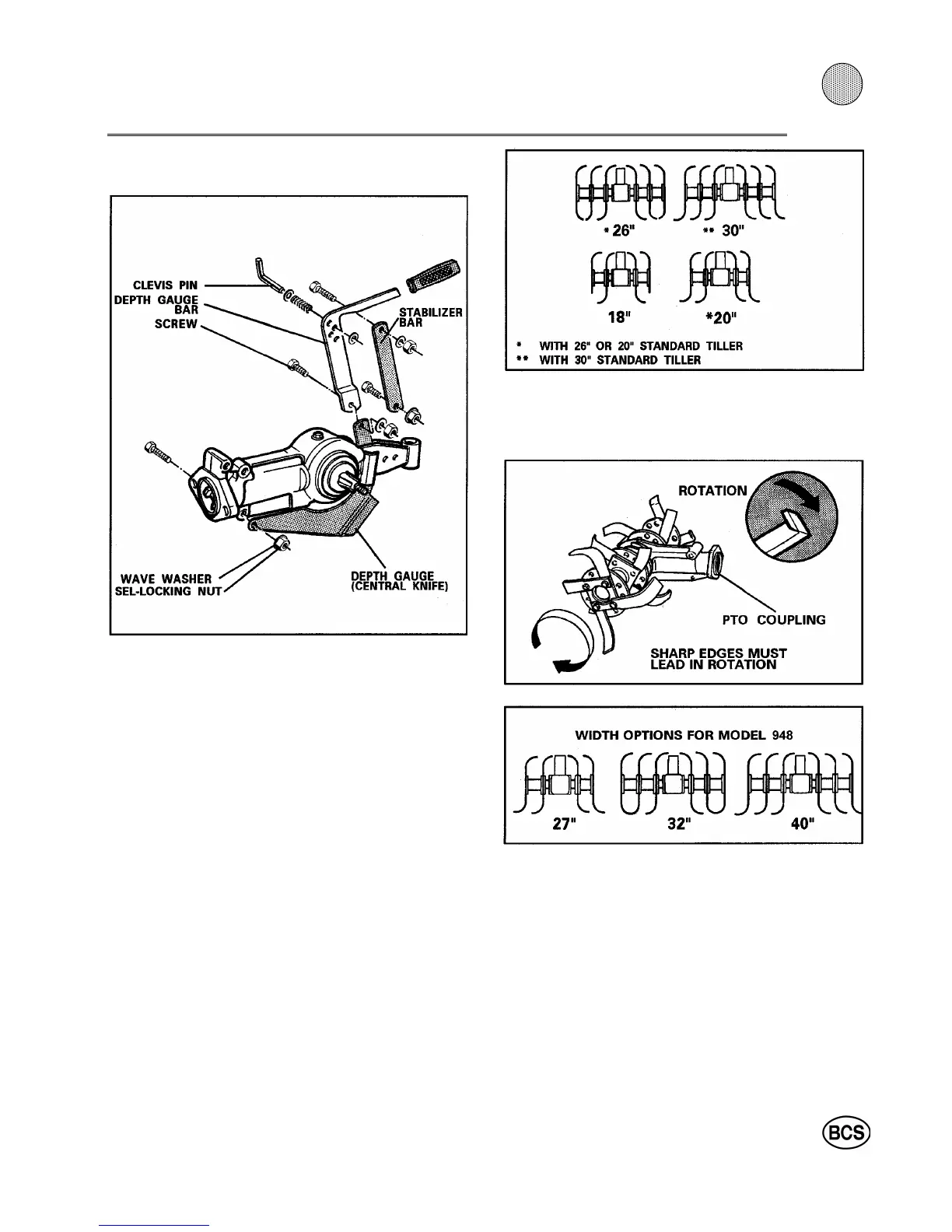

1. Open the carton and stand the tiller on end so you can

see the underside. Fasteners required for assembly are

included. The bolts in the assembly drawing are label-

led (M8 or M10) for the metric diameters and length is

given in millimetres.

If a sulky or utility cart is to be hitched to the tractor, as-

semble the depth gauge bar in a position 180 degrees

from that in the drawing.

2. Use the self-locking nut to fasten the depth gauge to

the gear housing. Install the flange nut at the stabilizer

bar bottom connection.

3. The depth gauge and stabilizer bar protrude through

the top of the tiller housing. The bar is bolted to the bra-

ckets. The gauge is pinned with the clevis pin and "hair-

pin". Tighten all nuts.

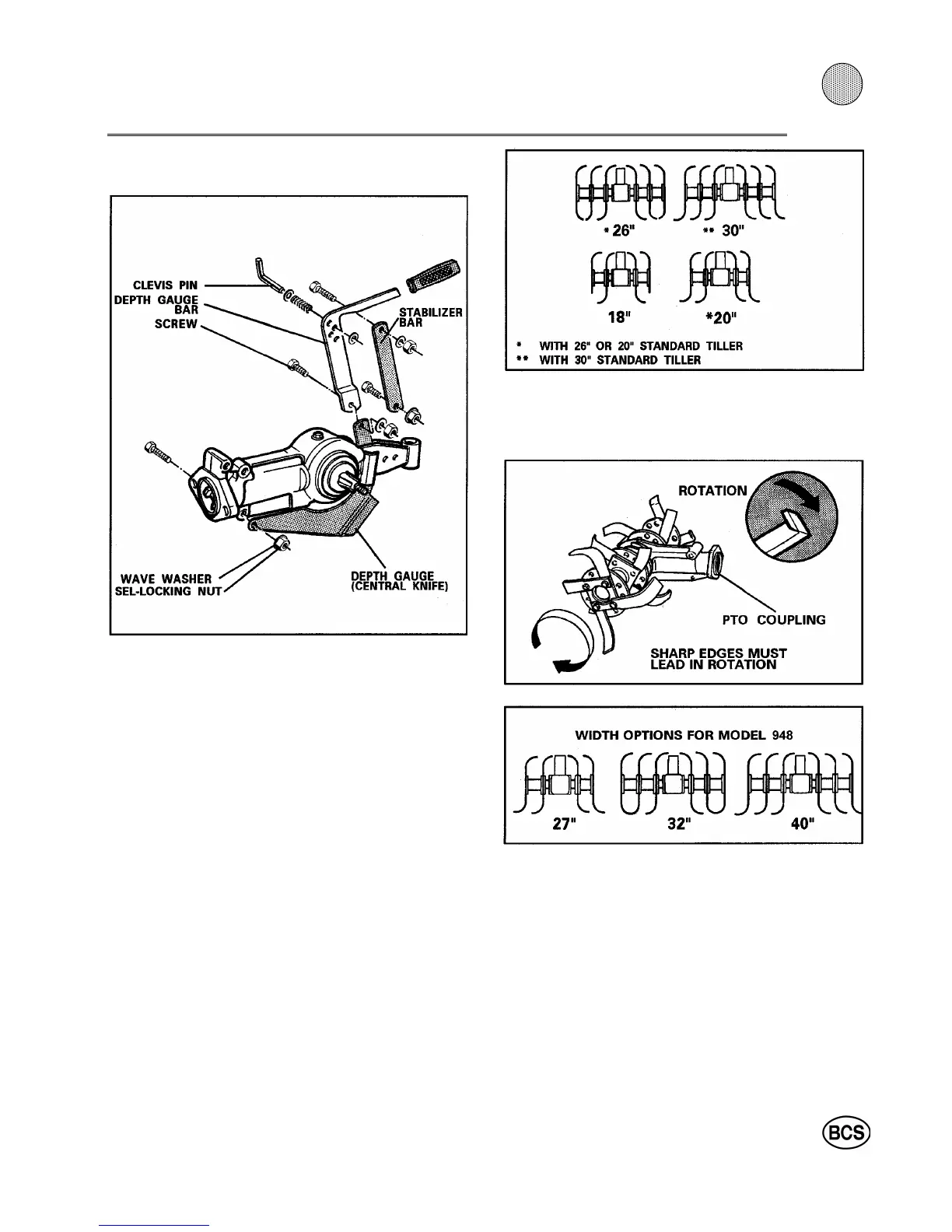

WIDTH OF TILTH

IMPORTANT

When changing sets of tines, it is important to keep

the tines in place on one side for use as a model while

changing tines on the other.

Do not mount the tines backwards on the flange.

SINGLE ROW ATTACHMENT FOR 710, 718, 722, 732

(or converted 852):

Available sizes are 18", 20", 26" and 30".

SINGLE ROW ATTACHMENT FOR MODEL 948:

This comes preassembled for a 32" tilling width. The

width can be increased to 40" or decreased to 27" by

adding or removing flanges of tines, and by changing

the tines to bend inward or outward (see drawing).

TILLING DEPTH ADJUSTMENT

The procedure is the opposite of what many people first

would believe. For the deepest soil penetration, you rai-

se the depth controlling "knife" by pinning the bar in the

bottom hole (see drawing).

37

3

Loading...

Loading...