10-3

3. Preparation of lubricating grease and anti-seize compound

Prepare proper amounts of lubricating grease and anti-seize compound indicated in the

following table. (Equivalents also can be used.)

Table 10-3. Lubricating grease and anti-seize compound

Product name Area to be coated

Silicone grease G40M made by Shin-Etsu

Chemical Co., Ltd.

Entire surface of the gland packing

Plastilube No. 3 made by Sulflo, Inc., in the

U.S.

Entire surface of the backup O-rings

Anti-seize compound Never-Seez made by

Bostik, Inc., in the U.S.

Surface of the threads of the gland studs

Bearing surface of the gland nuts

10-3-2. Start of installation

1. Coating with lubricating grease

Step 1: Apply a thin film (not more than 0.3 mm thick) of the grease indicated in Table 10-3

[G40M made by Shin-Etsu Chemical Co., Ltd.] to the entire surface of all the gland packing.

Step 2: Apply the grease indicated in Table 10-3 [Plastilube No. 3 made by Sulflo, Inc., in the

U.S.] to each of the two backup O-rings on the inner diameter side and the outer diameter side

of the packing follower.

2. Installation of parts

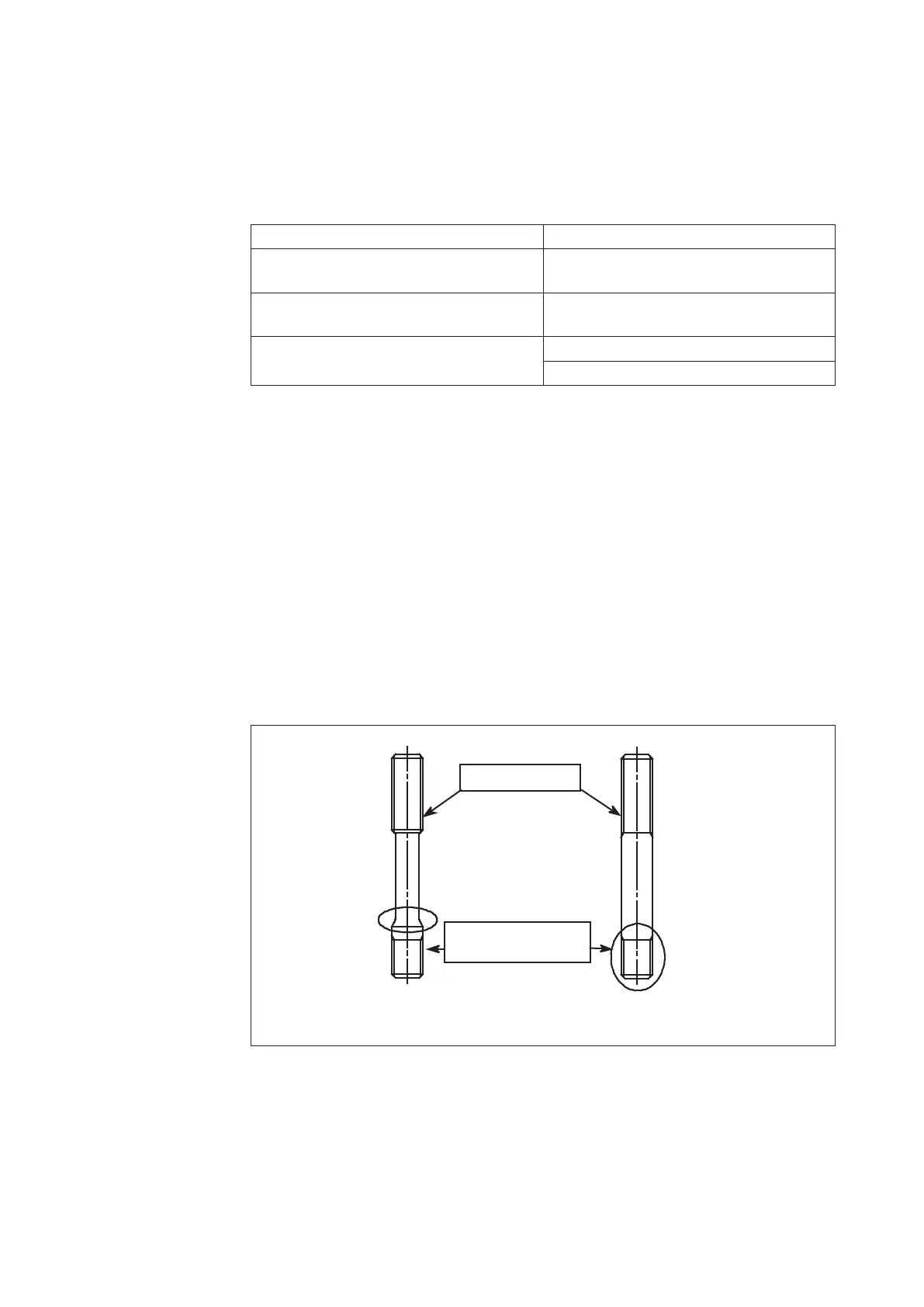

Step 1:

With reference to Fig. 10-2, check the direction of the gland studs. After applying the anti-

seize compound indicated in Table 10-3 [Never-Seez made by Bostik, Inc., in the U.S.] to the

surface of the threads, install them into the stuffing box.

Gland nut side

Taper side

Stung box side

Shorter threaded part side

Fig. 10-2. Direction of the gland studs

Loading...

Loading...