ENGLISH

18 BD LASER MAX Man. cod. B409652FG Class C Solutions Group

MAINTENANCE, DISMANTLING AND DISPOSAL

9Maintenance, Dismantling and disposal

Warning: IMPORTANT!

Before carrying out any maintenance operation you

must turn OFF the power and disconnect the power cord.

Maintenance must be carried out only by qualified per-

sonnel equipped with appropriate protective devices

for safe work.

Always use original Class C Solutions Group spare parts.

9.1.0 General information

9.1.1 Skills of maintenance personnel

The machine operator must be knowledgeable about machine opera-

tion.

9.1.2 Type of Maintenance

Ordinary Maintenance

• Servicing operations that must be carried out periodically

by the machine operator.

• The purpose of ordinary maintenance is guarantee regular

functioning of the machine and a consistent quality of the

product.

• The maintenance schedule may vary in relation to work or

environmental conditions in the place of installation.

Complex Maintenance

• Complex maintenance consists of actions to be taken only

when given conditions occur (break downs, failures,

replacement of parts).

• Due to the complex nature of such actions and the special

tools required, we recommend you should contact

qualified personnel from or authorized by Class C

Solutions Group.

9.2.0 Ordinary maintenance

We recommend inspecting the machine periodically and replace worn

parts.

9.2.1 Checking and cleaning the fan

It is suggested to periodically check the cleaning level of the air grids

and make sure that there is no accumulated dust that could obstruct

the air passage.

Poor ventilation could cause a machine overheating

and damage the components.

9.2.2 Cleaning the working area

At the end of each working day clean the machine removing scrap and

burrs to ensure proper functioning of the machine and to prevent any

damage to its parts.

Empty the shaving collection drawer every time that the work surface

is cleaned or whenever it is full of shavings.

Do not clean the machine with compressed air.

9.2.3 Cleaning the display

To clean the Touch Screen display we recommend using a micro-fibre

cloth; avoid using substances that contain alcohol or solvents.

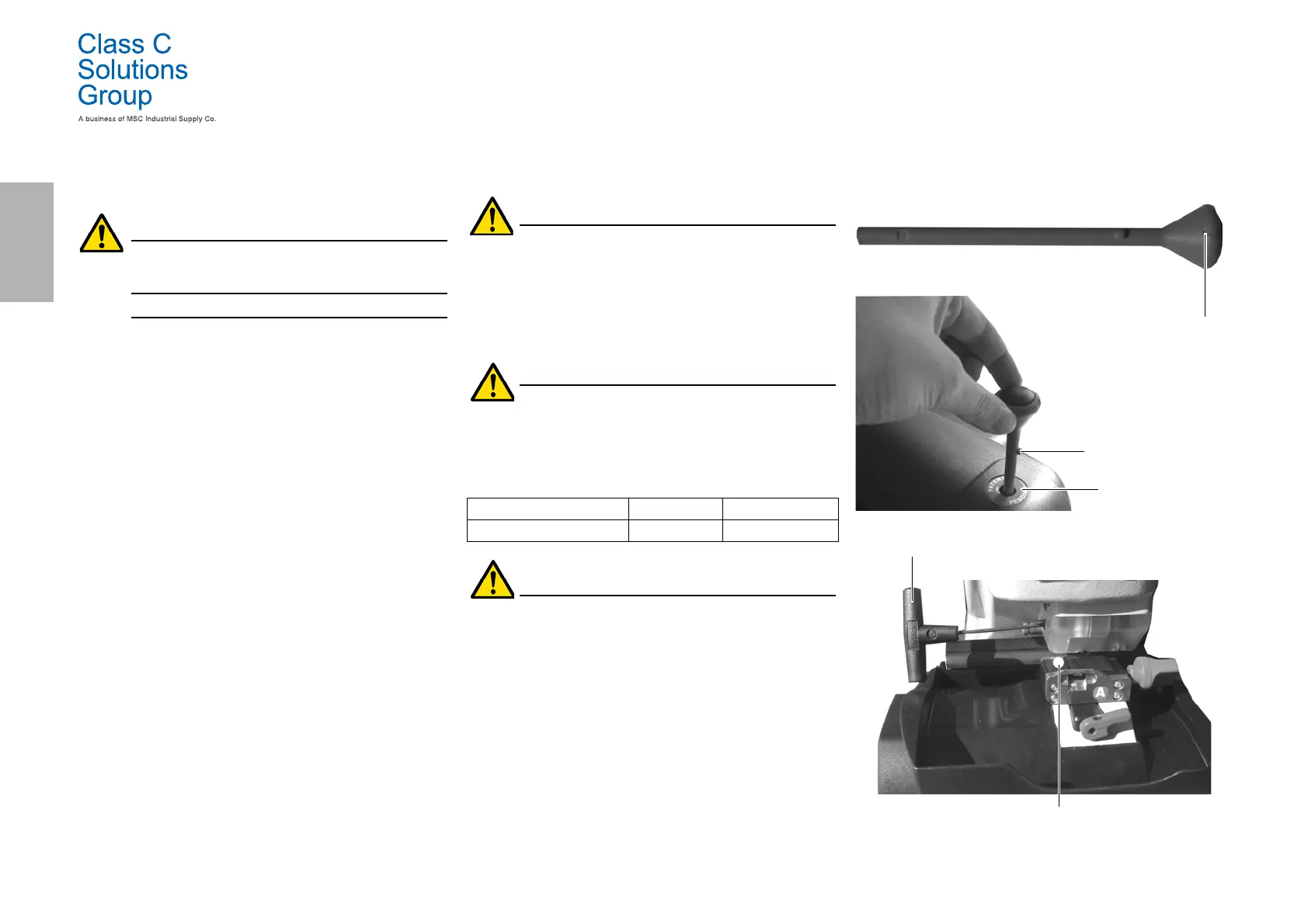

9.2.4 Replacing the milling cutter

Before carrying out this operation disconnect the

power cable from the mains.

Required tools when replacing the fuses

•Patent pending.

• 1 T- Handle hexagon wrench (long) 3mm.

How to proceed:

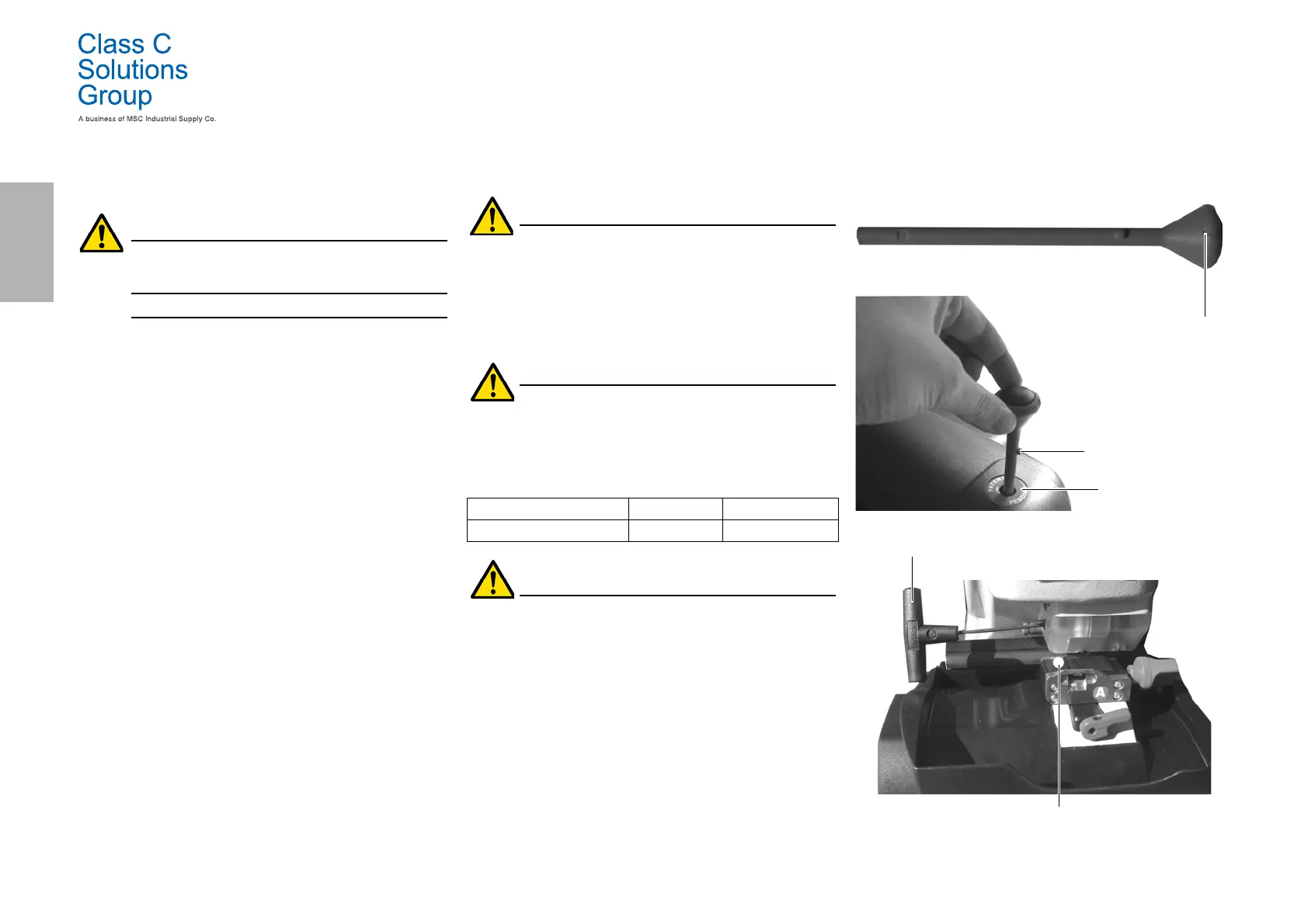

• insert the bar to remove the cutter into the “Patent

pending” seat;

• rotate the bar slowly until the bar ‘tooth’ fits into the slot

located inside the “Patent pending” seat;

• rotate the bar: the triangular mark on top of the bar will

point to the left;

• insert the T-shaped 3 mm hexagon wrench in the hole to

unlock the cutter (see picture in the next screen);

• loosen the nut that fastens the cutter;

• pull out the bar from the “patent pending” seat and remove

the cutter.

Spare part description Code Frequency

Milling cutter 2,5mm RIC03304B When required

Bar ‘tooth’ to

Patent pending

Triangular mark

replace the cutter

T- Handle hexagon wrench (long) 3mm

Cutter calibration cut out

Loading...

Loading...