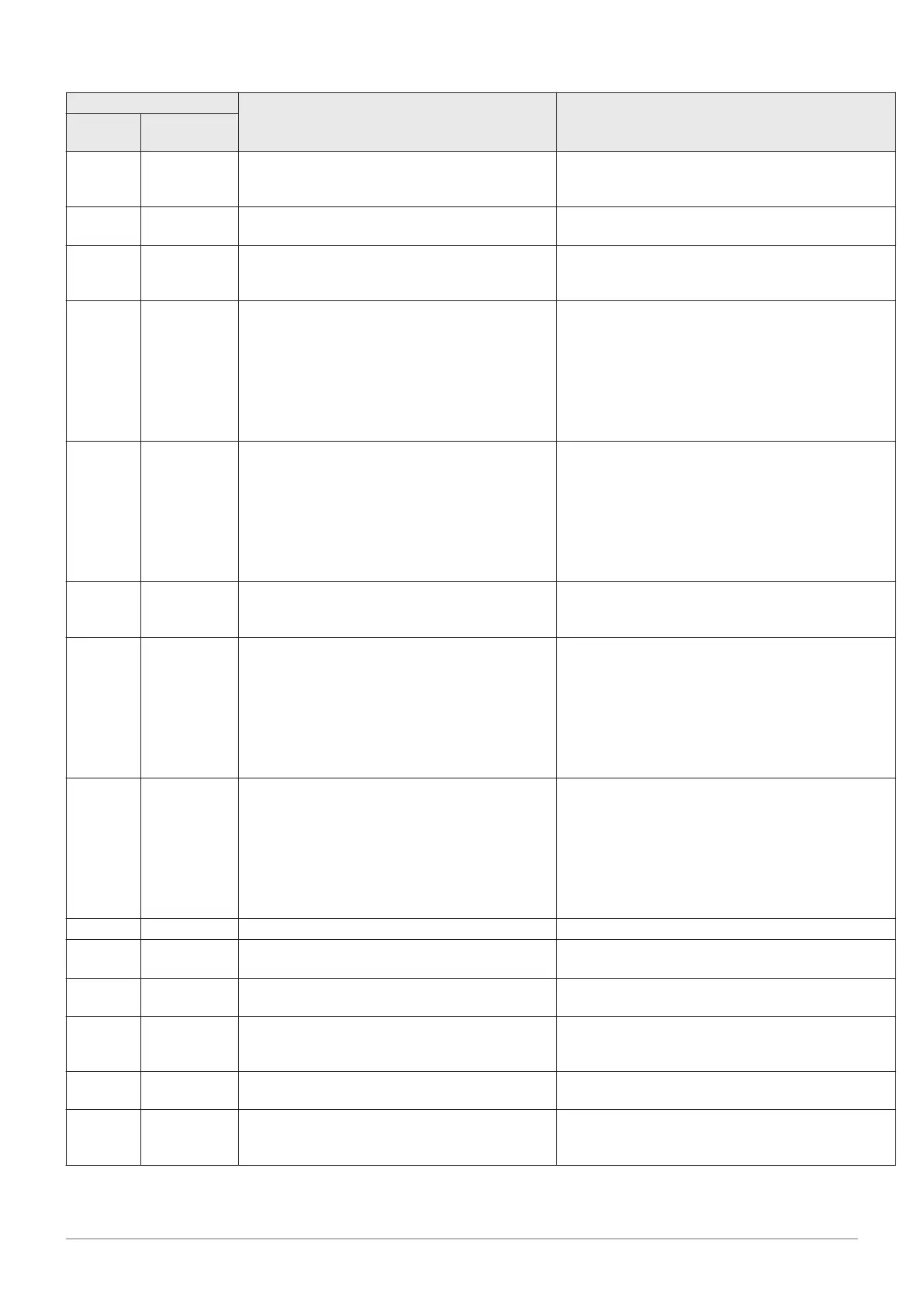

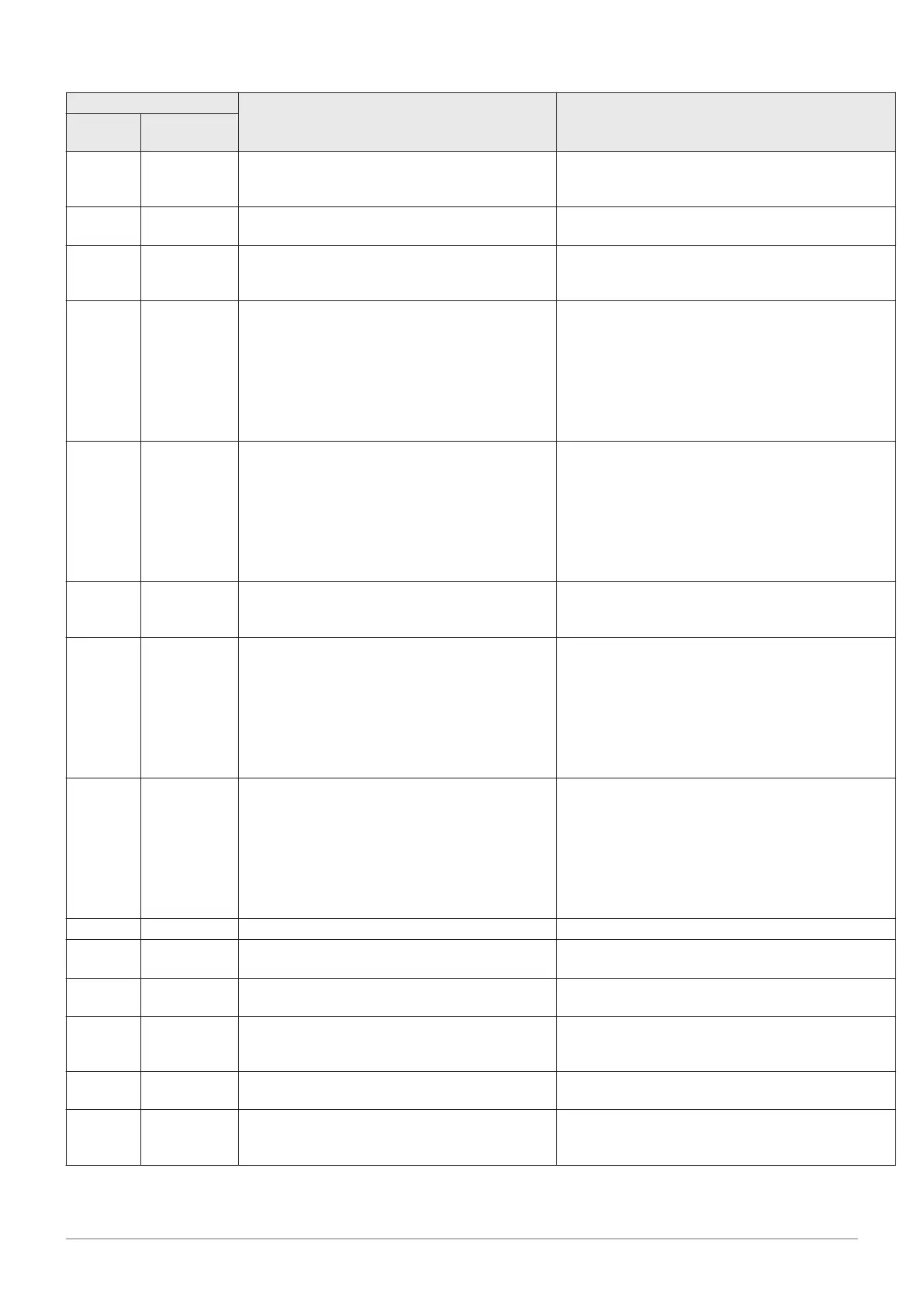

BOILER DISPLAY

DESCRIPTION OF TEMPORARY FAULTS

CAUSE

Check / Solution

Group

code

Specific code

A.02 .76

Internal memory reserved for full customisation of

settings. No further changes can be made

CONFIGURATION ERROR

Re-enter the values CN1 and CN2

Replace the CU-GH board

H.00 .42 Pressure sensor open/faulty

RESET PROCEDURE IN PROGRESS

No action required

H.01 .00

Temporary communication failure between gas

valve and boiler PCB.

MAIN PCB ERROR

Configure CN1/CN2

Replace the main PCB

H.01 .05

Maximum temperature difference value between

flow and return reached.

INSUFFICIENT CIRCULATION

Check the boiler/installation circulation

Activate a manual venting cycle

Check the installation pressure

OTHER CAUSES

Check the cleanliness of the exchanger

Check the operation of the temperature sensors

Check the connection of the temperature sensors

H.01 .08

Flow temperature increase in heating mode too

quick. Temporary stoppage of 10 minutes.

INSUFFICIENT CIRCULATION

Check the boiler/installation circulation

Activate a manual venting cycle

Check the installation pressure

OTHER CAUSES

Check the cleanliness of the exchanger

Check the operation of the temperature sensors

Check the temperature sensor connection

H.01 .14 Maximum flow temperature value reached.

INSUFFICIENT CIRCULATION

Check the boiler/installation circulation

Activate a manual venting cycle

H.01 .18 No water circulation (temporary).

INSUFFICIENT CIRCULATION

Check the installation pressure

Activate a manual venting cycle

Check the operation of the pump

Check the boiler/installation circulation

TEMPERATURE SENSOR ERROR

Check the operation of the temperature sensors

Check the temperature sensor connection

H.01 .21

Flow temperature increase in domestic water

mode too quick. Temporary stoppage of 10 mi

nutes.

INSUFFICIENT CIRCULATION

Check the installation pressure

Activate a manual venting cycle

Check the operation of the pump

Check the boiler/installation circulation

TEMPERATURE SENSOR ERROR

Check the operation of the temperature sensors

Check the connection of the temperature sensors

H.02 .00 Reset in progress

H.02 .02

Waiting for configuration settings to be entered

(CN1,CN2).

CN1/CN2 CONFIGURATION MISSING

Configure CN1/CN2

H.02 .03

Configuration settings (CN1,CN2) not entered

correctly.

Check configuration CN1/CN2 Configure CN1/CN2

correctly

H.02 .04 PCB settings cannot be read.

MAIN PCB ERROR

Configure CN1/CN2

Replace the main PCB

H.02 .05

Setting memory not compatible with the boiler

PCB type

-

H.02 .07 Low pressure in heating circuit (permanently)

Check the system pressure and restore it Check the

pressure of the expansion vessel Check for any sys

tem / boiler leaks

11 Troubleshooting

600 Combi 2 73

Loading...

Loading...