2-2

2-1. Item to be checked after installation and before starting operation

(1) Check that there is no leak from air piping.

(2) Check that the bolts and nuts of the diaphragm case are not loose. Standard tight.ening

torques are as follows:

(3) Tighten the packing flange nuts to prevent leak from the gland packing chapter. Standard

tightening torques are as shown in Table 2-2.

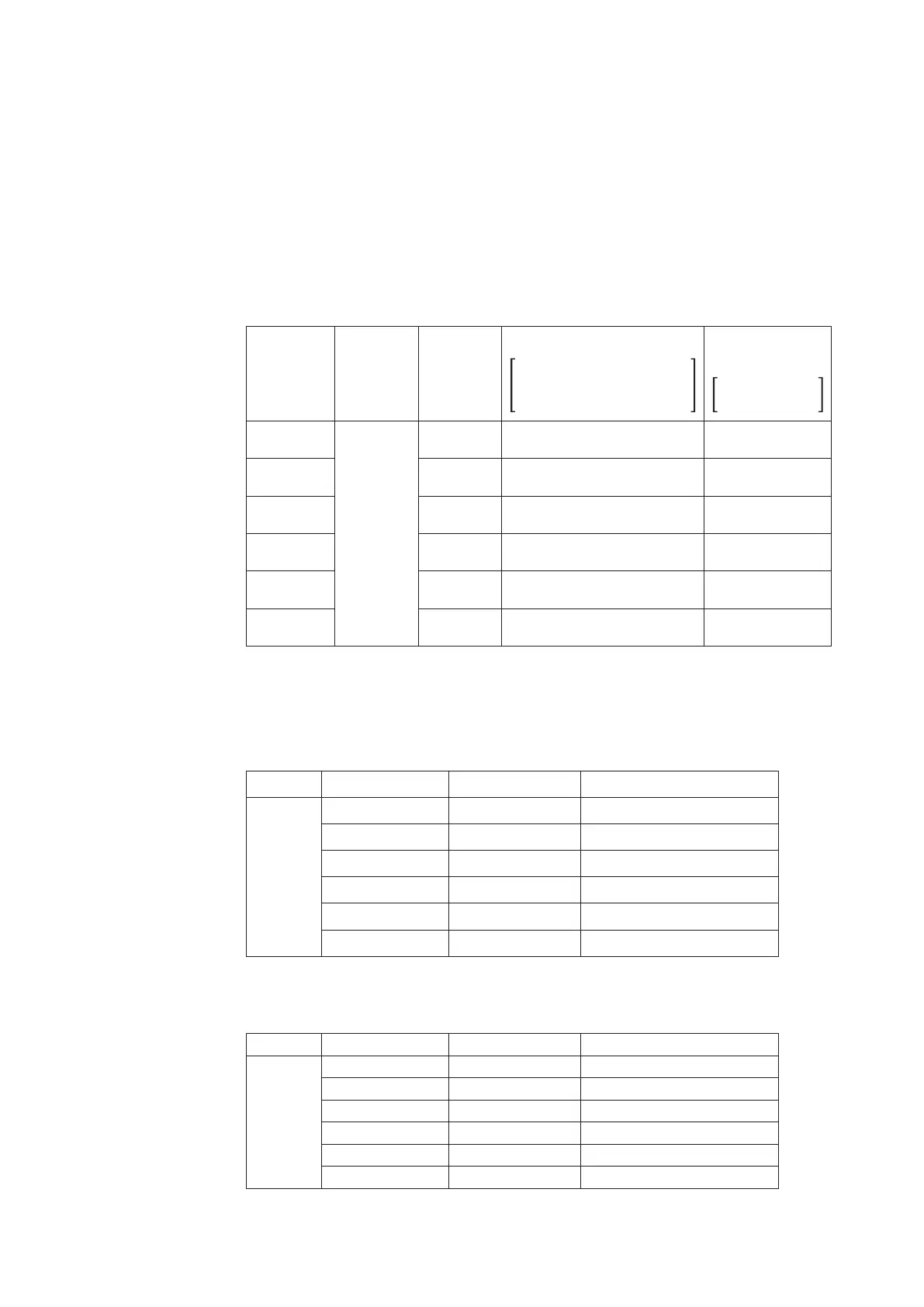

Table 2-2. Tightening Torques of Packing Flange Nuts

Unit: N•m{kgf/cm

2

}

Valve Stem

Diameter

(mm)

V PTFE

packing

PTFE Yarn

Packing

(P4519)

Expanded graphite Packing V PTFE + PTFE

P6610CH + P6528

P6610CH + M8590

T2200 + P6710CH (Type2)

Yarn Packing

PTFE + V7233

PTFE + TK2006

10

1 {8}

9 {90} 5 {50} 3 {30}

13 15 {150} 8 {80} 5 {50}

16 24 {240} 13 {130} 8 {80}

20 32 {320} 18 {180} 10 {100}

25 - - 28 {280} 15 {150}

30 66 {660} 36 {360} 20 {200}

Note: The tightening torques mentioned in the above are only to give you reference values.

Note that tightening torques may vary depending on the type of packing.

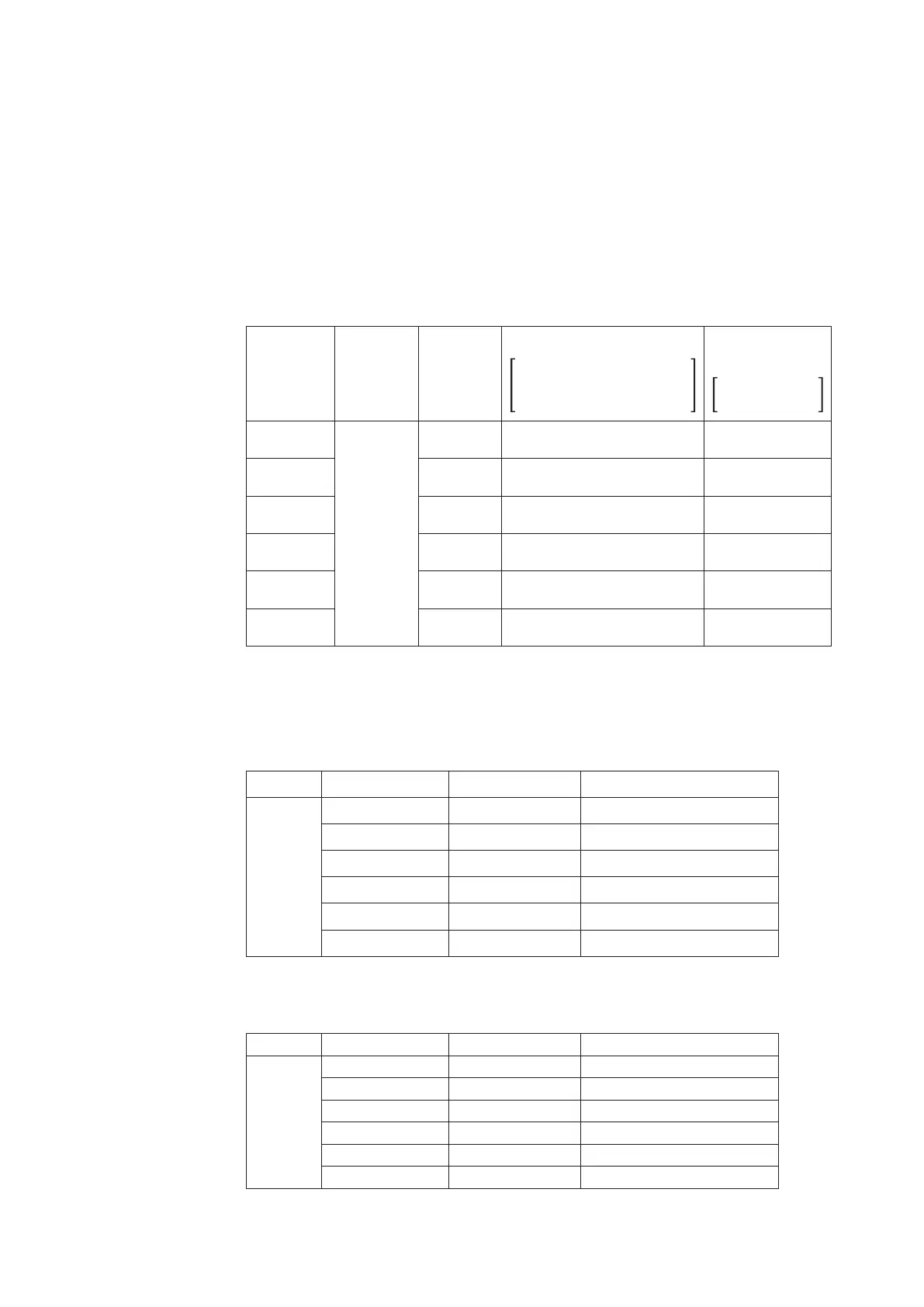

Table 2-3. Tightening Torques of packing Flange Nuts for PTFE yarn (Certified ISO

15848-1-compliant low-emission gland packing)

Model Actuator model Stem size Tightening torque

HLS,HLC

HTS,HSC

HA2

φ

10 mm 12 N·m

HA3

φ

13 mm 20 N·m

HA3

φ

16 mm 33 N·m

HA4

φ

20 mm 44 N·m

PSA6,DAP560

φ

30 mm 54 N·m

DAP1000(X)

φ

40 mm 65 N·m

Table 2-4. Tightening Torques of packing Flange Nuts for expanded graphite (Certified ISO

15848-1-compliant low-emission gland packing)

Model Actuator model Stem size Tightening torque

HLS,HLC

HTS,HSC

HA2

φ

10 mm 12 → 0 (loosening) → 8 N·m

HA3

φ

13 mm 20 → 0 (loosening) → 13 N·m

HA3

φ

16 mm 33 → 0 (loosening) → 22 N·m

HA4

φ

20 mm 44 → 0 (loosening) → 30 N·m

PSA6,DAP560

φ

30 mm 54 → 0 (loosening) → 36 N·m

DAP1000(X)

φ

40 mm 85 → 0 (loosening) → 43 N·m

Loading...

Loading...