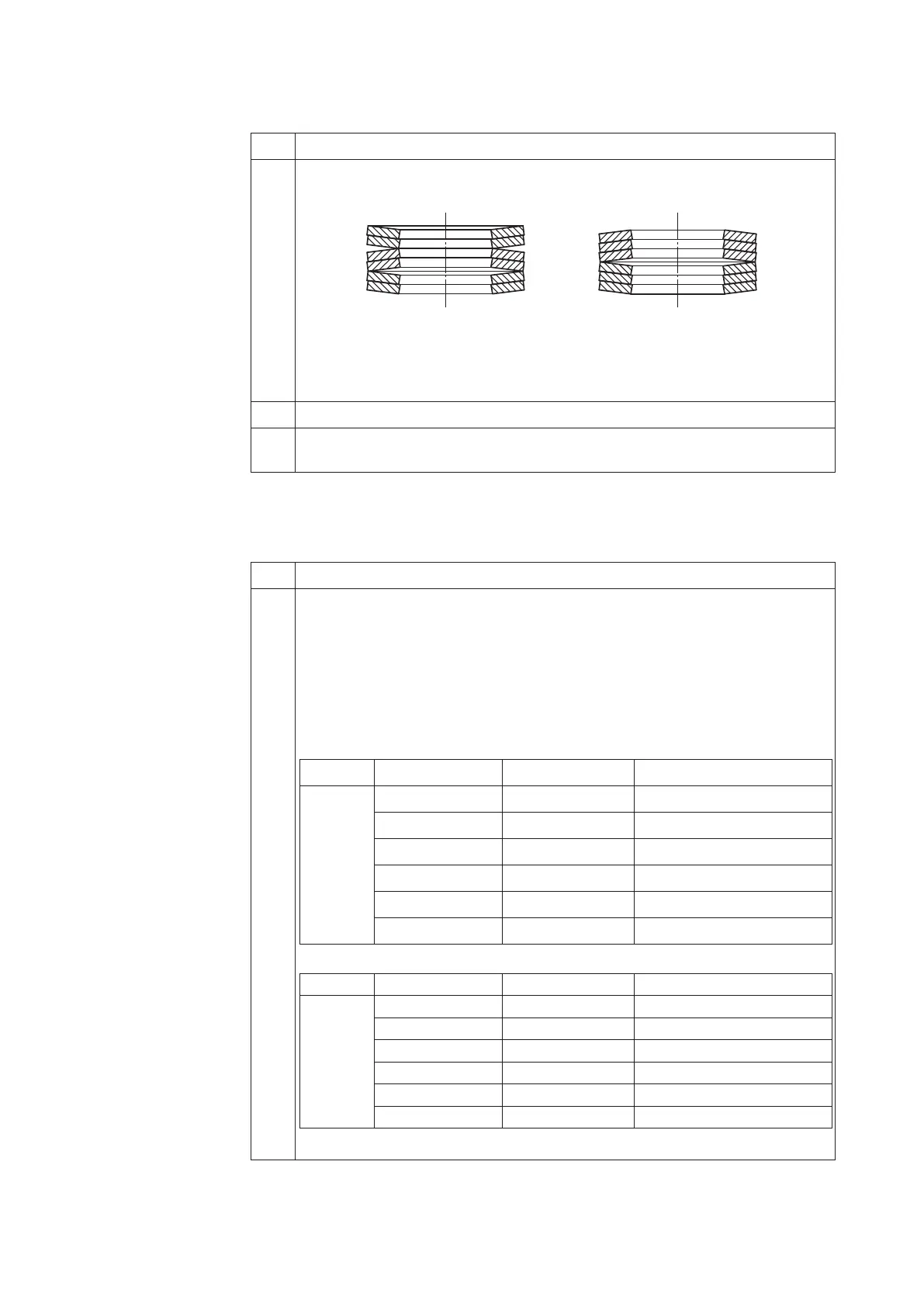

Stack the Belleville spring washers as shown in Fig. 11-5, and insert them into the

packing follower.

2 same-direction washers × 3 3 same-direction washers × 2

[For PTFE yarn] [For expanded graphite]

Fig. 11-5.

8 Place the packing flange onto the packing follower.

9

Apply anti-seizing agent Never-Seez made by Bostik Inc. (Table 11-3) to the threads

on the gland nut end of the gland studs, and screw the nuts on by hand.

(3) Tightening

(1/2)

Step Procedure

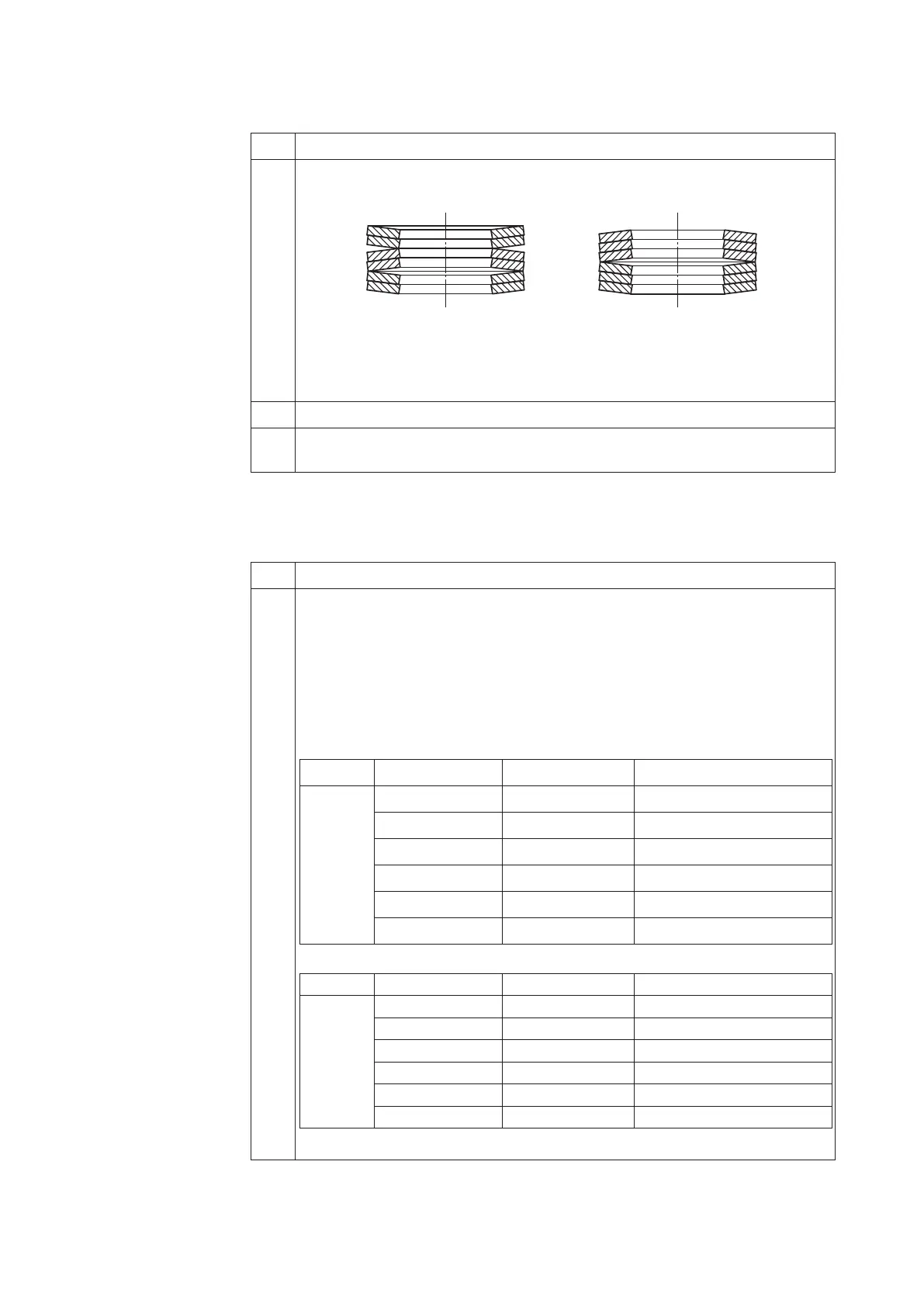

1

Tighten the left and right gland nuts alternately, making approximately a half turn

each, until the torque indicated in Table 11-4 or Table 11-5 is reached. Note that if

the tightening torque is insufficient, the amount of leakage may exceed the specified

value. On the other hand, tightening the gland nuts with excessive torque increases

the friction on the stem and causes the gland packing to wear out faster, which may

lead to an amount of leakage exceeding the specified value in a short period of time.

Table 11-4. Gland nut tightening torque (for PTFE yarn)

Model Actuator model Stem size Tightening torque

HLS,HLC

HTS,HSC

HA2

φ

10 mm 12 N·m

HA3

φ

13 mm 20 N·m

HA3

φ

16 mm 33 N·m

HA4

φ

20 mm 44 N·m

PSA6,DAP560

φ

30 mm 54 N·m

DAP1000(X)

φ

40 mm 65 N·m

Table 11-5. Gland nut tightening torque (for expanded graphite)

Model Actuator model Stem size Tightening torque

HLS,HLC

HTS,HSC

HA2

φ

10 mm 12 → 0 (loosening) → 8 N·m

HA3

φ

13 mm 20 → 0 (loosening) → 13 N·m

HA3

φ

16 mm 33 → 0 (loosening) → 22 N·m

HA4

φ

20 mm 44 → 0 (loosening) → 30 N·m

PSA6,DAP560

φ

30 mm 54 → 0 (loosening) → 36 N·m

DAP1000(X)

φ

40 mm 85 → 0 (loosening) → 43 N·m

Loading...

Loading...