Meter Installation

Follow these steps to install the E-Series Ultrasonic Plus meter:

1. Begin at this step if cutting in for new service. If cutting in is not required, begin at step 2.

• Close the curb (shutoff) valve to relieve water pressure in the line before starting the cutting operation. Be sure

to use a high-quality upstream shutoff valve with a low pressure drop.

• Flush the pipe to clear chips, pipe dope or other plumbing residue.

2. Close the meter inlet-side valve.

3. Open a faucet and wait until water ow stops to depressurize the system. Do not remove the existing meter until the

water ow stops.

DEPRESSURIZE THE LINE BEFORE STARTING ANY DISASSEMBLY OPERATION. REMOVING A METER THAT IS UNDER

LINE PRESSURE CAN RESULT IN COMPONENTS BECOMING PROJECTILES, CAPABLE OF CAUSING PERSONAL INJURY.

4. Check the service valves and make necessary repairs to the curb (shuto) valve or inlet side valve, if necessary.

5. Before installing or removing a meter, close the outlet-side valve to relieve pressure. Protect the area around the

meter against potential spills or leaks that could occur.

6. To replace an existing meter continue with step 7. To install a new meter skip to step 9.

7. Loosen the meter couplings or ange bolts and remove the existing meter and the old gaskets in the coupling nuts.

We recommend replacing the old gaskets with the provided thick rubber gaskets (PN: 34819-038).

8. Clean the coupling nuts or ange bolts, removing any pipe dope, old gasket material, or dirt from the threads or

ange bolts.

9. Check the existing position for proper alignment and spacing. Correct any misalignment or spacing issues.

10. Place the connection gaskets inside the connection coupling nuts.

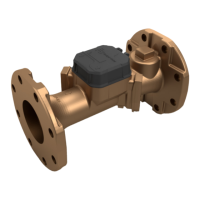

11. Install the meter in the pipeline in a horizontal or vertical position with the flow arrow on the meter pointing in the

direction of flow. Registration should be upright.

Start the coupling nuts at the threaded meter ends. Verify that the nuts are properly aligned to avoid damage to the

meter ends. An eective method for starting a coupling nut is:

• Position the nut squarely against the meter spud end.

• Turn the nut counterclockwise (left) while holding the nut against the meter spud end. When the first

threads on both the nut and the spud end coincide, you will hear a slight click and feel the nut move into the

starting position.

• Turn the nut clockwise (right) until it is hand-tight.

• With an open-end wrench, apply a partial turn. Do not over tighten.

12. After the meter is installed, slowly open the inlet shuto valve until the meter is full of water and make sure there are

no leaks. (The more ow you allow through the meter, appropriate for the meter size, the better.)

13. Slowly open the outlet valve until air is out of the meter and service line.

14. Open a service valve downstream of the meter and verify that no foreign debris in the water obstructs the operation

of the system.

15. Check the read on the meter to make sure it is registering a positive number. If it is not, make sure the meter is

installed with the ow arrow on the meter pointing in the direction of ow.

• The meter is shipped in Storage mode so that customers do not experience alarms during shipment or

installation. In general, a meter may take up to 2 minutes to begin measurement once the meter senses a

full pipe.

• The meter requires that the pipe is cleared of air and filled with water. If the customer is attempting to purge the

meter at low flow rates, it would likely be more difficult and take longer.

16. When the meter starts recording positive ow, note the meter reading for your records.

Meter Installation

Page 6 August 2020ESM-UM-02156-EN-02

Loading...

Loading...