8-1

DMR V4C 3.3 (User Manual) V-4 06-May-2022

8 Theory of Operation

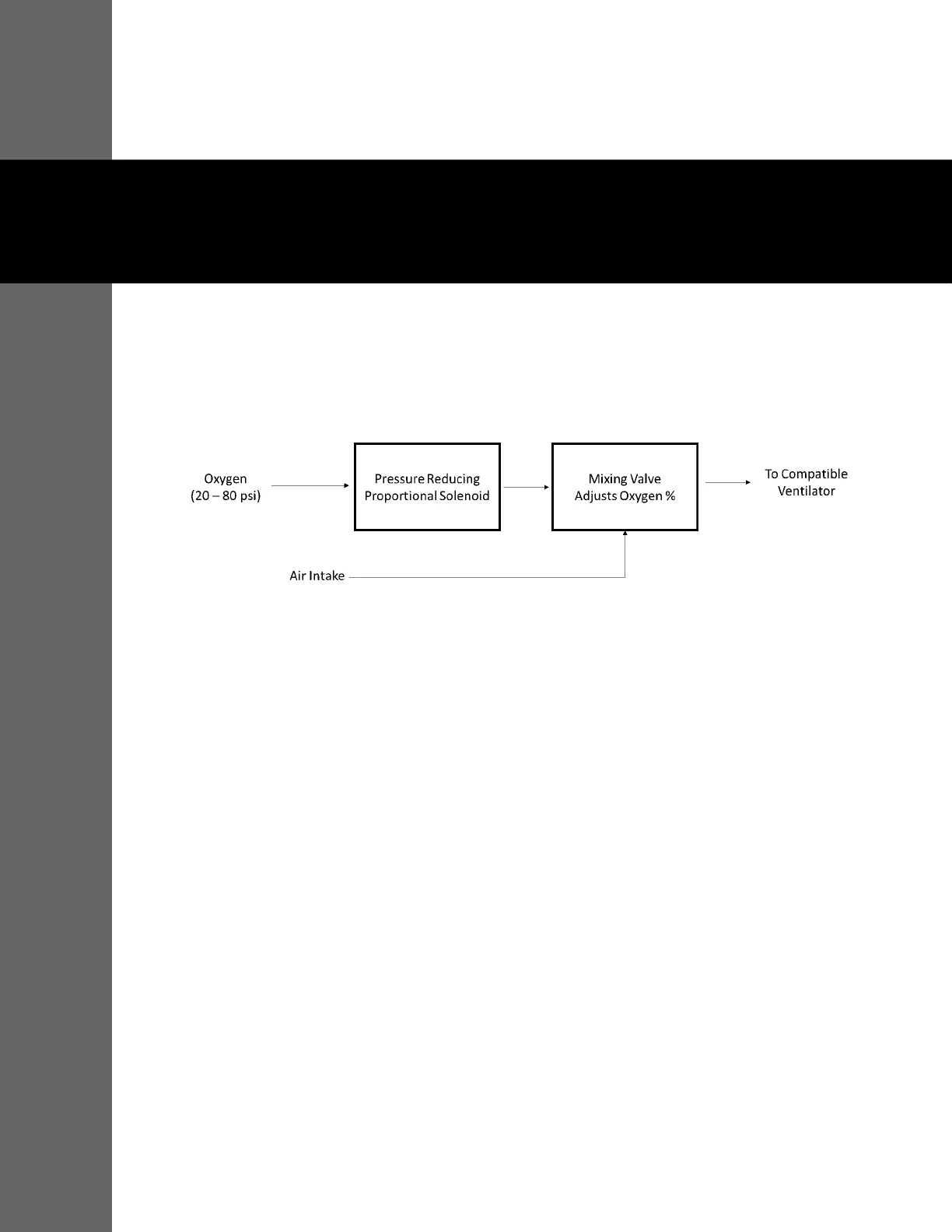

The V4C-O2E Oxygen Mixer is primarily composed of a pressure controlled proportional sole-

noid, which actively controls the pressure of the incoming oxygen over the course of a delivered

breath, and a mixing valve which can be used to adjust the proportion of air and oxygen deliv-

ered to the ventilator.

Figure8-1.V4C-O2E Oxygen Mixer theory of operation

The pressure controlled solenoid actively adjusts the oxygen flow to maintain the appropriate

pressure and flow of oxygen through the Oxygen Mixer for the given FiO

2

settings and breath

parameters.

The Oxygen Mixer is equipped with emergency pressure relief valves which will ensure that

excess pressure does not reach the patient in a fault situation. The Oxygen Mixer is additionally

equipped with vacuum breaking valves, which allow for air ingress into the Oxygen Mixer

should the oxygen supply ever become compromised.

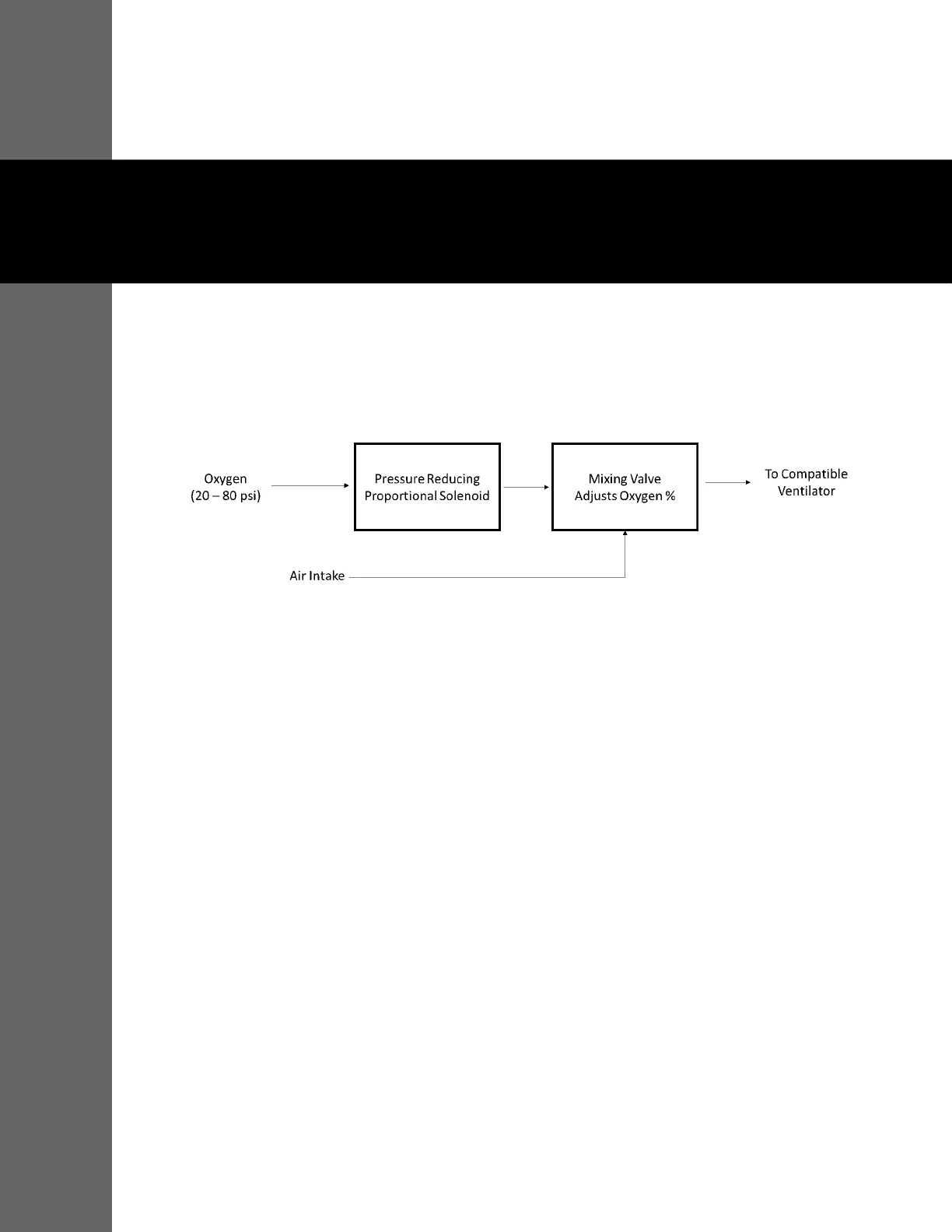

The mixing valve works by moving a gasket back and forth between the air and oxygen gas lines

in order to create the desired oxygen percentage. This motion is controlled by the knob on the

front of the Oxygen Mixer. In a pure oxygen or pure air delivery position the gasket completely

seals one of the gas lines and allows free flow of the other (see Figure 8-1). A clicking sound is

sometimes heard when the gasket releases from one side of the gas pathway, unsealing that

side. This is normal.

Loading...

Loading...