ENGLISH

20 BD LASER MAX Man. cod. B409652FG Class C Solutions Group

MAINTENANCE, DISMANTLING AND DISPOSAL

9.2.7 Inspecting and replacing the fuses

The BD LASER MAX key duplicating machine is equipped with 2 fuses

located in the power unit next to the switch, which have the purpose

to protect the machine from surges and short circuit.

If the machine fails to start after you have turned on the main switch,

we recommend you inspect the fuses in the power unit and replace

them if needed.

Required tools when replacing the fuses

• Tester, ohm meter, multimeter etc (to measure fuses’

continuity).

•Screwdriver.

Before carrying out this operation disconnect the

power cable from the mains.

How to proceed:

• press slightly on the tongues of the fuse carrier to pull it

out from its seat;

•inspect the fuses;

• replace any damaged fuse with a new one of the same

capacity (Amperage) and type (slow);

• put back the fuse carrier into its seat.

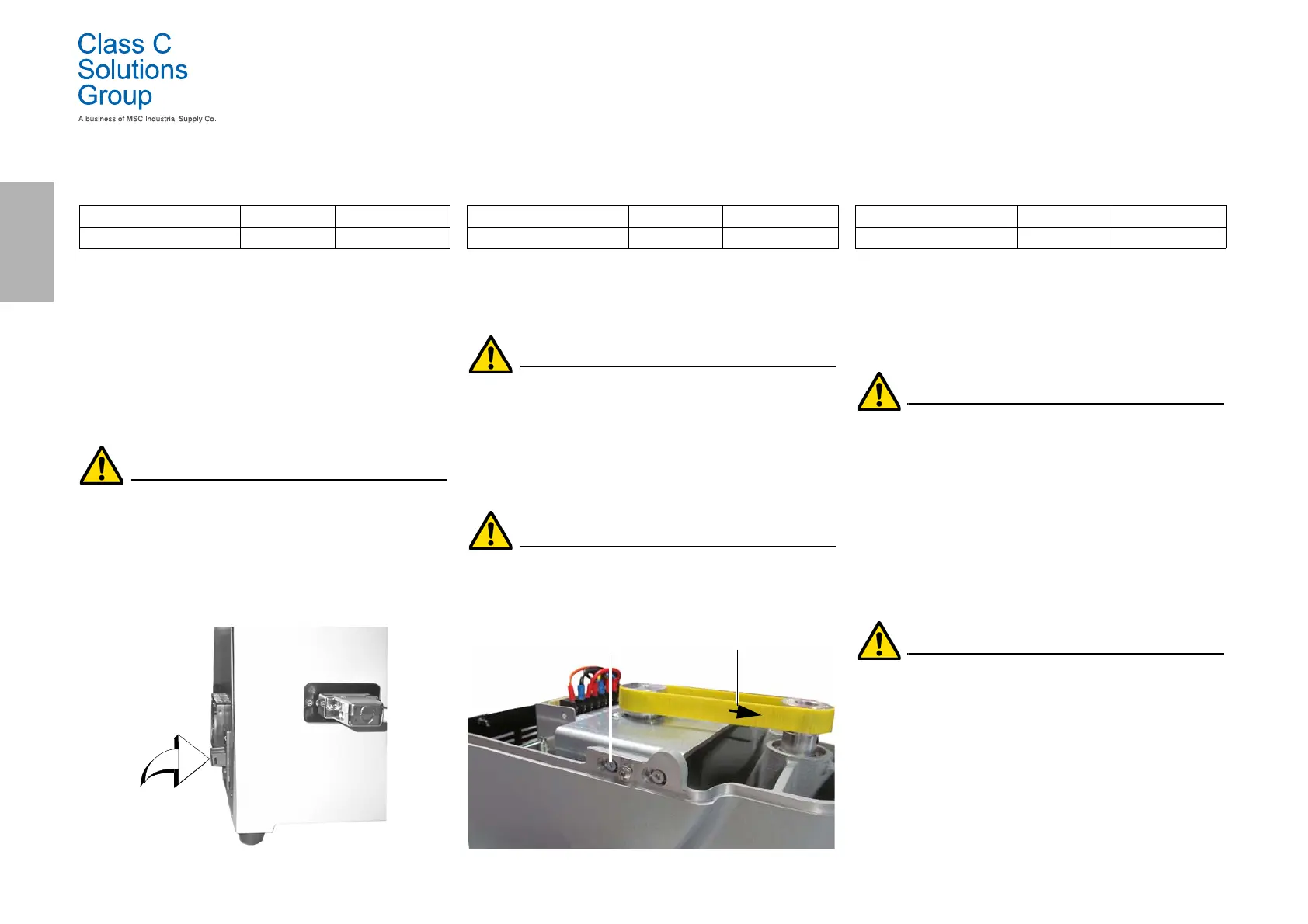

9.2.8 Replacing the motor belt

Required tools

• 3mm hexagon wrench.

Safety warning

Before carrying out this operation disconnect the

power cable from the mains.

How to proceed:

• remove the top cover;

• use the 3mm hexagon wrench to loosen the 4 screws that

fasten the motor supporting unit;

• pull the motor supporting unit gently towards you to

reduce the belt tension;

• remove the belt from its seat and replace it with a new one.

When installing the belt again, make sure you respect

the direction marked by the arrow.

• put the motor supporting unit back into its initial position

and adjust the belt tension;

• fasten by tightening the 4 screws, put the back cover back

into its initial position and lock it.

9.2.9 Replacing the X axis sensor

Required tools

•2mm hexagon wrench.

• 13mm adjustable wrench.

Safety warning

Before carrying out this operation disconnect the

power cable from the mains.

How to proceed:

• remove the back cover and the protection grid of the card

and cut the straps;

• disconnect the cable from the electronic card;

• remove the bottom cover;

• use the adjustable wrench to loosen the nut that fastens

the sensor;

• unscrew and remove the sensor and replace it with a new

one;

• after fastening and locking the new sensor, move the

carriage towards it using the relevant controls.

IMPORTANT! Leave 0.02mm clearance between point A

and B.

• put back the bottom cover into its initial position and

fasten it;

• connect the cable of the new sensor to the electronic card;

• fix the cables with new straps;

• close the rear carter and the protection grid of the card and

fix them.

Spare part description Code Frequency

Rapid fuse 4A 5x20 RIC02592B When required

Spare part description Code Frequency

Belt 15X334-994 RIC03304B When required

Fastening screws

Arrow indicating direction

Spare part description Code Frequency

X axis sensor-994 RIC03306B When required

Loading...

Loading...