BTL5-A/C/E/G1_-M/U_ _ _ _-K-SR 32/K_ _

Micropulse Linear Transducer - Rod Style

3

english

2.1 Characteristics

Micropulse transducers feature:

– Very high resolution, repeatability

and linearity

– Wear- and maintenance-free

– Immunity to shock, vibration, con-

tamination and electrical noise

– An absolute output signal

– Pressure rated to 600 bar

– Protection class per IEC 529:

IP 67 for connector version,

IP 68 (5 bar/48 h) for cable version

2.2 Function

The Micropulse transducer contains

a tubular waveguide enclosed by an

outer stainless steel rod. A magnet

attached to the moving member of

the machine or to the cylinder pis-

ton is moved over the rod and its

position constantly updated.

The magnet defines the measured

position on the waveguide. An inter-

nally generated INIT pulse interacts

with the magnetic field of the mag-

net to generate a magnetostrictive

torsional wave in the waveguide

which propagates at ultrasonic

speed.

The torsional wave arriving at the

end of the waveguide is absorbed in

the damping zone. The wave arriv-

ing at the beginning of the wave-

guide creates an electrical signal in

the coil surrounding the waveguide.

The propagation time of the wave is

used to derive the position. Depend-

ing on the version the corresponding

value is output as a voltage or a cur-

rent either with rising or falling char-

acteristic. This process takes place

with measuring high precision and

repeatability within the stroke range

defined as nominal stroke length.

At the rod end is a damping zone,

within which no reliable signal is

available, but which may be entered

by the magnet.

The electrical connection between

the transducer, the processor/con-

troller and the power supply is via a

cable, which depending on the ver-

sion is either fixed or connected

using a female connector.

2 Function and Characteristics

Dimensions for installing the

Micropulse transducer:

➥➥

➥➥

➥ Fig. 3-2

Dimensions for installing the mag-

net:

➥➥

➥➥

➥ Fig. 3-4

2.3 Available stroke lengths

and magnets

To provide for optimum fit in any

application, a wide range of stan-

dard stroke lengths and magnets in

various form factors are available.

Magnets must therefore be ordered

separately.

The following nominal stroke

lengths are available:

Stroke lengths

[mm]

Increments

[mm]

50 ... 500 25

500 ... 1000 50

1000 ... 2000 100

2000 ... 4000 250

Other stroke lengths on request.

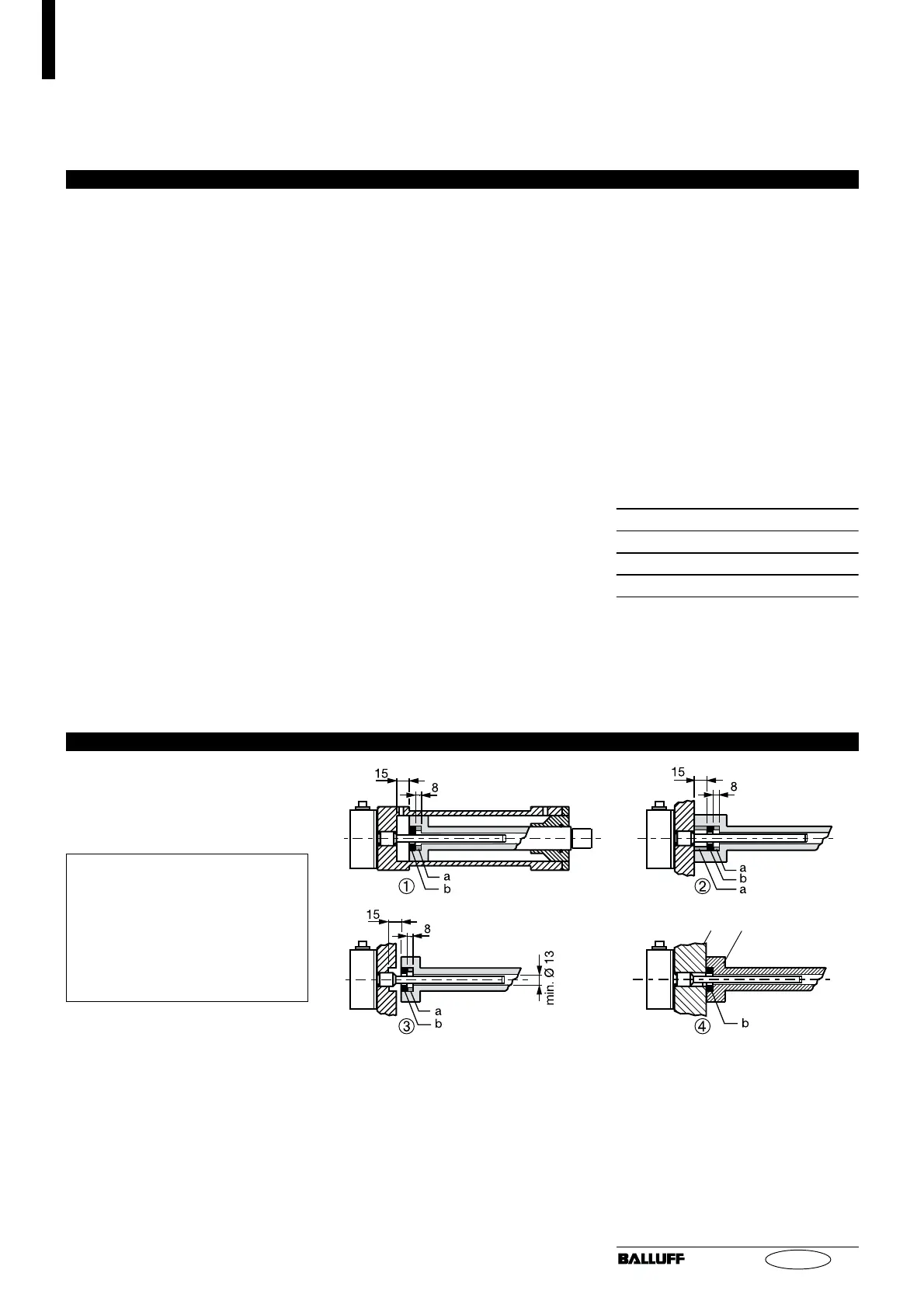

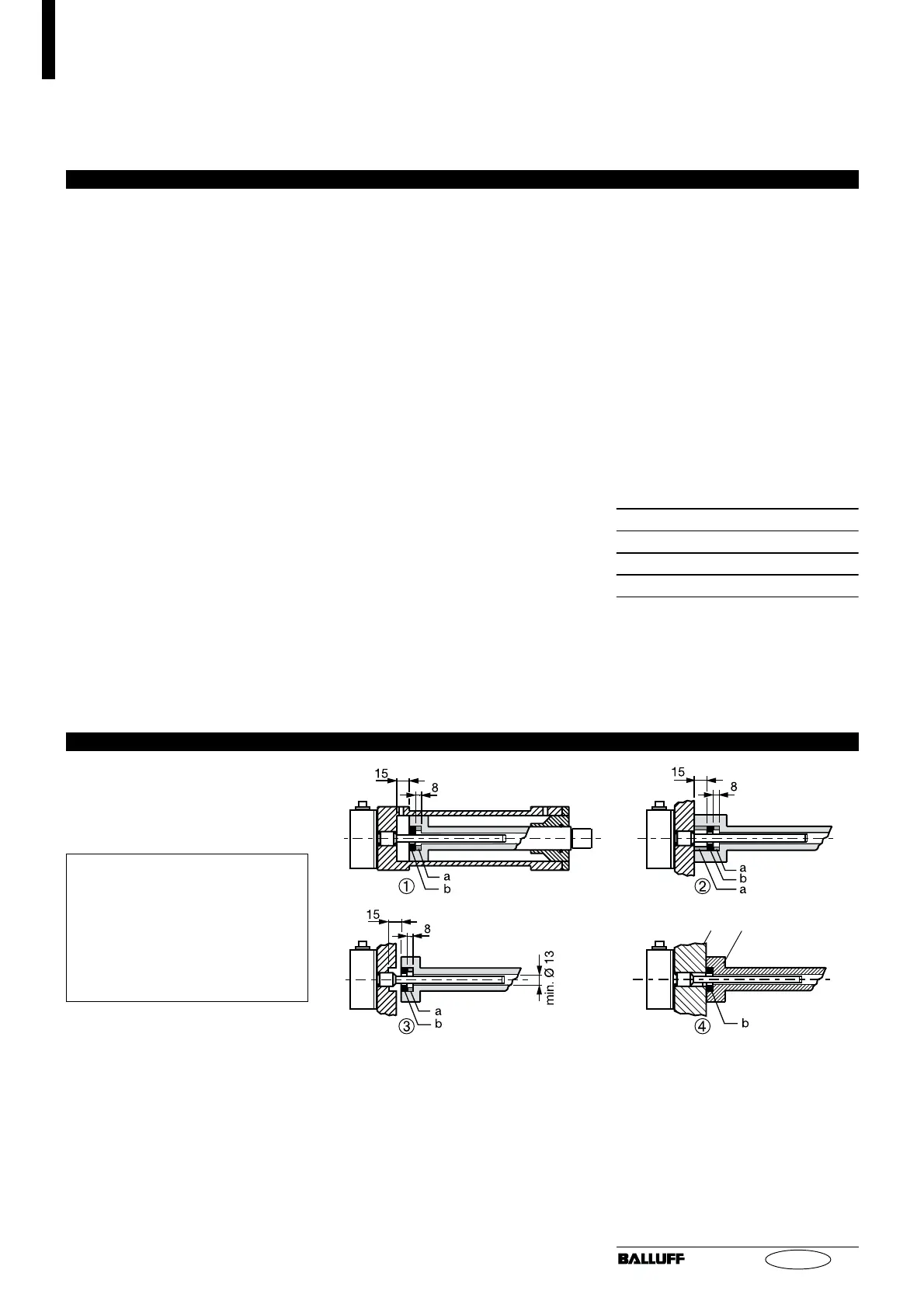

3 Installation

3.1 Mounting

When possible, use non-magnetiz-

able material for attaching the trans-

ducer and magnet ring.

➥➥

➥➥

➥ Fig. 3-1.

When attaching the transducer to

magnetizable materials, appro-

priate measures must be taken to

protect against magnetic disturb-

ances

➥➥

➥➥

➥

Fig. 3-1. Note the

recommended distance of the

transducer and cylinder from

strong, external magnetic fields.

Fig. 3-1: Mounting

➀ - ➂ for magnetizable materials

➃ for non-magnetizable materials

a = Spacer made of non-mag-

netizable materials

b = Magnet

non-magnetizable material

Loading...

Loading...